Choosing between GCL and HDPE is a high-stakes decision. The wrong liner can lead to catastrophic leaks, costly repairs, and environmental compliance failures, jeopardizing your entire project.

Choose GCL for its self-healing properties in applications with soil cover, like landfills. Choose HDPE for its absolute impermeability and superior strength in harsh environments like ponds or chemical containment. Often, a composite system using both is the safest solution.

This isn't a simple "good vs. bad" comparison. Both GCL and HDPE are excellent engineering tools, but they function in fundamentally different ways. The belief that one is universally superior is a common and costly mistake among importers and contractors. To make the right investment, you need to understand their core differences, from how they stop water to how they handle on-site stress. Let's break it down.

What are the main differences between GCL (Geosynthetic Clay Liner) and HDPE geomembranes?

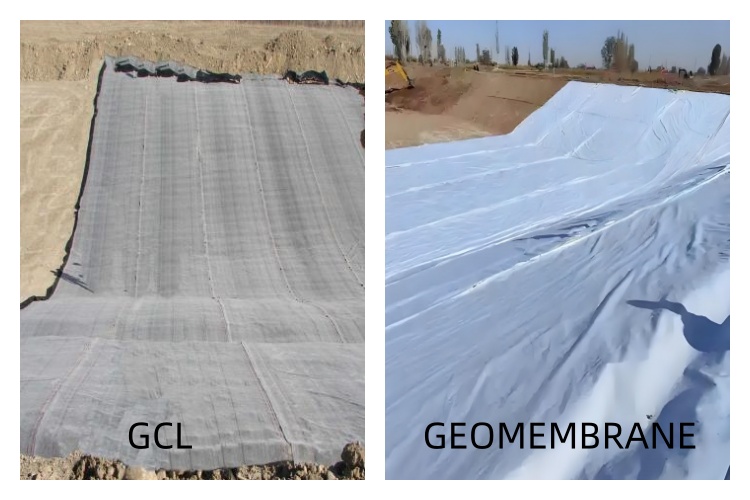

You see two liner products, but their technical sheets are vastly different. Misinterpreting their core functions can lead you to specify a product that is completely unsuitable for your site's conditions.

A GCL is an "active" barrier that uses swelling bentonite clay to create a low-permeability seal. An HDPE geomembrane is a "passive" barrier—an impermeable plastic sheet that physically stops water. This fundamental difference dictates their performance, strengths, and weaknesses.

Understanding how each liner works is the first step to choosing correctly. Their barrier mechanisms are worlds apart, which directly impacts everything from puncture resistance to long-term reliability.

| Feature | GCL (Geosynthetic Clay Liner) | HDPE Geomembrane |

|---|---|---|

| Barrier Mechanism | Active: Bentonite clay swells when hydrated to form a seal. | Passive: Solid, non-porous plastic sheet acts as a physical barrier. |

| Self-Healing | Yes. Swelling clay can seal minor punctures automatically. | No. Any puncture or tear requires manual patch repair. |

| Puncture Resistance | Lower. Relies on protective layers to prevent damage. | High. Strong resistance to puncture and mechanical stress. |

| Hydraulic Perf. | Low permeability (10⁻¹¹ m/s) when properly hydrated. | Extremely low permeability (<10⁻¹³ m/s) with proper seams. |

How do I decide whether GCL or HDPE is better suited for my specific project conditions?

You know the technical differences, but how do they apply to your real-world project? Using a liner in the wrong environment is a recipe for failure, even if the product itself is high quality.

HDPE excels in exposed, high-stress, or chemically aggressive applications like reservoirs or secondary containment. GCL performs best when consistently hydrated and protected by a soil cover (overburden), where it offers unique self-healing benefits for applications like landfills.

The environment dictates the choice. A liner that thrives in one setting will fail in another.

When to Choose GCL:

GCL is the ideal choice when these conditions are met:

- Constant Hydration: The bentonite must stay moist to maintain its seal. It is not suitable for areas with severe wet/dry cycles without a protective cover.

- Sufficient Overburden: GCL requires the weight of a soil cover (confining pressure) to ensure the clay swells correctly and to protect it from puncture and UV degradation.

- High Settlement Expected: The flexibility of a GCL allows it to accommodate differential settlement better than a more rigid polymer sheet might.

- Prime Application: Landfill base liners (under a primary HDPE liner), underground structures, and artificial lakes where a natural soil bottom is desired.

When to Choose HDPE:

HDPE is the superior choice for more demanding and exposed applications:

- Chemical & UV Exposure: HDPE offers excellent resistance to a wide range of chemicals and can be formulated for long-term UV stability, making it perfect for exposed ponds, reservoirs, and industrial lagoons.

- High Mechanical Stress: In applications like heap leach pads or canals with high flow rates, HDPE's superior puncture and tear resistance is critical.

- Absolute Impermeability Required: For hazardous waste containment or situations where zero leakage is the standard, a properly welded HDPE liner provides the most secure barrier.

What factors—such as installation, cost, and durability—should I compare before choosing between GCL and HDPE?

Focusing only on the per-square-meter material cost is a classic error. Installation complexity, labor skills, and equipment needs can drastically alter the total project budget and timeline.

GCL is generally faster and cheaper to install, requiring no specialized welding equipment. HDPE offers superior long-term durability but demands skilled technicians for thermal welding and rigorous quality control, increasing initial time and labor costs.

A true cost-benefit analysis must include the entire installation process and the liner's expected lifespan. A lower material cost can easily be erased by higher labor costs or a shorter service life.

| Factor | GCL (Geosynthetic Clay Liner) | HDPE Geomembrane |

|---|---|---|

| Installation Speed | Fast. Panels are unrolled and overlapped. | Slower. Requires precise panel layout, welding, and testing. |

| Required Labor | Low skill. General laborers can deploy it. | High skill. Requires certified welding technicians. |

| Equipment Needs | Basic handling equipment. | Specialized hot-wedge and extrusion welders. |

| Total Installed Cost | Lower upfront cost due to faster, simpler installation. | Higher upfront cost due to specialized labor and QC. |

| Long-Term Durability | Good, but vulnerable to desiccation and ion exchange. | Excellent. Superior resistance to aging, chemicals, and UV. |

How can I ensure long-term waterproofing performance and environmental compliance when selecting between GCL and HDPE?

Your choice is made, but the job isn't done. Failing to guarantee performance opens you to long-term liability. You need a strategy to ensure the liner system functions perfectly for decades.

For HDPE, the key is rigorous seam quality control (QC) via air pressure and destructive testing. For GCL, ensure proper hydration and sufficient confining pressure. For maximum security and compliance, a composite liner system is the industry's best practice.

For critical applications like landfills or hazardous waste containment, you should not think of it as an "either/or" choice. The safest and most common solution specified by engineers worldwide is a composite liner: a primary HDPE geomembrane installed directly on top of a secondary GCL.

This system combines the best of both worlds:

- Redundancy: The HDPE provides the primary, absolute barrier. The GCL acts as a robust secondary barrier.

- Enhanced Safety: If a small defect or puncture ever develops in the HDPE liner over time, the underlying GCL will hydrate and swell to seal the leak, preventing any environmental contamination.

- Protection: The HDPE geomembrane shields the GCL from desiccation (drying out) and chemical attack, ensuring the bentonite's long-term integrity.

By combining the two materials, you create a system that is far more reliable than either material used alone.

Conclusion

Neither GCL nor HDPE is universally "better." Choose GCL for its self-healing ability under soil, or HDPE for its superior strength. For critical applications, combine them in a composite system.