Uniaxial Geogrid— Manufacturer, Properties &Engineering Applications

Reinforce soil with high-strength HDPE / PP uniaxial geogrid — ideal for slopes, retaining walls, and embankments. Factory-direct supply with quality assurance.

Exportar Globalmente

Directamente de fábrica

Calidad certificada

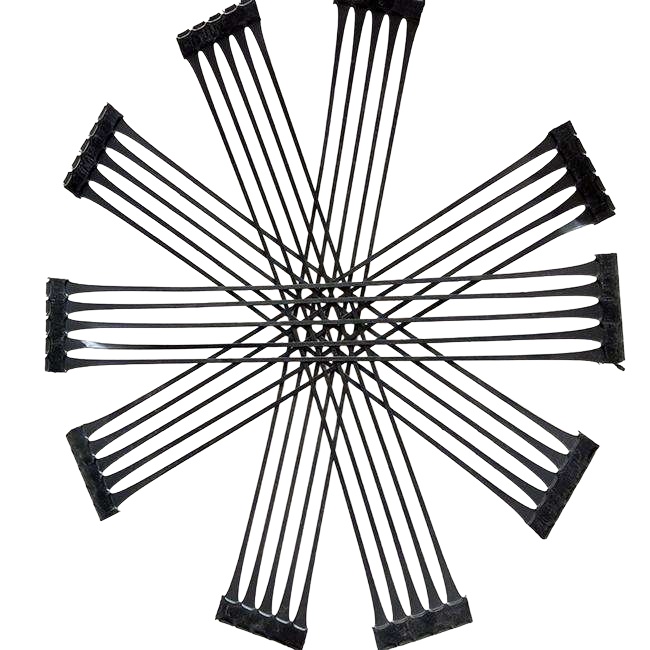

Special Properties of Geomalla uniaxial

DirectionThe uniaxial geogrid provides exceptional tensile strength along the machine direction (MD), which efficiently resists soil deformation and enhances load-bearing capacity in retaining walls and slopes.

Made from high-density polyethylene (HDPE) or polypropylene (PP), it exhibits minimal creep under sustained loading, ensuring reliable long-term reinforcement for soil structures.

Resistant to acids, alkalis, and microbial degradation, allowing stable performance in aggressive soil or drainage environments.

The UV-stabilized polymer structure maintains mechanical strength and dimensional stability even after prolonged outdoor exposure.

The rib and aperture geometry of the uniaxial geogrid enhances interlock with surrounding soil particles, improving shear resistance and reinforcement efficiency.

Rolls are flexible and easy to handle, reducing on-site labor costs and speeding up construction without heavy equipment.

Works effectively with cohesive and granular soils, cement-treated layers, and geotechnical composites for wide engineering applications.

Due to its directional strength and low elongation, it transfers loads efficiently from weak subgrade to stronger soil layers, improving overall structural integrity.

Llegar a saber Geomalla uniaxial

A geomalla uniaxial is a geosynthetic material made from high-density polyethylene (HDPE) or polypropylene (PP), designed to provide reinforcement in one primary direction. During manufacturing, the polymer sheet is extruded, punched, and then stretched longitudinally to align molecular chains.

This process creates high tensile strength along the machine direction, making uniaxial geogrids ideal for soil reinforcement in retaining walls, embankments, and steep slopes where loads act mainly in one direction.

El tensile strength of uniaxial geogrids typically ranges from 30 kN/m to 200 kN/m, depending on the grade and raw material (HDPE, PP, or PET).

They offer high yield strength with very low elongation at break—usually less than 13%.

Such strong directional performance allows them to transfer loads efficiently into the surrounding soil, prevent lateral spreading, and improve the stability of engineered structures.

The term “uniaxial mineral” comes from crystallography and refers to minerals that have a single optical axis, such as quartz or calcite.

It is not related to uniaxial geogrids.

In geotechnical engineering, the word uniaxial simply means “having one principal direction of strength or stress.”

Therefore, when referring to a geomalla uniaxial, it describes a material that resists tension in one direction—not a geological mineral.

