When you build infrastructure, you expect it to last for decades. But soil erosion, heavy loads, and harsh weather can cause premature failure, leading to costly repairs and safety risks. Geocells offer a powerful solution, but their long-term success isn't guaranteed.

This guide explores the critical factors that determine the service life of geocells. We will cover how material quality, engineering design, installation practices, and environmental conditions all play a role in ensuring your soil stabilization project delivers durable, lasting performance for decades to come.

1. Material Quality and Manufacturing Standards That Influence Durability

The service life of a geocell system begins with the quality of the raw material. At its core, a geocell is a polymer product, and its longevity is directly tied to the resin used in its manufacturing.

The most significant factor is the use of 100% virgin High-Density Polyethylene (HDPE) resin. Geocells made from virgin HDPE exhibit superior Environmental Stress Crack Resistance (ESCR), which is crucial for maintaining structural integrity under long-term load and environmental exposure. In contrast, products made with recycled materials can contain impurities that compromise weld strength and accelerate degradation. We've seen data showing recycled geocells losing 50% of their properties in half the time it takes for virgin HDPE to lose just 10%.

Key material properties we always verify are:

- UV Stabilization: For any application with potential sun exposure, the HDPE must contain 2.5% to 3.5% finely dispersed carbon black and specialized additives like Hindered Amine Light Stabilizers (HALS). This prevents the polymer chains from breaking down under UV radiation.

- Welding Strength: The seams where the cell walls are joined are potential weak points. We use ultrasonic double-welding techniques that create a molecular bond, ensuring the seam is often stronger than the cell wall itself. This prevents junction failure under thermal stress or load.

2. How Engineering Applications Impact Geocell Longevity

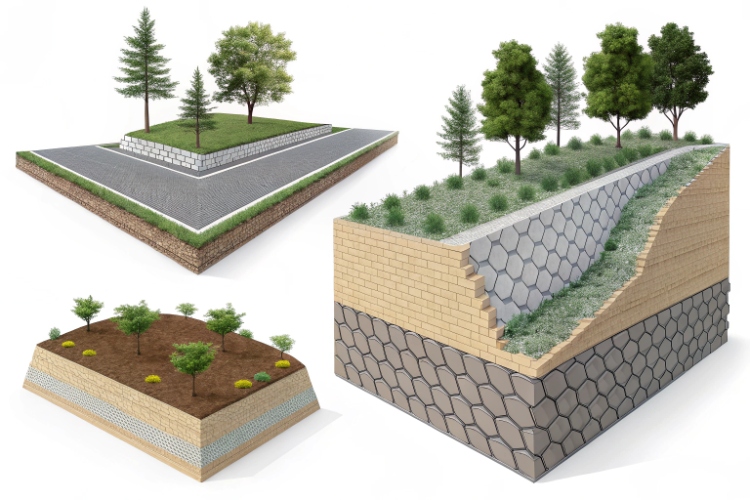

A geocell's service life also depends heavily on what you ask it to do. Different applications subject the geocell to different types of stress, so its design and material must be matched to the task.

- Road Bases: In this application, the geocell is buried and protected from UV light, but it faces millions of repeated load cycles from traffic. The key to longevity here is creep resistance and high junction strength to maintain confinement of the aggregate fill, preventing rutting over time.

- Slope Protection: Here, the geocell’s primary role is to resist erosion from rainfall and gravity. While loads may be static, the geocell is often more exposed to UV radiation and thermal cycling (expansion and contraction). A highly UV-stabilized material is essential for a long service life.

- Retaining Walls: Geocells in retaining walls are under constant tensile stress from the retained earth. Long-term creep performance is critical. If the material stretches or deforms over time, the wall will lose its structural integrity.

- Channel Linings: In channels, the geocell must withstand hydraulic shear forces from flowing water in addition to potential UV and chemical exposure. A robust design with secure anchoring is necessary to prevent uplift and ensure long-term stability.

3. Effect of Construction Quality on Long-Term Geocell Performance

You can have the best geocell material in the world, but if it's installed poorly, it will not perform as designed. We estimate that proper installation can extend the effective service life of a geocell system by 20–40%.

Préparation du sol de fondation

The foundation is everything. The subgrade must be smooth, properly graded, and compacted to at least 95% Proctor density. Any sharp rocks, organic material, or soft spots must be removed. We typically recommend laying a nonwoven geotextile (300–500 g/m²) as a separation layer between the subgrade and the geocell to prevent fill material from migrating.

