LLDPE Geomembrane — Manufacturer, Specifications & Solution

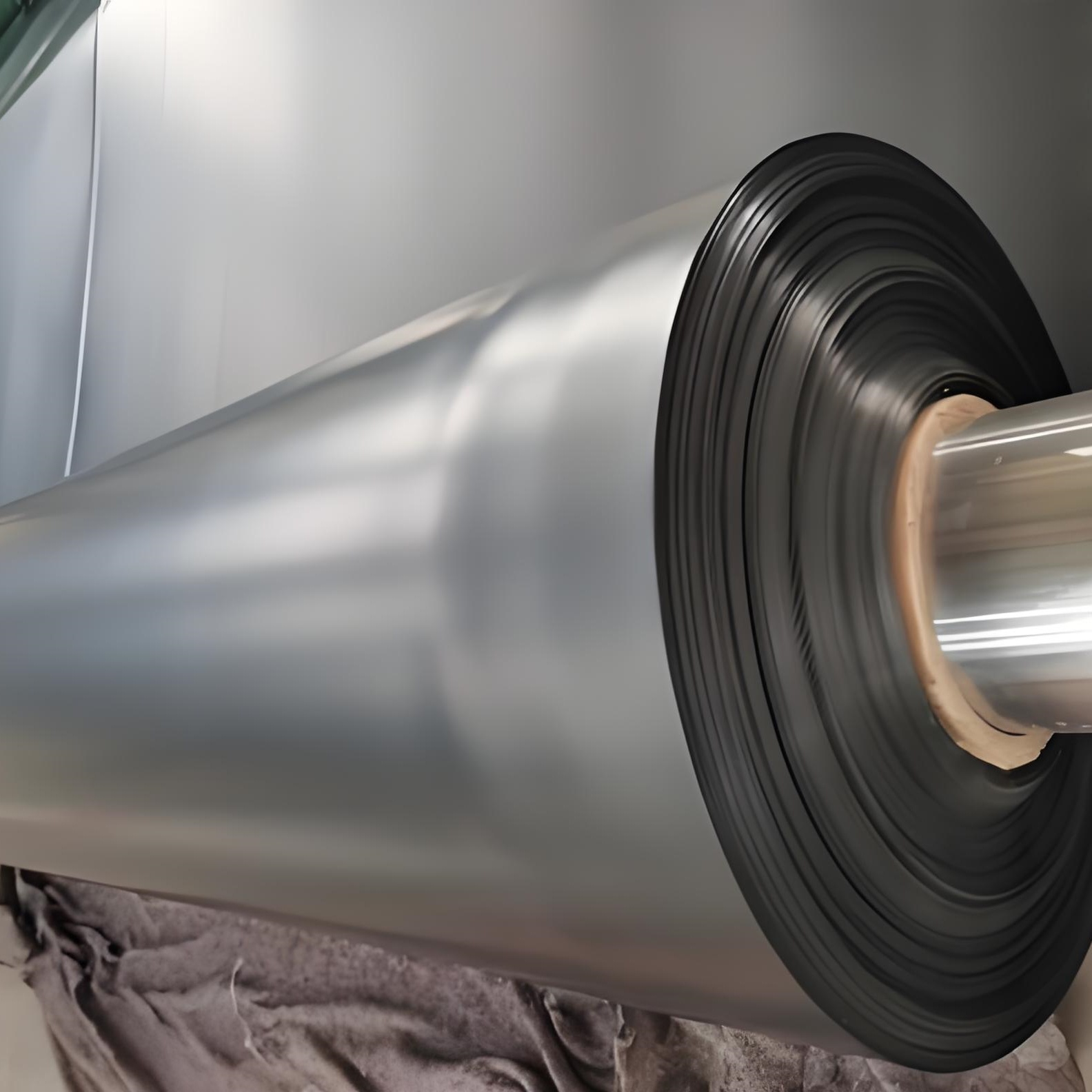

Linear low-density polyethylene liners for ponds, canals, and reservoirs. Flexible & puncture-resistant, smooth or textured, 0.3–3 mm, factory-direct supply and reliable QA.

