Fournisseur de matériaux géocomposites : solutions intégrées pour le drainage, le renforcement et l'étanchéité

Découvrez comment le géotextile, le géofilet, la géomembrane et la géogrille peuvent être combinés dans des systèmes composites haute performance.

Géomembrane composite (Géomembrane + Géotextile)

Bases de décharge & couvercles, bassins de résidus/étangs industriels, réservoirs et canaux, imperméabilisation de tunnels/sous-sols, drainage/imperméabilisation de jardins sur toit, barrages et digues, autoroutes/aéroports où anti-infiltration renforcé est requis.

Un géosynthétique laminé qui lie une géomembrane imperméable (HDPE/LLDPE/PVC/EVA) avec une ou deux couches de géotextile. La membrane offre imperméabilité, tandis que le géotextile fournit protection mécanique, filtration et séparation— donnant une seule feuille qui s'installe rapidement et fonctionne dans des conditions difficiles.

Principales fonctionnalités & Explications

Anti-infiltration fiable

Le film polymère (généralement HDPE ou LLDPE) forme une barrière continue contre l'eau et les produits chimiques, ce qui le rend adapté aux réservoirs, canaux, bassins de résidus et revêtements de décharges.Haute crevaison & résistance à la déchirure

La ou les couches géotextiles amortissent la membrane pendant la mise en place/le remblayage et répartissent les charges ponctuelles. Cela réduit les dommages causés par l'installation et prolonge la durée de vie, en particulier sur les fondations angulaires.Liaison stable sous charge

Le laminage thermique ou adhésif maintient les couches intégrées, empêchant ainsi le glissement entre le tissu et le film lors du tassement, de la circulation ou du soulèvement hydraulique.Chimique & Durabilité aux UV

La sélection de polymères et les stabilisants antioxydants/UV permettent une exposition et une résistance à long terme aux acides, aux alcalis et aux lixiviats, ce qui est essentiel dans les projets de traitement des déchets et des eaux industrielles.Construction efficace

Les rouleaux larges (3 à 6 m, standard 4 à 6 m) réduisent les coutures. Le côté membrane est compatible avec le soudage standard à coin chaud/air chaud ; les faces géotextiles facilitent la protection et le contact avec le sol.

Structures (par construction)

Un tissu + un film (1F-1M) – Un non-tissé sur une face d’une membrane. Performance équilibrée pour un anti-infiltration général avec une protection de base.

Deux tissus + un film (2F-1M) – Tissus des deux côtés du film. Résistance supérieure à la traction et à la perforation pour la conservation de l'eau et les travaux municipaux.

Un tissu + deux films (1F-2M) ou Multi-tissus/multi-films – Rigidité accrue, redondance des barrières et protection des fondations difficiles ou facteurs de sécurité plus élevés.

Matériaux (par résine membranaire)

PEHD – Résistance chimique/UV la plus élevée ; préféré pour les décharges et les réservoirs exposés.

PEBDL – Meilleure flexibilité et adaptation à l’installation.

PVC – Très flexible; adapté aux fondations inégales, aux zones humides et aux eaux paysagères.

EVA – Excellentes performances à basse température pour les régions froides.

Tissus de base (par type de géotextile)

Non-tissé de fibres discontinues (PP/PET) – Amorti et filtration économiques.

Non-tissé filamentaire (PET/PP) – Résistance à la traction et au fluage plus élevée pour les sites exigeants.

Renfort tissé/tricoté – Ajoute une résistance à la déchirure et à la friction pour les pentes raides ou les charges élevées.

| Configuration | Tissu (g/m²) | Épaisseur du film (mm) | Notes |

|---|---|---|---|

| 1 Tissu + 2 Films | 100-1000 | Chaque film 0,10–1,50 | Construction à double film pour une redondance et une rigidité de barrière plus élevées. |

| 1 Tissu + 1 Film | 100-1000 | 00,10 à 1,50 | Performance équilibrée pour un anti-infiltration général avec protection. |

| 2 Tissus + 1 Film | 80 à 600 (de chaque côté) | 00,20 à 1,50 | Résistance supérieure à la traction et à la perforation ; commun dans les travaux d’eau/municipaux. |

| Multi-tissus / Multi-films | Coutume | Coutume | Construit sur commande pour des fondations et des facteurs de sécurité exigeants. |

* Les valeurs sont des plages typiques et personnalisables (largeur 3 à 6 m, couleurs noir/blanc, packs UV/antioxydant disponibles). Avec un film de polyéthylène stabilisé ≈0,2 mm comme référence, l'expérience sur le terrain indique environ 40 à 50 ans dans des conditions d'eau propre et environ 30 à 40 ans dans des environnements d'eaux usées/lixiviats, répondant aux exigences de service à long terme des barrages/décharges lorsqu'ils sont correctement conçus, soudés et protégés.

