For any biogas or anaerobic digestion project, the geomembrane liner is more than just a containment barrier—it is the primary vessel for revenue capture. If your liner leaks water, you have an environmental problem; if it leaks gas, you have a direct financial loss.

However, project owners and EPC contractors constantly face a difficult conflict: the absolute need for high gas-tight performance to ensure safety and yield, versus the strict constraints of the project budget.

This article discusses how to balance liner cost and gas-tight performance when selecting geomembranes for biogas digesters. Drawing from my experience supplying materials to projects across Southeast Asia, Africa, and South America, I will break down where you can save money, where you absolutely cannot, and how to choose the right specification for your specific reactor type.

The "Gas-Tight" Equation: Balancing Permeability and Budget

Understanding the trade-off starts with a clear definition. When we talk about optimizing a biogas liner, we are generally looking for the "sweet spot" where the material is thick and dense enough to maximize methane capture, but not so over-engineered that it destroys the project ROIs.

This guide helps you decide:

- Which material properties actually stop gas leaks (it’s not just thickness).

- Why "cheap" liners often lead to massive revenue loss over 10 years.

- Specific recommendations for farm-scale vs. industrial-scale projects.

- How to evaluate cost versus risk in your procurement strategy.

2. What Does "Gas-Tight Performance" Really Mean?

In my interactions with procurement officers, "gas-tight" is often treated as a checkbox. They assume that if it is plastic and waterproof, it must be gas-proof. This is a dangerous oversimplification. In reality, gas-tightness is a system performance metric determined by four distinct factors.

2.1 Material Gas Permeability

At a molecular level, no polymer is perfectly impermeable. Gas molecules can migrate through the microscopic spaces between polymer chains.

- HDPE (High-Density Polyethylene): This is the industry standard for a reason. HDPE has a high crystalline structure (tightly packed molecular chains), which creates a tortuous path for methane molecules ($CH_4$). It acts as a superior barrier compared to lower density materials.

- LLDPE (Linear Low-Density Polyethylene): While LLDPE is more flexible and easier to install, it generally has higher gas permeability than HDPE. In floating covers where flexibility is required, we often have to increase the thickness of LLDPE to achieve the same gas barrier performance as a thinner HDPE.

2.2 Liner Thickness vs. Gas Barrier

There is a misconception that doubling the thickness doubles the gas barrier. While a 2.0mm liner is certainly less permeable than a 1.0mm liner, the relationship is not always linear regarding system leaks.

- The Diminishing Return: Increasing thickness from 0.5mm to 1.0mm provides a massive jump in gas retention. Moving from 2.0mm to 2.5mm offers a much smaller marginal gain in permeability reduction, but a significant increase in material cost.

- The Real Value of Thickness: In biogas, thickness is often more about durability than permeability. A thicker liner (e.g., 1.5mm vs 1.0mm) is more resistant to accidental punctures during installation and stress cracking during operation. A single puncture will release more gas in one hour than molecular permeation will release in a year.

2.3 Welding Quality & Seaming System

I cannot stress this enough: The seam is the bottleneck.

A premium 2.0mm virgin resin HDPE liner with poor welding is far worse than a budget 1.0mm liner with perfect welding.

- In biogas systems, the liner is often under positive pressure. This pressure actively pushes gas against the seams.

- If the welding parameters (temperature, speed, pressure) are not adjusted for site conditions, the weld may peel or suffer from "stress cracking" over time.

- Gas-tight performance is 20% material science and 80% installation discipline.

2.4 Installation & Subgrade Conditions

If the subgrade is uneven, the liner stretches. When HDPE stretches (yields), its thickness decreases, and its permeability increases. Furthermore, stress concentration points are where cracks initiate. You cannot evaluate the "gas-tightness" of a material without considering the surface it sits on.

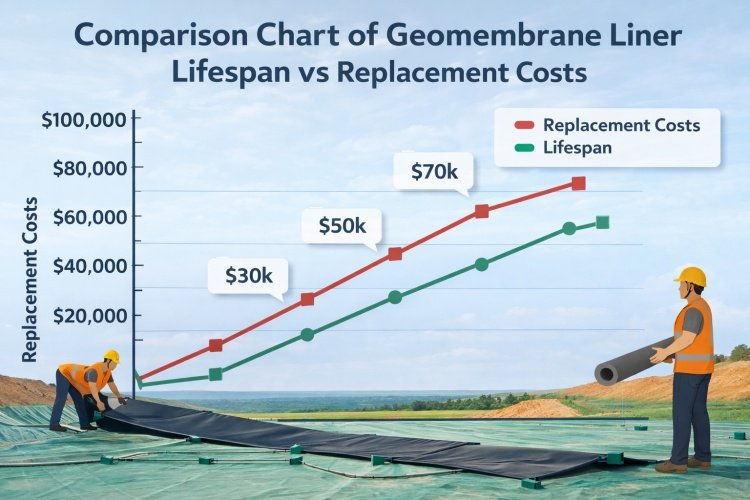

3. Understanding Liner Cost: Why "Cheaper" Often Costs More

When reviewing bids, it is tempting to choose the supplier offering a generic geomembrane at $0.50/sqm less than the competition. However, in the biogas sector, the "cheapest" material often results in the most expensive project.