Référence ASTM/GRI/ISO

Usine directement

Exporter à l'échelle mondiale

Propriétés principales de Géomembrane LLDPE

LLDPE geomembrane can stretch over uneven ground and adapt to settlement or deformation without cracking.

While slightly lower than HDPE, LLDPE still offers adequate puncture resistance for ponds, canals, and light-duty containment projects.

Stable against common acids, alkalis, and salts, with good performance in outdoor projects.

Ideal for ponds, canals, and slopes where flexibility is more critical than tensile strength.

LLDPE provides a lower-cost alternative to HDPE for projects that require flexibility over long-term high-strength performance.

Apprenez à connaître Géomembrane LLDPE

LLDPE geomembrane (Linear Low-Density Polyethylene liner) is a flexible, impermeable plastic sheet used as a barrier for ponds, canals, reservoirs, and light-duty landfill projects.

LLDPE geomembrane material is made from linear low-density polyethylene with added stabilizers. It combines flexibility, elongation, and chemical resistance, making it suitable for uneven ground conditions.

Typical LLDPE geomembrane thickness ranges from 0.3 mm to 3.0 mm (200 micron to 3.0 mm). Common specifications include 0.5 mm, 1.0 mm, 1.5 mm, and 2.0 mm, supplied in rolls or sheets.

LLDPE geomembrane is mainly used for seepage prevention and isolation in a wide range of civil, environmental, and water projects, such as:

Décharges and wastewater/sludge treatment sites (LLDPE geomembrane for landfill)

River dikes, dams, tailings dams, sewage ponds, reservoirs, canals, and liquid storage pits/mines (LLDPE geomembrane for dam lining)

Subway tunnels, underground basements, and lining for underground structures

Roadbeds and other foundations requiring salt-resistance or anti-seepage protection

Horizontal and vertical seepage barriers for dams, cofferdams, and waste disposal sites

Aquaculture ponds for seawater and freshwater fish/shrimp farming (LLDPE geomembrane pond liner)

Highways, expressways, and railway foundations, as waterproofing layers for expansive or collapsible soils

LLDPE geomembrane is valued for its flexibility, adaptability to irregular ground, and effective impermeability, making it a cost-efficient liner for both water and waste containment.

The service life of LLDPE geomembrane is typically 10–20 years, depending on thickness, UV exposure, and installation conditions. For long-term heavy-duty projects, HDPE may offer longer durability.

