Geocell Ground Grid Manufacturer & Global Supplier

Engineered geocell panels for reliable soil stabilization, erosion control, and load support in road base, slope, and retaining wall applications.

High Load-Bearing Capacity

Excellent contrôle de l'érosion

Quick & Easy Installation

Apprenez à connaître Géocell

A geocell is a three-dimensional honeycomb-like HDPE grid used to confine soil, gravel, or sand. It enhances ground stability, prevents erosion, and distributes loads evenly in construction and landscaping projects.

Geocells are used for soil stabilization, erosion control, slope protection, and road base reinforcement. They are ideal for driveways, retaining walls, parking lots, embankments, and mining haul roads.

Geocells are typically made from HDPE (Polyéthylène Haute Densité) ou PP (Polypropylene).

HDPE offers superior flexibility and chemical resistance, while PP provides higher stiffness and temperature resistance—both deliver strong and durable soil confinement.

High-quality HDPE or PP geocells can last more than 50 years under normal environmental conditions. They resist UV radiation, oxidation, and chemical corrosion, ensuring long-term ground stability and performance.

Geocells can be filled with soil, sand, crushed stone, gravel, or recycled materials depending on the project type. The filled cells form a stable and load-bearing base for roads, slopes, and retaining structures.

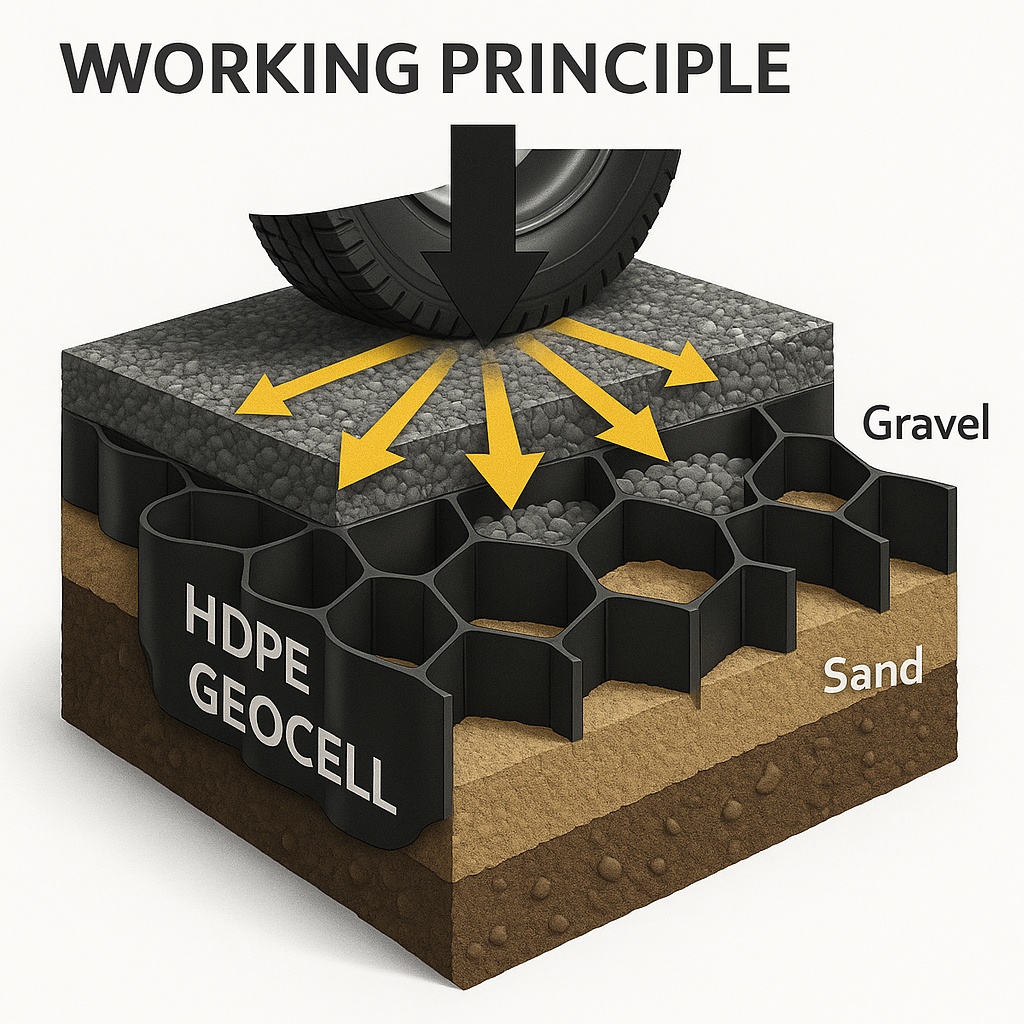

Géocell Principe de fonctionnement

Geocell Structure:

Geocell is a three-dimensional honeycomb structure made from HDPE or PP strips welded together. When expanded on-site, it forms interconnected cells that can be filled with soil, gravel, or sand. The structure confines and stabilizes the infill material, creating a rigid yet flexible base layer for load support.

Load Distribution Mechanism:

When external loads—such as vehicle wheels—act on the surface, the stress is transferred vertically and laterally through the cell walls. This three-dimensional confinement restricts the lateral movement of soil and transforms vertical pressure into a wider, evenly distributed load, reducing rutting and settlement.

Soil Confinement Principle:

Without confinement, the loaded soil forms an active zone that compresses downward and a passive zone that bulges upward, leading to instability and surface deformation. Geocells prevent this by locking the infill material within each cell, greatly enhancing shear strength and overall bearing capacity.

Engineering Benefits:

This cellular confinement system significantly improves ground performance on weak subgrades. It increases load-bearing capacity, minimizes deformation, and provides long-term stability for roads, slopes, retaining walls, and erosion control applications.

Classification et modèles de Géocell

HDPE and PP geocells are available in smooth, textured, and perforated forms. Each type offers different load-bearing and erosion-control performance to suit various civil engineering applications.

| Type | Structure / Description | Principales fonctionnalités | Applications typiques |

|---|---|---|---|

| HDPE – Smooth (Non-Perforated) | High-density polyethylene strips ultrasonically welded into a honeycomb grid; smooth cell walls, no holes. | Easy expansion and placement; good chemical/UV resistance; economical for general base reinforcement. | Temporary/haul roads, construction access, laydown yards, driveway base. |