3.1 Initial Material Cost vs. Life-Cycle Cost

Let’s look at the math of a leak.

- Methane Loss: Methane is lighter than air. If your floating cover has micro-cracks or pinholes, the gas doesn't just sit there; it escapes continuously. If you are generating electricity, every cubic meter of escaped gas is lost kilowatt-hours.

- Odor and Safety: Leaks release Hydrogen Sulfide ($H2S$) and Ammonia. While the cost of the liner is fixed, the cost of neighbor complaints, regulatory fines, and potential explosion risks is unlimited.

- Repair Costs: fixing a leak in a biogas digester is a nightmare. You have to stop the feed, purge the gas, often drain the sludge, and send a technician into a hazardous confined space. The cost of one repair intervention usually exceeds the visible savings of buying a cheaper liner.

3.2 Typical Cost-Driven Mistakes in Biogas Projects

We see specific patterns in failed projects:

- Going Too Thin: Using 0.75mm or 1.0mm HDPE for large-span floating covers to save money. The lack of stiffness leads to excessive wrinkling, and the thin material cannot withstand the UV and thermal stress, leading to cracking within 3–5 years.

- Ignoring Resin Quality: Buying liners made from "recycled" or "mixed" resin. These lack the proper antioxidant packages. Under the chemical attack of the digestate, they become brittle and lose their gas-tight properties rapidly.

- Neglecting Structure: Skipping the geotextile underlay to save a few cents per square meter. The result is stones poking through the liner from below as the sludge weight settles.

3.3 When Cost Reduction Makes Sense—and When It Doesn’t

Cost reduction is not always bad.

- Sensible Savings: Using a thinner liner (e.g., 1.0mm) for a small, temporary storage lagoon that will be decommissioned in 5 years.

- Dangerous Savings: Using a thinner liner for the primary digester of a 2MW power plant intended to run for 20 years.

4. Practical Liner Selection Recommendations by Project Type

Not all digesters are created equal. As a supplier, I advise varying specifications based on the scale and purpose of the project. Here is how we typically advise clients to balance cost and performance.

4.1 Small Farm-Scale Biogas Systems

These are typically low-pressure systems (like plug-flow digesters or small covered lagoons) used for cooking gas or small generators.

- Project Characteristics:

- Limited financing; cost sensitivity is high.

- Low operating pressures.

- Often self-installed by farmers or local general contractors.

- Recommended Approach:

- Material: PEBDL ou Flexible HDPE.

- Thickness: 0.75mm – 1.0mm / 1.5mm.

- Reasoning: Small projects require ease of installation. LLDPE is easier to weld by hand and handles uneven subgrades better. While slightly more permeable, the gas loss is negligible at this scale compared to the ease of ensuring a good seal during manual installation.

- Key Balance: Prioritize installability over absolute zero permeability.

4.2 Industrial Anaerobic Digesters / CSTRs

These are large-scale energy projects or wastewater treatment plants (e.g., palm oil mills, starch factories).

- Project Characteristics:

- High methane generation rates.

- Continuous operation (24/7).

- Professional installation teams available.

- Recommended Approach:

- Material: Premium Virgin HDPE.

- Thickness: 1.5mm – 2.0mm (Bottom) / 2.0mm (Cover).

- Reasoning: The cost of the liner is a tiny fraction of the total plant cost. The priority here is durability et security. A 2.0mm HDPE liner offers superior resistance to UV (for exposed covers) and chemical attack. The lower permeability of HDPE maximizes gas yield.

- Key Balance: Higher upfront material cost is justified by risk mitigation and secured revenue.

4.3 Biogas Projects in Cold Climates

Projects in Russia, Northern China, or Canada face thermal cracking risks.

- Project Characteristics:

- Installation often happens near freezing temperatures.

- Liners become stiff and brittle in winter.

- Recommended Approach:

- Material: PEBDL ou Specialized Low-Temp HDPE.

- Thickness: 1.5mm.

- Reasoning: Standard HDPE can suffer from Environmental Stress Cracking (ESC) if flexed during freezing conditions. LLDPE retains elongation properties in the cold, ensuring the gas seal remains intact even if the ground heaves or the cover moves under snow load.

- Key Balance: Prioritize flexibility to prevent catastrophic brittle failure.