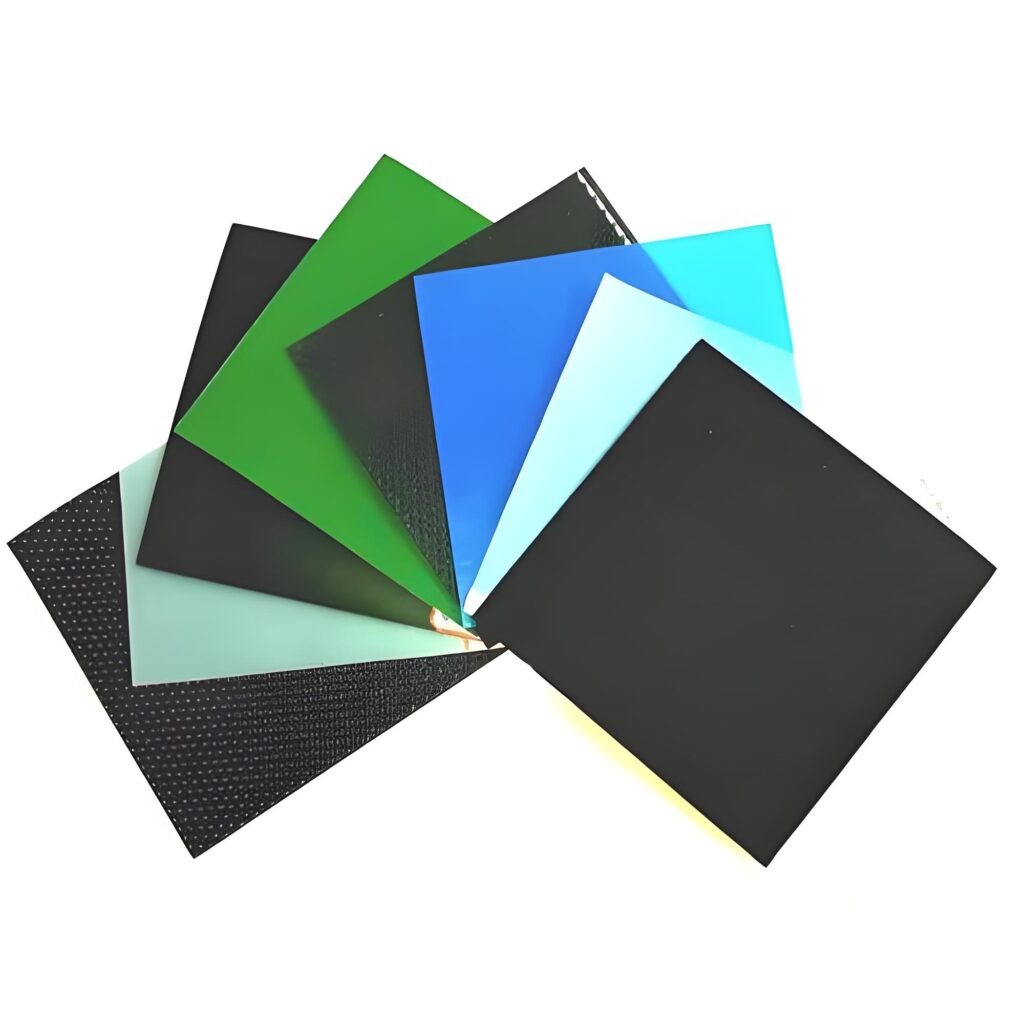

Types de surfaces et options de couleurs of LLDPE Geomembrane

Smooth LLDPE Geomembrane

Smooth on both sides, low friction coefficient.Easy to clean and test leakage; ideal for flat and low-slope projects such as reservoirs, canals, and decorative ponds

Single-Sided Textured LLDPE Geomembrane

One smooth side, one embossed side (dots, diamond, or cross pattern).Increases friction with soil or cover layers; suitable for light to medium slope anti-slip applications

Double-Sided Textured LLDPE Geomembrane

Embossed texture on both sides.Maximizes friction and interface shear strength; used for steep slopes, high load areas, and sidewall stabilization

Black LLDPE Geomembrane

The most common choice, containing carbon black to enhance UV resistance and aging performance. Suitable for all general anti-seepage applications including ponds, canals, and reservoirs.

Blue LLDPE Geomembrane

Improves the visual effect of water bodies, widely applied in decorative ponds, artificial lakes, and premium landscape water projects.

Green HDPE Geomembrane

Blends with natural surroundings, suitable for ecological restoration, wetland protection, and agricultural irrigation projects.

White LLDPE Geomembrane

Reflects sunlight and helps reduce liner surface temperature, minimizing wrinkles caused by thermal expansion and contraction. Often used in tropical or high-temperature regions.

LLDPE Geomembrane Thickness Guide et applications

| Épaisseur (mm) | Principales caractéristiques de performance | Applications typiques | Spécifications et remarques recommandées |

|---|---|---|---|

| 00,50 mm (200 micron LLDPE geomembrane sheet) |

• Basic impermeability with high flexibility • Excellent elongation; conforms to fine ground conditions |

• Small ecological ponds, garden water features • Farmland irrigation micro-canals • Seasonal or temporary water storage |

• Use 30–50 g/m² nonwoven geotextile protection • Avoid sharp objects/heavy mechanical loads |

| 00,75 mm LLDPE geomembrane roll |

• Improved seepage control • Medium puncture & tensile strength; good UV resistance |

• Medium-size fish & aquaculture ponds (LLDPE geomembrane pond liner) • Agricultural drainage canals • Reclaimed water collection tanks |

• Lay on flat subgrade • Single-textured surface for slopes < 5° |

| 1,00 mm Geomembrane LLDPE |

• Common, cost-effective thickness • Strong impact & puncture resistance |

• Irrigation & drainage systems • Small leachate collection ponds • Municipal stormwater tanks |