Backfill Selection and Compaction

The infill material works together with the geocell to create a composite system. The fill must be of the specified quality (e.g., granular aggregate for load support) and must be compacted in layers within the cells. Incomplete compaction leaves voids, which leads to settlement and loss of confinement, dramatically shortening the system's functional life.

Seam Integrity and Anchoring

Panels of geocells must be securely connected, and the entire system must be anchored correctly, especially on slopes. Poor connections or inadequate anchoring can lead to sections pulling apart or sliding, causing a progressive failure of the entire installation.

4. Environmental and Loading Conditions Affecting Service Life

A geocell must be robust enough to withstand the specific environmental challenges of the project site for its entire design life.

Sunlight is a major factor. As mentioned, UV radiation degrades polymers. Any exposed geocell must have a top-tier UV stabilization package. Buried applications, like road bases, are naturally protected and thus have a much longer potential material lifespan.

Temperature extremes also play a huge role. In cold climates, freeze-thaw cycles can destroy traditional road materials. High-quality HDPE geocells excel here, remaining flexible at temperatures as low as -45°C (-50°F). This allows them to accommodate ground movement without cracking. In hot climates, thermal expansion and contraction must be accounted for in the design. A geocell can move 25–50 mm per 100 meters with a 40°C temperature swing, and this movement must be managed to avoid stressing seams.

Finally, chemical exposure must be considered. Standard HDPE offers excellent resistance to most acids, bases, and salts (from pH 1.5 to 12+), making it ideal for most soil conditions. However, for sites with industrial contamination or specific chemicals, a material compatibility assessment is essential.

5. Selecting the Right Geocell Type for Different Site Conditions

Not all geocells are the same. The surface texture and structure of the cell wall are engineered for specific functions. Choosing the right type is key to maximizing performance and longevity.

| Geocell Type | Primary Benefit | Best For Applications Such As... |

|---|---|---|

| Smooth | Low friction with infill material. | Slopes and channels where smooth water flow is desired. |

| Textured | Increased friction with infill. | Load support (road bases) and steep slopes where enhanced soil-to-cell wall friction is needed to hold infill. |

| Perforated | Allows for lateral drainage and root lock-in. | Vegetated slopes, retaining walls, and any application requiring horizontal water drainage through the cells. |

| Renforcé | High-tenacity strips integrated for superior tensile strength. | Very steep slopes, retaining walls, and heavy-duty load support where long-term creep resistance is critical. |

For most standard soil stabilization projects, a textured and perforated geocell offers the best combination of infill confinement, drainage, and flexibility.

6. Typical Service Life Expectations and Testing Standards

With high-quality material and proper installation, what kind of service life can you expect? For buried applications like road bases, an HDPE geocell system is designed to last 50 to 75 years, and potentially longer. In fact, installations by the U.S. Army Corps of Engineers from the early 1990s are still performing perfectly after more than 30 years.

To ensure this longevity, products must be rigorously tested against established industry standards. As a supplier, we ensure our geocells meet or exceed protocols from:

- ASTM International: Provides standards for testing material properties like tensile strength, carbon black content, and ESCR.

- ISO (International Organization for Standardization): Sets global benchmarks for quality management systems in manufacturing.

- GRI (Geosynthetics Research Institute): Establishes specific test methods and standard specifications for geosynthetic products, including geocells.

Adherence to these standards is your assurance that the material's properties have been independently verified.

7. Design and Maintenance Practices to Maximize Geocell Longevity

Achieving a multi-decade service life requires a holistic approach that combines smart design with proactive maintenance.

First, the design must be optimized for the site conditions. This means selecting the right geocell type and cell depth, planning for thermal expansion, and designing a robust anchoring system. Don't over-specify, but never under-specify for critical, long-term infrastructure.

Second, quality must be enforced during installation. This is the most critical phase for ensuring long-term performance. A well-documented quality assurance plan that covers subgrade approval, material handling, and compaction testing is non-negotiable.

Finally, while geocell systems are often considered "maintenance-free," a preventive maintenance plan can significantly extend their life. This includes ensuring drainage systems remain clear to prevent waterlogging, promptly repairing any localized mechanical damage, and periodically inspecting exposed areas for any signs of wear or distress.

Conclusion

The service life of a geocell is not a single number but a result of interconnected factors: the quality of the polymer, the demands of the application, the precision of the installation, and the harshness of the environment. By making informed choices at every stage—from material specification to construction and maintenance—you can ensure your geocell system provides reliable soil stabilization for a half-century or more.