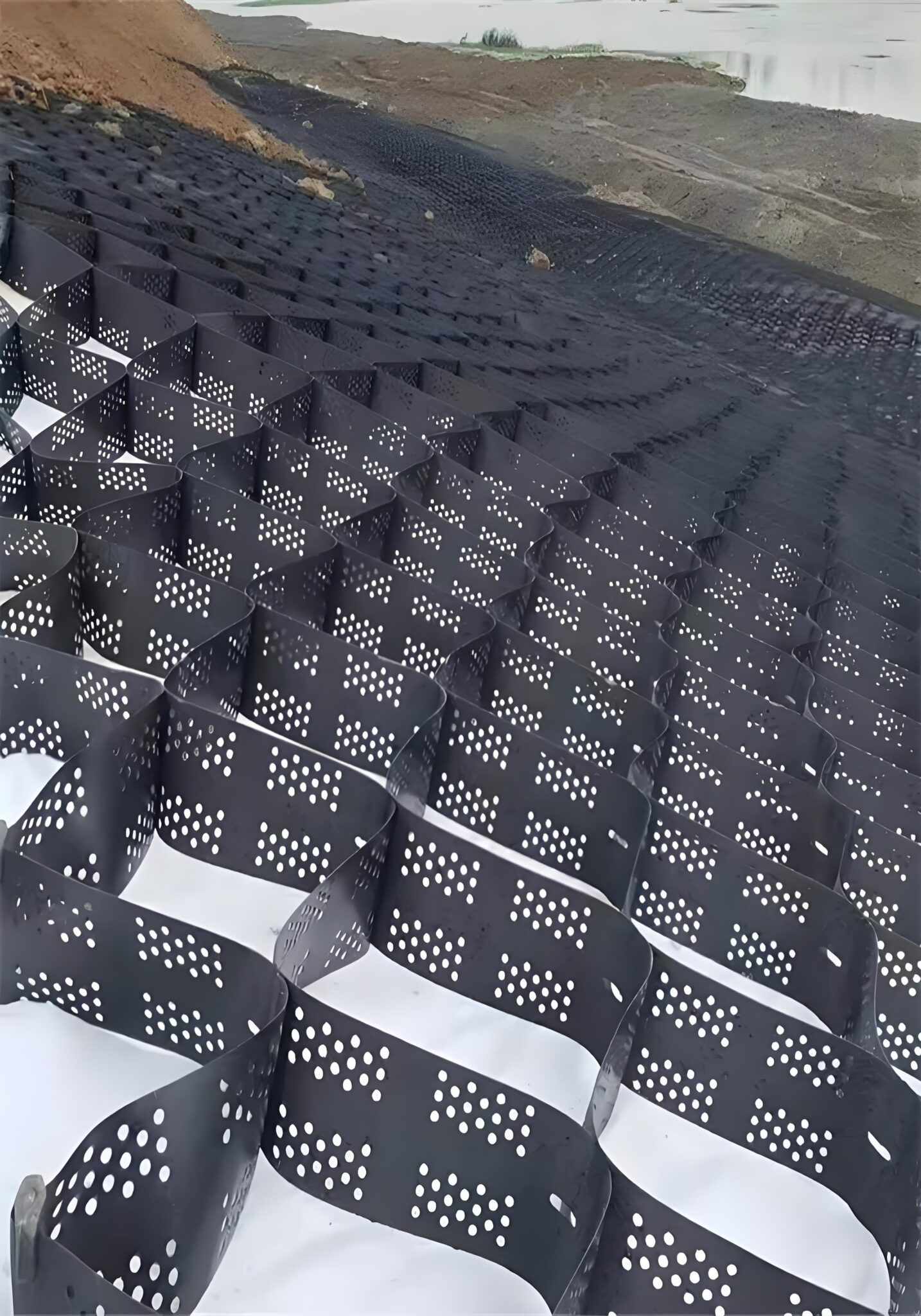

| HDPE – Textured | Same as smooth HDPE but with textured (roughened) cell walls to increase interface friction with infill. | Higher friction & shear resistance; improved slope stability; reduced sliding risk. | Slope protection, embankments, railway/road shoulders, berm faces. |

| HDPE – Perforated | HDPE cells with engineered drainage perforations along the walls to relieve pore water pressure. | Better drainage & weight reduction; supports vegetation growth; enhanced erosion control. | Eco-slopes, channels, riverbanks, vegetated retaining facings. |

| PP – Smooth (Non-Perforated) | Polypropylene cells with smooth walls; higher stiffness compared with HDPE at the same thickness. | Higher modulus & temperature resistance; good dimensional stability under heavy loads. | Heavy-duty yards, industrial floors, high-temperature regions, port storage. |

| PP – Textured | Textured PP cell walls provide strong interlock with aggregates and compacted soils. | Excellent shear performance; reduced lateral spread; durable under cyclic loading. | Steep slopes, reinforced embankments, haul roads on weak subgrades. |

| PP – Perforated | Perforated PP geocell enabling rapid drainage and root penetration in bio-engineered systems. | Efficient water relief; lighter panels; supports vegetation & erosion control. | Green slopes, bioswales, vegetated retaining walls, channel lining. |

Customization Options of HDPE Geocell

Different projects require different geocell configurations.

We offers a full range of HDPE geocell customization options including sheet thickness, weld spacing (cell size), cell height, and color choices.The table below summarizes key parameters and their recommended applications to help you select the most efficient geocell ground grid for road base, slope protection, and erosion control projects.