• Smooth or single-textured per friction need • Add 10 cm sand cushion or geotextile isolation |

| 1,20 mm LLDPE geomembrane liner |

• Higher puncture resistance • Good chemical & aging resistance |

• Sewage treatment pond lining • Basement wall drainage layer • Light-to-medium tailings dam lining |

• Combine with nonwoven geotextile for extra protection • Use textured side toward contact surface to increase friction |

| 1,50 mm LLDPE geomembrane sheet |

• Excellent tensile & puncture performance • Impact and root-penetration resistant |

• Medium landfill lining & capping (LLDPE geomembrane for landfill) • Medium tailings dam liners • Chemical wastewater ponds |

• Prefer double-textured for 5–15° slopes • Leak testing via air-pressure or spark testing |

| 2,00 mm Geomembrane LLDPE |

• Engineering-grade thickness • High resistance to puncture, chemical corrosion & aging |

• Large sludge thickening tanks • Hazardous waste secondary containment • Long-term exposed projects in hot/UV-intense climates |

• Pair with high-strength geotextile for multi-layer barrier • Automated welding for stable seams |

| 2,50 à 3,00 mm Geomembrane LLDPE |

• For extreme conditions • Superior puncture, stress-crack & impact resistance |

• Nuclear waste storage • Heavy-metal tailings dams • Deep foundation waterproofing & drainage |

• Multi-layer composite/reinforced structures; professional installation required • Service life can exceed 30+ years |

LLDPE Geomembrane Specifications, Tests et fiche technique

| Propriété | Méthode de test (réf.) | Valeur typique / Min | Note |

|---|---|---|---|

| Densité | ASTM D1505 | 0.915–0.935 g/cm³ | LLDPE geomembrane density |

| Tensile Properties (yield & break) | ASTM D6693 | Yield ≥ 11 kN/m Break ≥ 16 kN/m |

High elongation; lower yield strength than HDPE |

| Allongement à la rupture | ASTM D638 | ≥ 600% | Excellent flexibility & deformation capacity |

| Résistance à la déchirure | ASTM D1004 | ≥ 125 N | Good anti-tear property |

| Résistance à la perforation | ASTM D4833 | ≥ 160 N | Adequate for ponds & canals |

| Carbon Black Content (black liners) | ASTM D4218 | 2 à 3 % | UV resistance; dispersion per ASTM |

| OIT (Std/HP) | ASTM D3895/D5885 | ≥ 90 min (Std) ≥ 400 min (HP) |

Oxidative aging resistance |

| Résistance aux fissures sous contrainte (NCTL) | ASTM D5397 | ≥ 150 hr | Environmental stress cracking performance |

| Stabilité dimensionnelle | ASTM D1204 | ±2% | Thermal stability |

| Perméabilité | ASTM (comme spécifié) | ≤ 1.0 × 10−13 cm/s | LLDPE impermeable geomembrane |

