When developing an anaerobic digestion (AD) project, the choice of geomembrane is a critical decision that directly impacts efficiency, safety, and long-term profitability. These engineered liners perform a crucial dual function: they provide secure liquid containment for the digestate while also forming a gas-tight seal to capture valuable biogas. A failure in either function compromises the entire system.

This guide provides a clear answer to a common question we receive from engineers and project managers: what type of geomembrane is best for AD and biogas systems? We will cover the essential performance requirements, compare the primary materials used, and explain how to select the right combination for a successful, long-lasting project.

Performance Requirements for Geomembranes in Anaerobic Digestion

The environment inside an anaerobic digester is uniquely challenging. Unlike a standard water reservoir or landfill, a biogas system subjects the liner to a combination of aggressive chemicals, constant gas pressure, and elevated temperatures. Therefore, the geomembrane must meet a specific set of performance criteria.

- Resistance to Biogas Components: The liner must be impermeable and chemically resistant to methane (CH₄), carbon dioxide (CO₂), and corrosive trace gases like hydrogen sulfide (H₂S). H₂S, in particular, can degrade certain materials over time, so resistance is non-negotiable.

- Resistance to Organic Acids and Digestate: The biological process creates a cocktail of volatile fatty acids and other organic compounds. The geomembrane must maintain its integrity without swelling, shrinking, or losing its mechanical properties when in constant contact with this chemically aggressive liquid.

- Gas Impermeability and Leak Prevention: The primary economic goal of a biogas plant is to capture methane. The liner material must have an extremely low gas transmission rate to prevent the loss of valuable biogas to the atmosphere. This directly impacts the project's revenue.

- Flexibility for Floating Covers and Domes: For biogas collection, floating covers must be flexible enough to rise and fall with gas production. The material needs high elongation and stress-crack resistance to handle this dynamic movement without failing.

- Long-Term Durability Under Continuous Gas Pressure: The gas trapped under a cover exerts a constant upward pressure. The liner and its seams must be strong enough to withstand this load for decades without creeping or rupturing.

- Reliable Welding for Gas-Tight Seams: The geomembrane panels are joined on-site by thermal welding. The quality of these seams is paramount. They must be as strong and as impermeable as the parent material itself to ensure a truly monolithic, gas-tight containment system.

Geomembrane Materials Used Specifically for Anaerobic Digestion Systems

While several polymers can be used as liners, two have become the industry standard for modern, large-scale AD facilities due to their superior performance against the criteria above: Polietileno de alta densidad (HDPE) and Linear Low-Density Polyethylene (LLDPE).

HDPE Geomembrane for Anaerobic Digesters

High-Density Polyethylene (HDPE) is the workhorse for primary containment in AD systems. It is the most widely specified material for lining the bottom and sides of digesters.

Typically Used For:

- Lining concrete or steel digestion tanks to provide a chemically resistant barrier.

- Primary and secondary containment in large, earthen anaerobic lagoons.

- Lining digestate storage ponds and pre-treatment areas.

Material Advantages:

- Exceptional Chemical Resistance: HDPE's dense, crystalline molecular structure gives it superior resistance to the wide range of acids, bases, and organic compounds found in digestate. From our experience, it offers the best long-term stability in this aggressive environment.

- High Strength and Durability: It has excellent tensile strength and puncture resistance, making it suitable for withstanding the stresses of construction and long-term operation. Based on industry standards like GRI-GM13, a quality HDPE liner can have a service life of 30 to 50 years.

- Excellent Gas-Tightness: HDPE has a very low permeability coefficient, making it highly effective at containing methane and preventing revenue loss.

LLDPE Geomembrane for Biogas Covers

Linear Low-Density Polyethylene (LLDPE) is valued for its flexibility. This makes it the ideal material for dynamic applications where movement and elongation are required.

Typically Used For:

- Floating covers that rise and fall with gas volume.

- Flexible gas domes and storage bags (gas holders).

- Lining irregularly shaped tanks or areas prone to differential settlement.

Material Advantages:

- Superior Flexibility and Elongation: LLDPE can stretch significantly more than HDPE before breaking. This allows it to conform to irregular shapes and handle the stress of a floating cover that is constantly in motion.