| Customization Option | Available Specs | Recommended Use / Technical Notes |

|---|---|---|

| Sheet Thickness (HDPE / PP Cell Wall) |

1.0 mm

1.2 mm

1.5 mm

*Other gauges available upon request

|

1.0 mm: Ideal for light-duty projects such as landscaping and slope protection where cost efficiency matters. 1.2 mm: Standard thickness for most geocell road base, driveway, and parking lot reinforcement projects. 1.5 mm: Recommended for heavy-duty haul roads, mining pads, and long-term applications requiring high stiffness and durability. |

| Weld Spacing / Cell Size (expanded cell dimension) |

≈ 320 mm ≈ 356 mm ≈ 445–500 mm |

320 mm (small cell): Provides higher confinement, suitable for fine-grained soil, steep slopes, and curved areas. 356 mm (standard cell): The most common configuration for geocell ground grid and driveway stabilization, balancing strength and economy. 445–500 mm (large cell): Speeds up installation, ideal for coarse aggregate fill, channels, and large erosion control zones. |

| Cell Height | 50 mm 75 mm 100 mm 150 mm 200 mm |

50–75 mm: For slope protection, landscaping, and light-load areas where soil erosion control is needed. 100–150 mm: Universal height range for most road, driveway, and parking lot base reinforcement. 200 mm: Used on weak subgrades or heavy-load applications such as mining, ports, and industrial yards. |