Géogrille composite (Géogrille + Géotextile)

Les composites de géogrille sont largement appliqués dans fondations routières et ferroviaires, remblais de murs de soutènement, renforcement du remblai, stabilisation des côtes et des pentes, et projets d'amélioration des sols mous. Ils combinent renforcement et filtration en une seule étape, ce qui les rend très efficaces pour les travaux de génie civil à grande échelle.

Le composite géogrille est un matériau de renforcement haute performance fabriqué en collant ou en cousant une couche géotextile sur une base de géogrille biaxiale ou uniaxiale. Le la géogrille offre une résistance à la traction et un confinement du sol, tandis que le le géotextile assure la filtration et la séparation, formant un système multifonctionnel qui renforce le sol tout en maintenant un bon drainage.

Principales fonctionnalités & Explications

Renforcement & Répartition de la charge – La haute résistance à la traction de la géogrille transfère et répartit efficacement les charges, améliorant ainsi la capacité portante et réduisant la déformation.

Filtration & Séparation – Le géotextile attaché empêche la migration du sol tout en permettant l’écoulement de l’eau, maintenant ainsi l’intégrité du sol de fondation.

Efficacité de construction améliorée – Combiné en un seul produit, il réduit les étapes d’installation par rapport au placement séparé de la grille et du textile.

Haute durabilité & Résistance chimique – Fabriqués à partir de matériaux PP, PET ou HDPE, adaptés à une utilisation à long terme dans les environnements routiers et remblai.

Conception adaptable – Disponible en différentes résistances à la traction (20 à 200 kN/m) et ouvertures de grille pour s'adapter à différentes conditions de sol.

Type principal

Composite géogrille acier-plastique

Renforcé avec des fils d'acier enveloppés de polyéthylène haute densité (HDPE).

Résistance à la traction et au fluage exceptionnelles ; idéal pour les routes et les remblais à forte charge.

Fonctionne bien sous des charges de trafic répétées et des tassements à long terme.

Composite de géogrille biaxiale HDPE

Fabriqué à partir de feuilles de PEHD étirées formant une grille uniforme.

Offre une résistance équilibrée dans les deux sens, une rigidité élevée et une résistance à la dégradation chimique et biologique.

Couramment utilisé dans les plates-formes routières, les aires de stationnement et le renforcement des fondations.

Composite de géogrille en polyester tricoté en chaîne

Construit à partir de fils PET haute ténacité enduits de bitume ou de PVC, liés par un géotextile.

Offre une excellente résistance à la traction, un faible allongement et une flexibilité pour s'adapter aux surfaces de sol inégales.

Convient aux talus, aux murs de soutènement et au renforcement des sols meubles.

Composite de géogrille en fibre de verre

Composé de brins de fibres de verre résistants aux alcalis enrobés de bitume ou de résine polymère, associés à un géotextile non tissé.

Il offre un module de traction supérieur, une stabilité dimensionnelle et une excellente résistance thermique, réduisant efficacement les fissures réfléchissantes dans les chaussées en asphalte.

Principalement appliqué dans le renforcement de la surface des routes, les revêtements d'asphalte et les projets de réhabilitation des autoroutes.