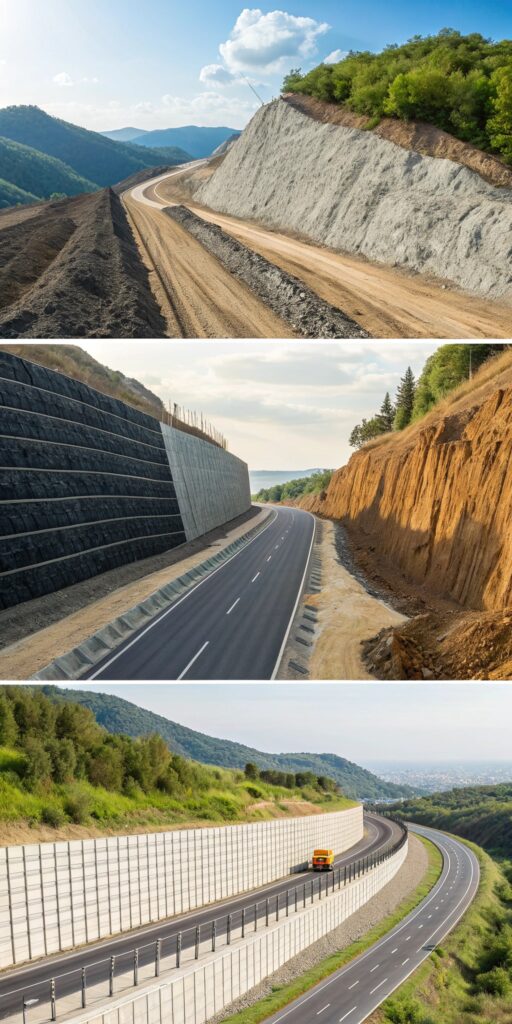

El main purpose of a uniaxial geogrid is to reinforce soil and improve its mechanical behavior under load.

By interlocking with surrounding soil particles, it increases shear resistance, limits deformation, and provides structural stability for retaining walls, embankments, steep slopes, and landfill sidewalls.

In civil engineering projects, it serves as a cost-effective reinforcement layer that enhances load distribution and prolongs the life of infrastructure built on weak or unstable soils.

Tipos de materiales de Geomalla uniaxial

PP Uniaxial Geogrid

PP uniaxial geogrid is made from high-quality polypropylene (PP) through extrusion, perforation, and single-direction stretching. The process aligns polymer chains into a linear structure, providing alta resistencia a la tracción and stability in one direction. Lightweight, flexible, and resistant to chemical corrosion, PP uniaxial geogrid is a cost-effective solution for general soil reinforcement, retaining walls, and drainage slopes. Typical tensile strength: 30–120 kN/m.

HDPE Uniaxial Geogrid

HDPE uniaxial geogrid is produced from high-molecular-weight HDPE sheets that are extruded, punched, and stretched to achieve strong molecular orientation. It offers excellent tensile and creep resistance, outstanding durability, and high UV and chemical stability. Ideal for long-term soil reinforcement, steep slopes, embankments, and retaining walls under heavy load conditions. Typical tensile strength: 60–200 kN/m.

Especificaciones técnicas de Uniaxial Geogrid(PP & HDPE)

| Specification (TGDG model) | Resistencia a la tracción ≥ (kN/m) | Elongación de rotura ≤ (%) | Resistencia al 2% Deformación ≥ (kN/m) | Resistencia al 5% Deformación ≥ (kN/m) |

|---|---|---|---|---|

| TGDG35 | 35 | 10 | 10 | 22 |

| TGDG50 | 50 | 10 | 12 | 28 |

| TGDG80 | 80 | 10 | 26 | 48 |

| TGDG110 | 110 | 10 | 32 | 64 |

| TGDG120 | 120 | 10 | 36 | 72 |

| TGDG150 | 150 | 10 | 42 | 84 |

| TGDG160 | 160 | 10 | 45 | 90 |

| TGDG200 | 200 | 10 | 56 | 112 |

| TGDG220 | 220 | 10 | 80 | 156 |

| TGDG260 | 260 | 10 | 94 | 185 |

| TGDG300 | 300 | 10 | 108 | 213 |

| Specification (TGDG model) | Resistencia a la tracción ≥ (kN/m) | Elongación de rotura ≤ (%) | Resistencia al 2% Deformación ≥ (kN/m) | Resistencia al 5% Deformación ≥ (kN/m) |

|---|---|---|---|---|

| TGDG50 | 50 | 11.5 | 12 | 23 |

| TGDG65 | 65 | 11.5 | 16 | 31 |

| TGDG80 | 80 | 11.5 | 21 | 40 |

| TGDG90 | 90 | 11.5 | 24 | 45 |

| TGDG100 | 100 | 11.5 | 26 | 50 |

| TGDG110 | 110 | 11.5 | 29 | 55 |

| TGDG120 | 120 | 11.5 | 38 | 75.5 |

| TGDG150 | 150 | 11.5 | 41 | 81 |

| TGDG170 | 170 | 11.5 | 52.5 | 103 |

| TGDG200 | 200 | 11.5 | 60 | 110 |

| TGDG220 | 220 | 11.5 | 64 | 127 |

PP vs HDPE Uniaxial Geogrid: Key Differences & Engineering Applications

Both PP (polypropylene) and HDPE (high-density polyethylene) uniaxial geogrids are designed for soilreinforcement, but they differ in long-term performance, creep resistance, and suitability for various engineeringconditions. The following comparison helps you select the right material for your project.