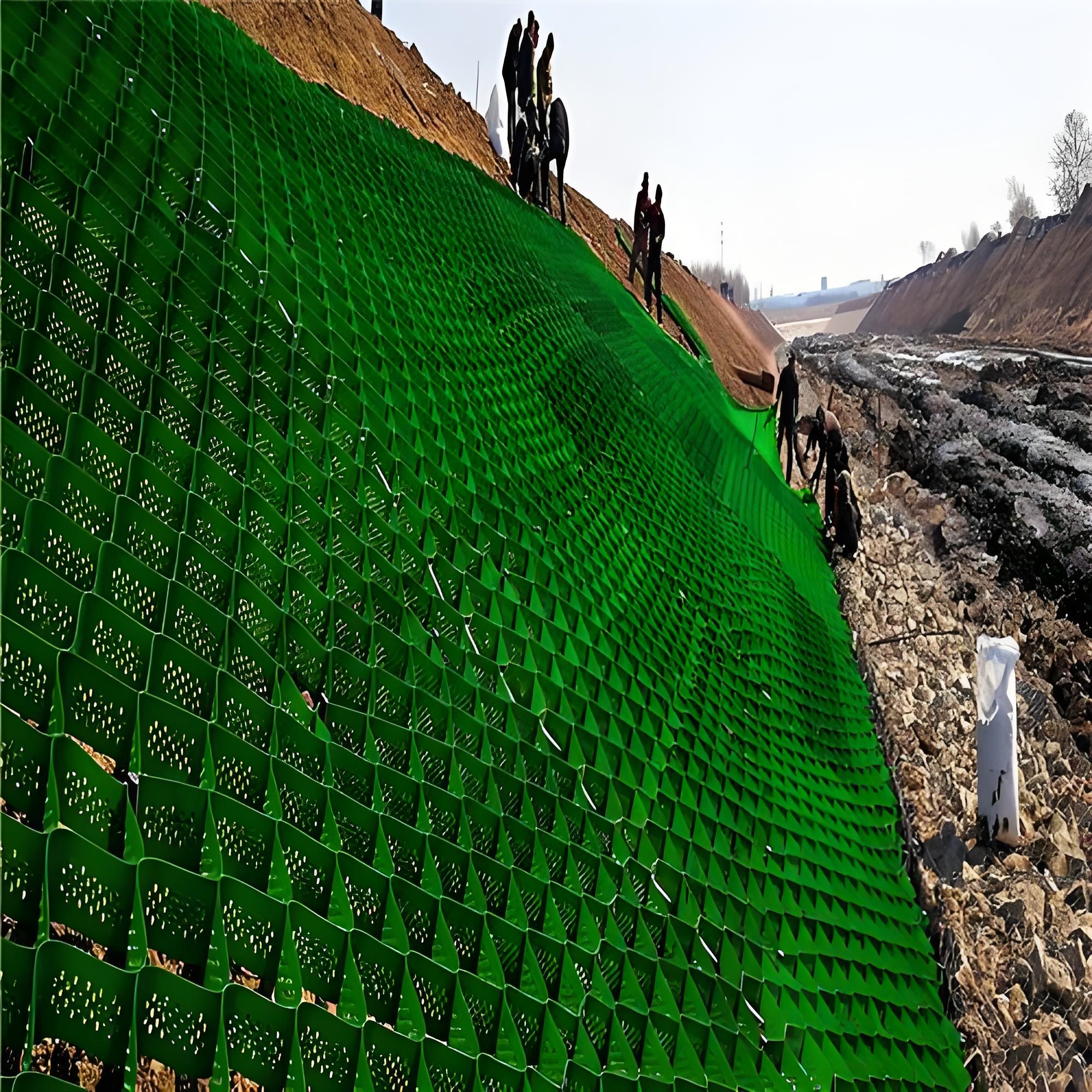

| Color |

Black (standard)

Green

Yellow

*Custom colors available for OEM projects

|

Black: Standard color with best UV resistance and long service life. Green: Perfect for geocell slope protection and vegetated surfaces requiring aesthetic integration. Yellow: Improves visibility during installation and temporary construction zones. |