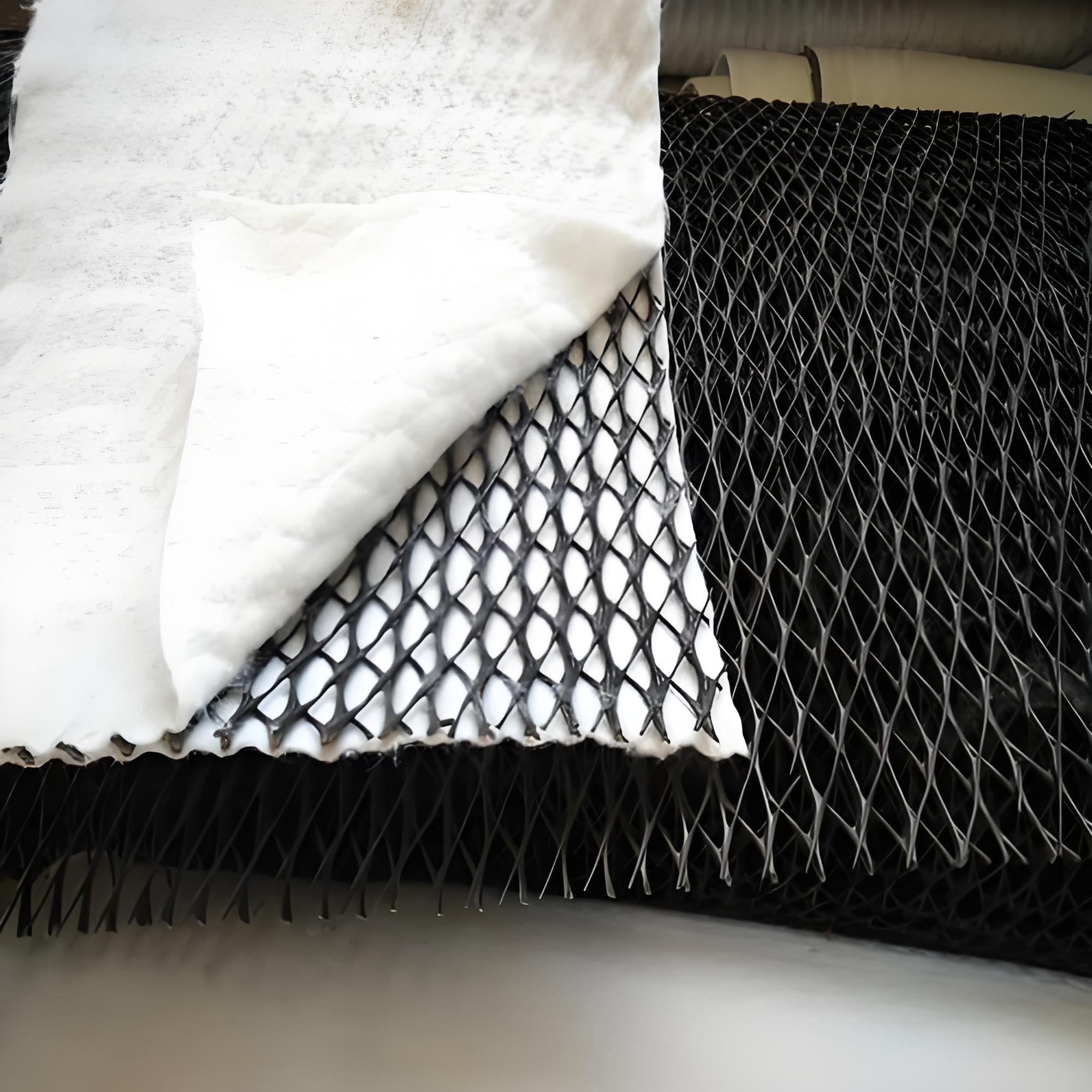

Géonet composite (Géonet + Géotextile)

Les géonets composites tridimensionnels sont largement utilisés dans systèmes de drainage des décharges et de collecte des lixiviats, drainage du sol de fondation des autoroutes et des voies ferrées, imperméabilisation de tunnels et de sous-sols, et couches de drainage des murs de soutènement ou des pentes.

Le géonet composite tridimensionnel est une nouvelle génération de géosynthétique de drainage composé d'un noyau géonet à trois couches lié avec géotextiles non tissés aiguilletés des deux côtés.

Le noyau du géonet se compose d'un nervure verticale épaisse et deux côtes inclinées en haut et en bas, formant un canal de drainage à haut débit qui peut rapidement évacuer les eaux souterraines des fondations ou des structures de retenue.

La structure maintient la stabilité des vides sous de lourdes charges, bloque l'eau capillaire et fournit drainage, isolation et renforcement fonctions dans un seul produit.

Principales fonctionnalités & Explications

Excellente capacité de drainage – Les canaux multidirectionnels permettent une évacuation rapide de l’eau, même sous des charges de compression à long terme dépassant 2 000 kPa.

Haute résistance & Résistance au cisaillement – La structure de base triplanaire assure la stabilité et résiste à la déformation sous des contraintes élevées.

Stabilité du débit à long terme – Les couches géotextiles protègent le noyau de l’intrusion du sol, maintenant une perméabilité constante.

Haute résistance à la compression – Résiste à des charges beaucoup plus élevées que les géofilets conventionnels tout en conservant plus de 60 % d’épaisseur après 10 000 heures d’essai de fluage à 1 200 kPa.

Filtration intégrée & Séparation – Les géotextiles non tissés évitent le colmatage des sols tout en permettant l’écoulement de l’eau.

Caractéristiques de performances

À 720 kPa charger et pente de 2 %, la perméabilité est 2500 m/jour, débit 13 l/min/min.

Sous 1 200 kPa charger pour 10 000 heures, conserve > 60% d'épaisseur.

Noyau Geonet : noir de carbone ≥ 2%, densité 0,94 g/cm³, traction ≥ 36,5 kN/m, indice de fusion 1,0 g/10 min, épaisseur 7,6 mm.