| Comparison Aspect | PP Uniaxial Geogrid (Polypropylene) | HDPE Uniaxial Geogrid (High-Density Polyethylene) |

|---|---|---|

| Material & Structure | Made from high-quality polypropylene sheets through extrusion and unidirectional stretching. Lightweight, flexible, and easy to install. | Made from high-density polyethylene sheets with molecular alignment in one direction. Dense, strong, and more rigid in structure. |

| Resistencia a la tracción | Typically 30–160 kN/m. Suitable for medium-strength soil reinforcement and slope stabilization. | Ranges from 60–220 kN/m. Designed for heavy-load and long-term retaining wall projects. |

| Resistencia a la fluencia | Moderate creep resistance. Recommended for short to medium service-life projects. | Excellent long-term creep resistance — 2–3× higher than PP. Ideal for “hundred-year” engineering structures. |

| Chemical & Environmental Resistance | Resists acids and alkalis, suitable for general soil and drainage environments. | Superior UV and weather resistance. Performs well in coastal, landfill, and high-temperature conditions. |

| Installation & Cost | Lightweight and easy to handle, offering a more economical solution. | Heavier material and higher cost, but with extended service life and stability. |

| Aplicaciones típicas de ingeniería |

• Roadbed & slope reinforcement • Temporary retaining structures • General soil stabilization projects |

• Permanent retaining walls & embankments • Landfill & port revetments • Mining, high-load, and coastal projects |

| Recommended Use | When the project requires quick installation and cost efficiency with moderate load capacity. | When long-term performance, minimal deformation, and environmental durability are priorities. |

In summary: Choose PP Uniaxial Geogrid for standard road or slope reinforcement where cost efficiency matters, and select HDPE Uniaxial Geogrid for high-strength, long-life retaining or foundation structures where durability and creep resistance are critical.

Geomalla uniaxial Installation&Quality Control (CQA)

Métodos de colocación

Preparación de la superficie:

Ensure the foundation surface is smooth, compacted, and free from sharp debris or standing water that could damage the geogrid. Check the design level and alignment before installation to maintain surface uniformity.

Unrolling & Orientation:

Uniaxial geogrids are supplied in rolls and should be unrolled manually or using light machinery along the prepared subgrade.

El main tensile direction must be aligned with the soil’s principal stress direction or load-bearing path to achieve full reinforcement performance. Misalignment greater than 5° can significantly reduce tensile efficiency.

Overlap Width:

For effective load transfer, the longitudinal overlap should be 300–500 mm, y la superposición transversal debe ser at least 500 mm.

Fix the overlaps using U-shaped nails, pins, or plastic ties at intervals of no more than 1.5 m to prevent slippage during backfilling.

Anchoring & Fixation:

At slopes or retaining wall interfaces, anchor the ends of the geogrid beneath a minimum 2 m soil cover or inside a trench.

Apply slight pre-tension to remove wrinkles and ensure even stress distribution across the grid.

Backfilling & Protection:

Spread and compact backfill material evenly in layers. Maintain a minimum cover thickness of 15–20 cm before compaction.

Avoid operating heavy machinery directly on exposed geogrids—ensure proper protection before traffic loading.

Adjustment for Curved or Irregular Areas:

For curved alignments, corners, or culvert edges, lay the geogrid in shorter segments while keeping the main tensile axis consistent with the direction of maximum soil tension.

Maintain a minimum bending radius of 3 m to prevent structural damage to the ribs or junctions.

CQA Recommendations

Conduct visual inspection before and after installation to detect cuts, folds, or misalignment.

Verify that the main tensile direction corresponds to the design drawings and field layout plan.

Ensure overlap and anchoring practices comply with project specifications and international testing standards such as ASTM D6637 o ISO 10319.

During backfilling and compaction, closely monitor for displacement or wrinkles to maintain full contact between the geogrid and the fill material.

Keep installation records and site photos for quality documentation and future maintenance reference.

¿Por qué elegir? ¿Especialista en WP?

A lo largo de los años, Especialista en WordPress se ha establecido como uno de los confiables de China uniaxial geogrid manufacturers y proveedores confiables de materiales de refuerzo geosintéticos para proyectos de infraestructura global.

Nos especializamos en producir high-performance PP and HDPE uniaxial geogrids diseñado para mejorar la estabilidad del suelo, la capacidad de carga y el rendimiento a largo plazo en Muros de contención, taludes, terraplenes y cimientos de carreteras..

Nuestras geomallas ofrecen excepcional resistencia a la tracción, resistencia a la fluencia y durabilidad — respaldado por suministro directo de fábrica, orientación técnica profesional y estricto control de calidad.

- Free Samples of Uniaxial Geogrid

- Soporte experto en proyectos

- Garantía de calidad confiable

- Más de 10 años de experiencia en fabricación

- Suministro directo de fábrica

¿Listo para especificar una geomalla?

- Más de 15 años de experiencia directa de fábrica

- Soluciones de ingeniería personalizada para sus necesidades

- Envío global & Soporte logístico

- Una cita transparente y sin compromiso

- 100% Confdencialidad garantizada

Su información de correo electrónico se mantendrá estrictamente confidencial y nuestro personal comercial se asegurará de que su información privada esté absolutamente segura.

Contacto

- info@waterprowpecialist.com

Responder dentro de las 12 horas!

Preste atención al correo electrónico con el sufijo "@Waterproofpecialist.com".