Typical Application Scenarios for Géocell

Road Base Reinforcement

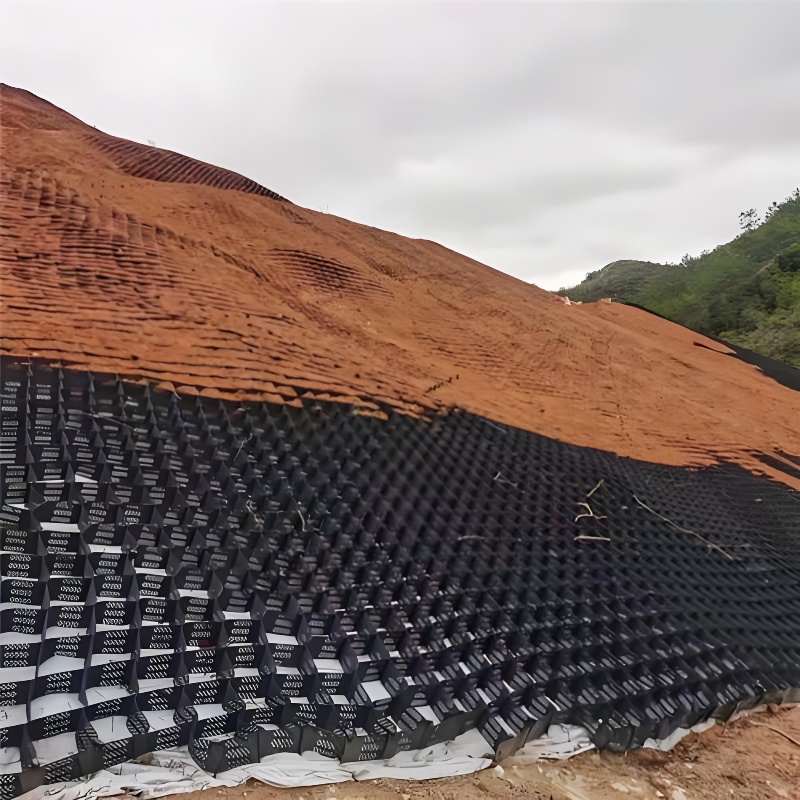

Slope Protection & Erosion Control

Retaining Wall & Embankment Reinforcement

Channel & Riverbank Protection

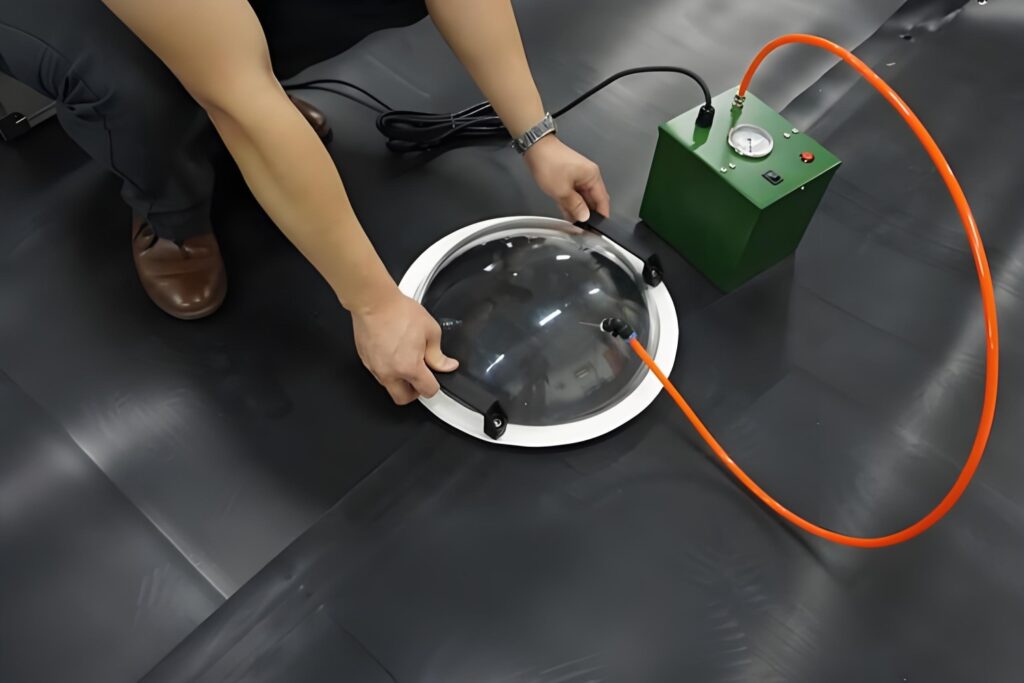

Geocell Testing Standards & Performance Data Sheet

| Test Item | Purpose / Description | ASTM | ISO | Typical Range / Notes |

|---|---|---|---|---|

| Material Density (HDPE / PP) | Verify base polymer identity and stability. | D1505 | 1183-1 | HDPE 0.935–0.960 g/cm³PP 0.90–0.91 g/cm³ |

| Melt Flow Rate (MFR) | Processing consistency & weldability of strips. | D1238 | 1133-1 | Factory spec (e.g., 0.3–1.0 g/10 min) |

| Tensile Strength of Cell Strip | Tensile properties of individual strips. | D638 | 527-3 | HDPE ≥ 22 MPa; PP ≥ 28 MPa |

| Weld / Seam Peel Strength | Bonding strength at ultrasonic welds. | D4437 | 10321 | ≥ 100 N/10 mm |

| Carbon Black Content (UV) | UV protection level for outdoor service. | D4218 | 6964 | 1.5–2.5 % (HDPE) |

| Temps d'induction oxydative (OIT) | Antioxidant stability against thermo-oxidation. | D3895 | 11357-6 | ≥ 100 min @ 200 °C |

| ESCR (Stress Crack Resistance) | Resistance to cracking under stress/chemicals. | D1693 | 16770 | Pass (no cracks within set time) |

| Creep / Long-term Deformation | Predict long-term strain of cellular structure. | D6992 | 13431 | Strain ≤ 2% @ specified time/load |

| Stabilité dimensionnelle | Thermal shrinkage of strips after heating. | D1204 | 294-4 | ≤ 2% change |

Avantages et fonctionnalités clés of Geocell

Geocells are collapsible for compact transport and can be easily expanded into a 3D honeycomb structure during installation.

Once filled with soil, gravel, or concrete, they form a stable load-bearing layer with strong lateral confinement and rigidity.

Made from HDPE or PP, the geocell offers excellent resistance to abrasion, oxidation, UV degradation, and chemical corrosion.

It performs reliably in a wide range of soil types, including soft

The cellular confinement structure prevents lateral soil movement, enhances subgrade bearing capacity, and distributes traffic loads evenly.

This reduces rutting, settlement, and deformation under repeated loading.

Cell height and weld spacing can be customized (typically 50–200 mm height, 320–500 mm cell size) to meet different engineering requirements such as road bases, slopes, and retaining structures.

The foldable design reduces transport volume and allows rapid on-site deployment.

Interlocking and connection systems make construction fast, safe, and cost-effective.