Géotextile non tissé : ouverture apparente 0,18 mm, perméabilité à l'eau 0,2 cm/s, crevaison 580 N, déchirure trapézoïdale 356 N, saisir la traction 900 N, éclatement 2750 kPa.

| Article | Valeur typique |

|---|---|

| Masse composite par unité de surface | ≥ 1400 g/m² |

| Masse géotextile par unité de surface | ≥ 200 g/m² |

| Épaisseur du composite | ≥ 7,0 millimètres |

| Épaisseur du noyau | ≥ 5,0 millimètres |

| Résistance à la traction longitudinale | ≥ 18 kN/m |

| Résistance à la traction transversale | ≥ 15 kN/m |

| Résistance à la traction du noyau (dans les deux sens) | ≥ 15 kN/m |

| Résistance au pelage (liaison âme-tissu) | ≥ 0,3 kN/m |

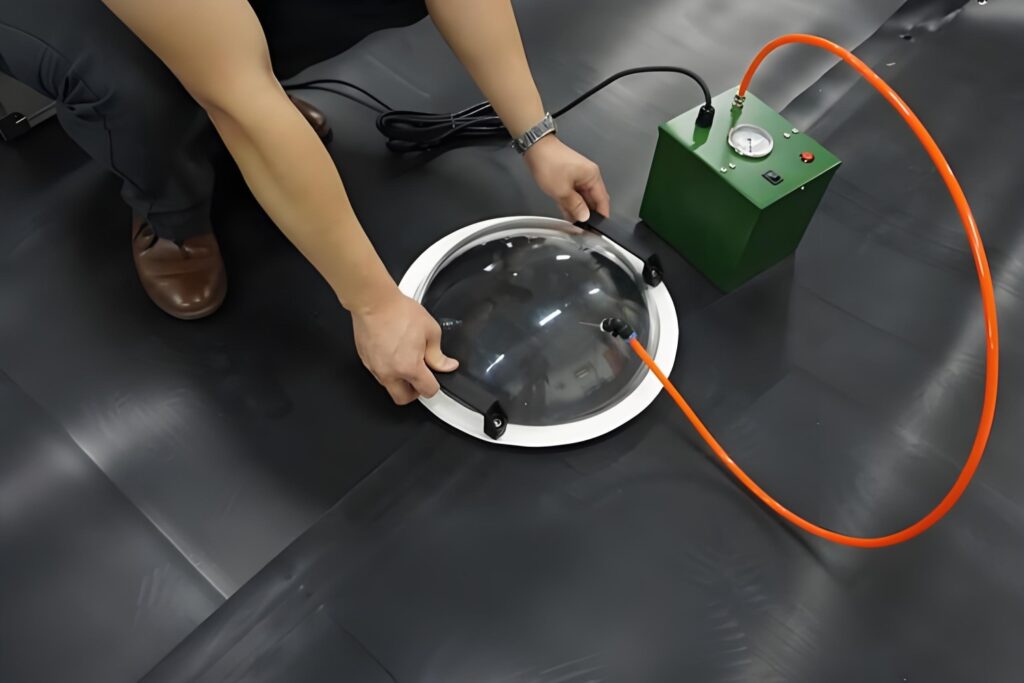

Normes & Contrôle de qualité

Notre Géonets composites tridimensionnels sont fabriqués et testés en stricte conformité avec ASTM et ISO normes pour garantir les performances de drainage à long terme et la stabilité structurelle.

Chaque produit est fabriqué dans des conditions contrôlées pour maintenir une cohérence épaisseur du noyau, force de liaison, et adhésion géotextile qualité.

La portée des tests comprend résistance à la traction, résistance au pelage, fluage compressif, capacité de débit, et perméabilité sous charge, suivant les méthodes ASTM D4716, D5321, D638, et D6243.

Une inspection complète est effectuée pour densité centrale, masse géotextile par unité de surface, intégrité de la liaison, et stabilité dimensionnelle avant expédition pour garantir des performances fiables et constantes.

Si votre projet nécessite le respect de règles spécifiques normes internationales ou nationales, Spécialiste WP peut personnaliser les deux paramètres de production et protocoles de test selon les exigences de conception.

Tests, vérifications et audits d'usine (ASTM / ISO / Intertek) sont toujours les bienvenus pour garantir la transparence et l’assurance qualité de chaque lot fourni.

Pourquoi Travail Avec nous

Contrôle qualité stable avec des délais de livraison fiables dans le monde entier.

Rapports de tests tiers et enregistrements d'assurance qualité traçables inclus.

Conseils de conception, assistance sur site ou à distance et service après-vente.

Prêt à spécifier un géocomposite ?

- Plus de 15 ans d'expertise en usine

- Solutions sur mesure pour vos besoins

- Expédition mondiale & Support logistique

- Une citation transparente et sans obligation

- 100% Confidentialité Garantie

Vos informations de courrier électronique resteront strictement confidentielles et notre personnel commercial veillera à ce que vos informations privées soient absolument en sécurité !

Contact

- info@waterproofspecialist.com

Répondre dans les 12 heures!

Veuillez faire attention à l'e-mail avec le suffixe "@ Étanche-épiscial.com".