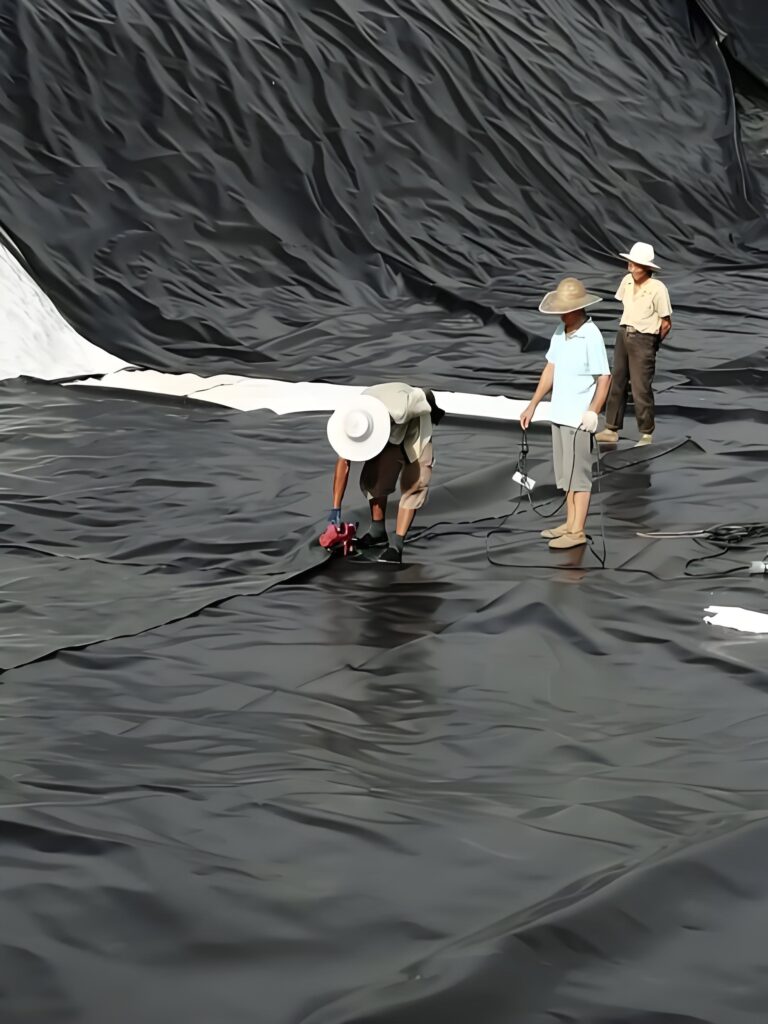

LLDPE Geomembrane Installation, Soudage et CQA

Méthodes de soudage

Hot Wedge Welding (Lower Temperature Range): Due to its high flexibility, LLDPE geomembrane requires lower welding temperatures than HDPE, reducing the risk of over-melting. Ideal for long seams in pond liners and canals.

Extrusion Welding for Detail Works: Commonly used for repairs, patching, pipe penetrations, and corner joints. Filler rod welding ensures secure bonding on irregular areas.

Largeur de chevauchement: Typically 75–100 mm (less than HDPE) because of the material’s high elongation and ease of fusion.

Procédures de contrôle qualité (CQA)

Soudures d'essai: Conducted at the beginning of each shift to confirm correct temperature and speed.

Cartographie des coutures: Visual and mechanical checks to ensure continuous bonding; flexible LLDPE seams are easier to bend and test manually.

Enregistrements: Welding logs document machine type, operator, weather, and parameters for traceability.

Méthodes de test

Non-Destructive Tests (NDT):

Air Pressure Test: Applied to wedge weld channels to verify seam integrity.

Vacuum Box Test: Used for flat seams, detects leakage points effectively.

Destructive Tests (DT):

Peler & Shear Tests: Samples cut at intervals (every 200–300 m²) and tested per ASTM standards.

For LLDPE, elongation during peel tests is higher than HDPE, reflecting its superior flexibility.

Pourquoi choisir Spécialiste WP ?

Over the years, we have established ourselves among trusted LLDPE geomembrane manufacturers and global lldpe geomembrane distributors. Our focus is on delivering reliable liners that meet critical engineering projects.

- Free Samples of LLDPE Geomembrane Sheet

- Assistance de projet experte

- Assurance qualité fiable

- Plus de 10 ans d'expérience en fabrication

- Approvisionnement direct d'usine

Comparison:LLDPE VS LDPE VS HDPE Geomembrane

| Article de comparaison | LDPE Geomembrane | Géomembrane LLDPE | Géomembrane PEHD |

|---|---|---|---|

| Molecular Structure & Crystallinity | Highly branched, lowest crystallinity → very soft and flexible | Short side chains, medium crystallinity → balance of strength and flexibility | Straight chain, highest crystallinity → very rigid and strong |

| Densité | 0.910–0.925 g/cm³ | 0.915–0.925 g/cm³ | 00,941 à 0,965 g/cm³ |

| Résistance à la traction | 10–20 MPa (lowest) | 20–30 MPa (medium) | 30–40 MPa (highest) |

| Élongation | ≥ 800% (highest, extremely flexible) | ≥ 700% (very flexible) | ≤ 500% (lower, more rigid) |

| Résistance à la perforation statique | Weak, not suitable for sharp subgrades | Moderate, suitable for uneven foundations with some protection | Excellent, rigid structure resists sharp puncture |