When loads act on the subgrade, the geocell confines the infill and transforms vertical pressure into a three-dimensional stress network.

This confinement prevents lateral displacement of soil and improves the overall bearing capacity and stability of the ground structure.

Géocell Installation Method

Ground grid system.

The following steps summarize standard procedures for road base reinforcement, slope protection, and erosion control projects.

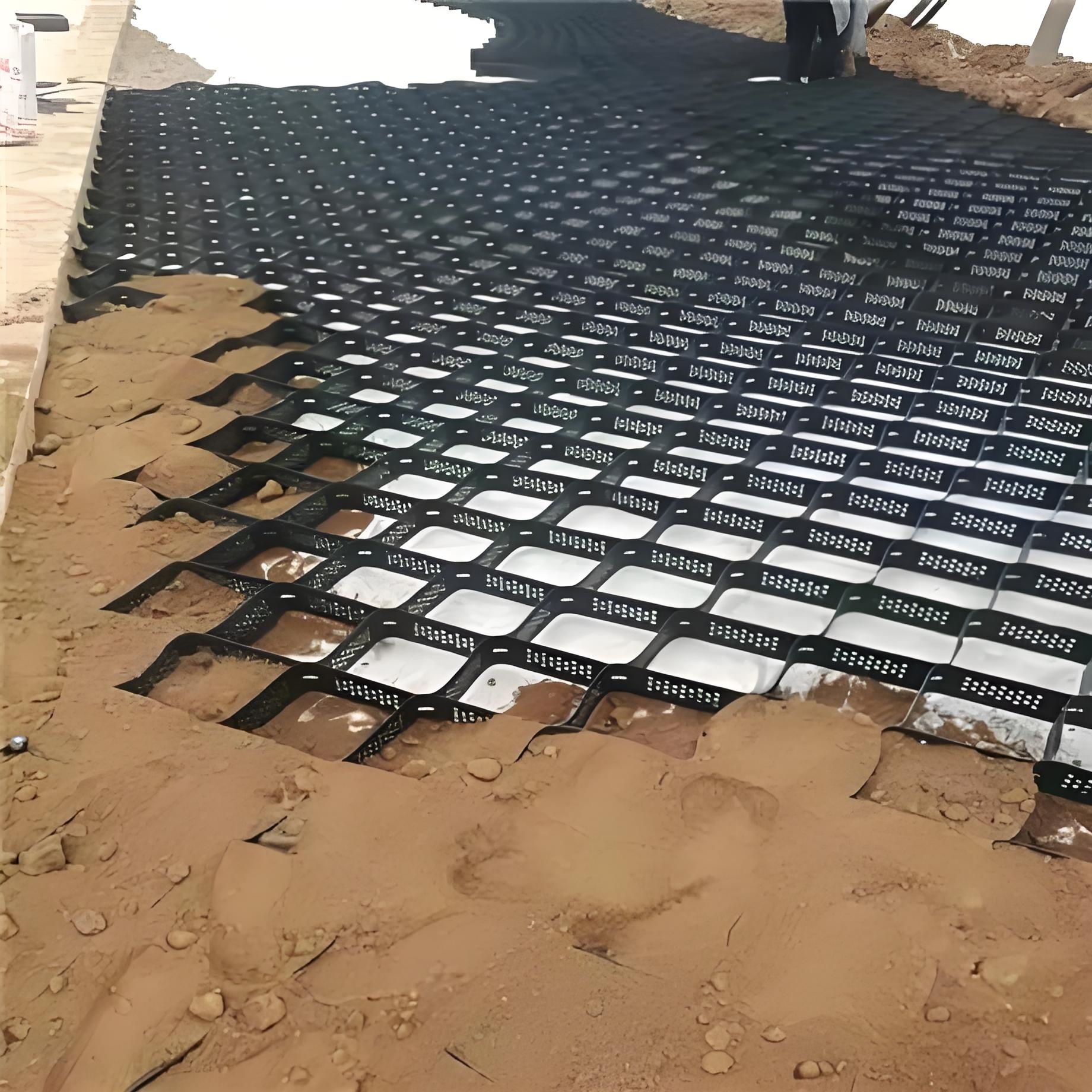

Subgrade preparation

Make sure the foundation is level, compacted, and free from sharp stones, roots, or debris that might damage the cell walls.