4.4 High Pressure or High Methane Concentration Systems

Systems where gas purification is involved or pressures are higher than minimal water column height.

- Project Characteristics:

- Strict environmental compliance.

- Safety is paramount.

- Recommended Approach:

- Material: Conductive HDPE ou EVOH-Barrier Geomembranes.

- Thickness: >1.5mm.

- Reasoning: For ultra-critical applications, standard HDPE might still permeate too much. Co-extruded barrier films (like EVOH layers) or conductive-backed liners (which allow spark testing for 100% leak detection) provide the ultimate gas tightness.

- Key Balance: Performance is non-negotiable; cost is secondary.

5. How to Balance Cost and Performance: A Practical Decision Framework

If you are negotiating with suppliers and trying to finalize your budget, use this framework to determine where you stand.

| Decision Factor | Low Cost Priority (Economy) | Balanced Approach (Standard) | Performance Priority (Premium) |

|---|---|---|---|

| Typical Project | Small manure pit, temporary storage | Municipal AD, Farm Power Plant (500kW) | Chemical/Industrial Plant, >1MW Power |

| Liner Material | 1.0mm Recycled/Mixed HDPE | 1.5mm Virgin Resin HDPE | 2.0mm+ Virgin HDPE or LLDPE |

| Gas Tight Strategy | Accept minor losses; focus on keeping water in/out | Focus on good welding; minimize permeation | Zero-leak tolerance; Spark testing required |

| Risk Profile | High maintenance risk acceptable | Standard warranty required (5-10 years) | 20-year operational guarantee required |

| Subgrade Prep | Minimal earthworks | Compacted clay/sand cushion | Geotextile cushion + Drainage layer |

To make the final decision, ask yourself:

- What is the cost of downtime? If stopping the process costs \$10,000/day, spend the extra \$20,000 on the thicker, virgin liner now.

- Who is installing it? If you have expert welders, you can use HDPE. If you have unskilled labor, pay extra for LLDPE to ensure the welds actually hold.

- Is the cover exposed? If yes, do not compromise on UV stabilizers (Carbon Black dispersion). A cheap liner will degrade and leak gas in 2 years.

6. The Role of an Experienced Geomembrane Supplier

Many buyers mistakenly view the supplier merely as a factory that ships rolls of black plastic. In reality, a competent supplier acts as a technical partner in the gas-tight system.

À Waterproof Specialist, we realize that supplying the liner is only 50% of the solution. The other 50% is ensuring that the liner fits the project context.

How we support the balance:

- Material Selection: We don't just sell what we have in stock. We analyze your climate and reactor type to recommend High-Crystallinity HDPE (for barrier) or Flexible LLDPE (for cold/moving covers).

- Thickness Optimization: We help calculate whether a 1.5mm liner is sufficient or if a 2.0mm liner is necessary based on your subgrade and pressure requirements.

- Welding Guidance: We provide tailored welding parameters (temperature/speed windows) for our specific resin formulations, ensuring your on-site team creates a homogeneous bond.

- Customization: For complex projects, we can provide custom roll lengths to minimize the number of field seams—directly reducing the risk of leakage and installation cost.

By engaging with the supplier early in the design phase, you can often save money by optimizing the spec rather than over-engineering or under-buying and facing failure later.

7. Risks, Limitations, and When Liners Are Not Enough

It is important to state clearly: A geomembrane liner is not a magic solution. Even the most expensive, gas-tight liner will fail if the surrounding engineering is flawed.

- Gas Pressure Relief: If the system design lacks proper pressure relief valves, gas buildup can overstress even the thickest liner, causing catastrophic rupture.

- Under-Liner Drainage: Biogas generation creates condensation and groundwater issues. Without a proper drainage system under the liner, hydrostatic pressure (whales) can bubble up the liner, stressing seams and causing leaks.

- Mechanical Damage: Agitators and mixers inside the digester are the enemies of liners. If flow patterns drive solids against the liner, abrasion will eventually wear through the gas barrier.

In these scenarios, the solution is not "buy a better liner." The solution is "fix the civil and mechanical design." We always advise clients to view the geomembrane as part of a holistic system.

Conclusion

Achieving gas-tight performance in a biogas digester is not about finding the most expensive material—it is about finding the right material for your specific operational reality.

- Gas-tightness is critical: It is the difference between a profitable power plant and a hazardous waste pit.

- Lowest cost is rarely cheapest: Saving on liner thickness or resin quality usually leads to operational losses that dwarf the initial savings.

- Context is king: A small warm-climate farm needs a different solution than a large cold-climate industrial plant.

Your goal should be to minimize the "Total Cost of Ownership," not just the "Price per Square Meter."

Ready to select the right liner for your biogas project?

Contact us for a technical consultation. We can review your project parameters and provide a geomembrane specification that balances your budget with the strict gas-tight performance your investment requires.