| Impact Resistance | Excellent, best energy absorption | Good, combines toughness with impact resistance | Average, prone to micro-cracking under dynamic stress |

| Résistance à la déchirure | Highest, strong crack-arrest property | Good, resists tearing in uneven loads | High tensile but cracks can propagate faster |

| Résistance chimique | Good for mild acids/alkalis | Good for general chemical exposure | Excellent, resists strong acids, alkalis, oils, and hazardous chemicals |

| Résistance aux UV | Low, needs stabilizers | Good, with carbon black | Excellent, high carbon black → long-term outdoor exposure |

| Temperature Range | -70℃ to +70℃ | -60℃ to +80℃ | -50℃ to +60℃ |

| Common Thickness | 00,5 à 2,0 mm | 00,5 à 3,0 mm | 00,5 à 3,0 mm |

| Cost Level | Lowest (budget option) | Medium (cost-performance balance) | Highest (premium engineering projects) |

| Applications typiques |

• Light water tanks & indoor liners • Decorative ponds & small landscaping • Temporary anti-seepage covers Recommended when budget is tight and flexibility is key |

• Fish ponds, aquaculture, irrigation canals • Mining site rehabilitation & transport underlayers • Medium waste ponds, dynamic load sites Recommended when you need flexibility + durability balance |

• Municipal landfills, tailings dams • Hazardous waste containment, chemical ponds • Large reservoirs, dam linings, long-term exposure Recommended when long service life & chemical resistance are critical |

| Selection Advice | Choose LDPE if project requires maximum softness and is short-term or light-duty. | Choose LLDPE if project requires adaptability to uneven surfaces et medium service life. | Choose HDPE if project requires highest strength, UV/chemical resistance, et 20+ years durability. |

Les bases de Wholesale LLDPE Geomembrane

Veuillez inclure le type de projet (étang, décharge, exploitation minière, réservoir), l'épaisseur requise, la surface (lisse/texturée), la préférence de taille de rouleau et les conditions de livraison (FOB/CIF + port).

Yes, free LLDPE geomembrane sheet samples are available for evaluation prior to bulk purchase.

Le délai de livraison typique est de 15 à 25 jours pour la production, plus le calendrier d'expédition en fonction du port de destination.

La largeur standard du rouleau pour l'exportation est 5,8 m, optimisé pour le chargement des conteneurs. Des largeurs plus longues telles que 7 à 8 m sont également disponibles, en fonction des conditions réelles de chargement des conteneurs. La longueur du rouleau varie généralement de 50-150 m, ajusté par épaisseur. Des panneaux préfabriqués sur mesure peuvent être fournis si nécessaire.

Poids (g/m²) = Épaisseur (mm) × Densité (g/cm³) × 1000.

For LLDPE geomembrane with density 0.915–0.925 g/cm³ (selon ASTM D792), un revêtement de 1,0 mm pèse environ 915–925 g/m².

La capacité est calculée en fonction de 40HQ ≈ 25 tonnes poids de chargement. Le nombre exact de rouleaux dépend de l’épaisseur et de la largeur du rouleau ; nous calculons en fonction du poids du revêtement par m² et de la limite de poids du conteneur.

La commande minimum recommandée est 5000 m². La géomembrane étant volumineuse et lourde, nous suggérons au moins une Conteneur 20GP pour une expédition efficace. Nous pouvons également vous aider à consolidation avec d'autres marchandises si nécessaire.

Nous sommes un Fabricant chinois de géomembranes, et les expéditions peuvent être organisées à partir de n'importe quel grand port chinois comme Qingdao, Shanghai ou Ningbo.

Prêt à spécifier une géomembrane ?

- Plus de 15 ans d'expertise en usine

- Solutions sur mesure pour vos besoins

- Expédition mondiale & Support logistique

- Une citation transparente et sans obligation

- 100% de confentialité garantie

Vos informations par courrier électronique seront gardées strictement conformes et notre personnel d'entreprise assurera que vos informations privées sont absolument sûres!

Contact

- info@waterproofspecialist.com

Répondre dans les 12 heures!

Veuillez faire attention à l'e-mail avec le suffixe "@ Étanche-épiscial.com".