The subgrade should reach at least 95% compaction. For slope work, keep the gradient within 1:2.5 for stability.

Geocell expansion and placement

Expand the folded geocell into a honeycomb shape on site and align it according to the project layout.

Provide a 100–150 mm overlap between adjacent panels, and use temporary pins or rebar anchors to keep the grid in place during infill.

Fixing and anchorage

For slopes, secure the geocell with U-shaped anchors or steel stakes at the crest and toe.

Anchor spacing is usually 1.0–2.0 m depending on slope angle and cell height.

For flat areas, adjacent panels can be joined with clips, staples, or screws.

Infill placement

Gradually fill the geocell with the specified material—soil, gravel, or concrete—based on the application.

Soil or sand: for vegetated slope protection.

Gravel or crushed stone: for driveways and road bases.

Concrete: for permanent erosion or channel protection.

Avoid overfilling by more than 20 mm above the cell wall.

Compaction and surface finishing

Compact the infill material layer by layer with a light roller or plate compactor until the surface is level and stable.

Ensure full contact between the infill and geocell walls before paving or seeding.

Panel connection

Connect adjacent panels using rivets, staples, or plastic clips through pre-punched holes to prevent shifting during compaction.

Protection and maintenance

For exposed slopes, apply a vegetation cover or geotextile mat to reduce UV exposure.

Inspect anchors and joints regularly, especially after heavy rain or during early settlement.

Pourquoi choisir Spécialiste WP ?

Au fil des années, Spécialiste WP has become one of China’s reliable manufacturers and global exporters of HDPE Geocell (Cellular Confinement System) products.

Our factory provides high-strength geocell panels engineered for road base reinforcement, slope stabilization, load support, and erosion control applications worldwide.

Nous sommes spécialisés dans la production engineered geocells with excellent tensile strength, UV resistance, and long-term durability — fully compliant with ASTM D1505, D638, D4218, and ISO 527-3 testing standards.

Tous les produits sont soutenus par factory-direct pricing, professional technical guidance, et customized design options to fit different soil and loading conditions.

- Free Samples of HDPE Geocell

- Assistance de projet experte

- Assurance qualité fiable

- Plus de 10 ans d'expérience en fabrication

- Approvisionnement direct d'usine

Normes & Contrôle de qualité

Tous HDPE and PP Geocells are manufactured and tested in accordance with internationally recognized standards such as ASTM, ISO, and GRI.

Each batch is produced under controlled conditions to ensure consistent polymer quality, weld integrity, and overall mechanical stability.

Testing scope covers material density, melt flow rate (MFR), tensile strength of cell strips, weld strength, and environmental stress crack resistance, following ASTM and ISO methods including ASTM D1505, D638, D4218, ISO 1183-1, and ISO 527-3.

Additional inspections are conducted for cell height accuracy, weld spacing tolerance, UV resistance, et surface uniformity before shipment.

Comprehensive dimensional and performance testing ensures that every geocell roll meets international specifications for durability and load-bearing reliability.

If required, customized inspection reports, third-party verification, et factory audit cooperation can be arranged to meet specific project or regional standards.

Pourquoi Travail Avec nous

Contrôle qualité stable avec des délais de livraison fiables dans le monde entier.

Rapports de tests tiers et enregistrements d'assurance qualité traçables inclus.

Conseils de conception, assistance sur site ou à distance et service après-vente.

Ready to Specify a Geocell?

- Plus de 15 ans d'expertise en usine

- Solutions sur mesure pour vos besoins

- Expédition mondiale & Support logistique

- Une citation transparente et sans obligation

- 100% Confidentialité Garantie

Vos informations de courrier électronique resteront strictement confidentielles et notre personnel commercial veillera à ce que vos informations privées soient absolument en sécurité !

Contact

- info@waterproofspecialist.com

Répondre dans les 12 heures!

Veuillez faire attention à l'e-mail avec le suffixe "@ Étanche-épiscial.com".