- Excellent Stress Crack Resistance: Its pliable nature makes it highly resistant to environmental stress cracking, which is a key failure mode for rigid materials under constant flexing.

- Easier to Handle in Complex Geometries: The flexibility of LLDPE simplifies installation around pipes, sumps, and other details, making it easier to achieve a perfect seal.

HDPE vs. LLDPE Liners for Anaerobic Digestion and Biogas Applications

The core of selecting the right material is understanding that HDPE and LLDPE are not interchangeable. They are engineered materials with distinct properties that make them suitable for different roles within the same system.

HDPE Liners in Anaerobic Digestion: Pros and Cons

Advantages:

- Maximum Chemical Stability: As the primary containment barrier in direct contact with the raw digestate, HDPE's robust chemical resistance provides the highest level of security against long-term degradation.

- High Puncture and Abrasion Resistance: Its rigid nature provides excellent protection against punctures from subgrade imperfections or accidental damage during cleaning and maintenance.

Limitations:

- Lower Flexibility: HDPE is relatively stiff. It is not well-suited for applications requiring significant flexing or folding, such as a floating cover. Its stiffness can also lead to stress concentrations if it is forced into tight corners.

LLDPE Liners in Biogas Systems: Pros and Cons

Advantages:

- Excellent Flexibility: This is its defining feature. It can handle the daily expansion and contraction of a biogas holder without developing fatigue cracks, ensuring long-term gas tightness.

- Conformability: It easily drapes over imperfections and accommodates ground settlement, reducing stress on the material and its seams.

Limitations:

- Slightly Lower Chemical Resistance: While still very good, its chemical resistance is generally considered slightly less broad than HDPE's. This is why it is used as a cover, where it primarily contacts biogas rather than the most concentrated liquid digestate.

- Requires Careful Design: Floating cover systems using LLDPE require careful engineering of weights, floats, and anchoring to manage gas pressure and rainwater effectively.

HDPE vs. LLDPE Comparison for Anaerobic Digesters

This table provides a direct comparison of the two materials for the key requirements of an AD system.

| Requirement | HDPE (Polietileno de Alta Densidad) | LLDPE (Linear Low-Density Polyethylene) |

|---|---|---|

| Biogas Containment | Excelente | Excelente |

| Resistencia química | Excellent (Best-in-class) | Muy bien |

| Flexibilidad & Alargamiento | Medium / Low | High / Excellent |

| Resistencia a la punción | Alto | Bien |

| Suitability for Gas Covers | Limited | Excelente |

| Typical Role in AD System | Digester Bottom & Side Lining | Biogas Floating Cover & Gas Holder |

Which Geomembrane Is Better for Anaerobic Digestion Systems?

The answer is not one or the other; it's both, used in a system approach.

- For the bottom and side liners—the primary containment that is always in contact with the most aggressive liquid—HDPE is the superior choice due to its unmatched chemical resistance and durability.

- For the floating cover or gas dome—the component that must be flexible and withstand constant movement—LLDPE is the superior choice.

The most common and effective design we implement for clients is a combination system: a robust HDPE liner for containment and a flexible LLDPE liner for the gas collection cover. This leverages the strengths of both materials to create a secure, efficient, and long-lasting system.

Recommended Geomembrane Thickness for Anaerobic Digestion

The thickness of the geomembrane is an engineering decision based on the expected mechanical stresses. Using a liner that is too thin is a false economy that leads to premature failure.

-

Digester Liners (HDPE):

- 1.5 mm (60 mil): A common specification for many standard-sized lagoons. It offers a good balance of durability and cost.

- 2.0 mm (80 mil): Recommended for large or deep digesters, or in applications with higher operational risk. The extra thickness provides a greater safety factor against hydrostatic pressure and potential punctures.

-

Biogas Covers (LLDPE):

- 1.0 mm (40 mil) – 1.5 mm (60 mil): This range is typical for floating covers. The thickness is chosen to provide sufficient strength to handle gas pressure and environmental stresses (like wind and rain) while remaining flexible enough for proper operation.

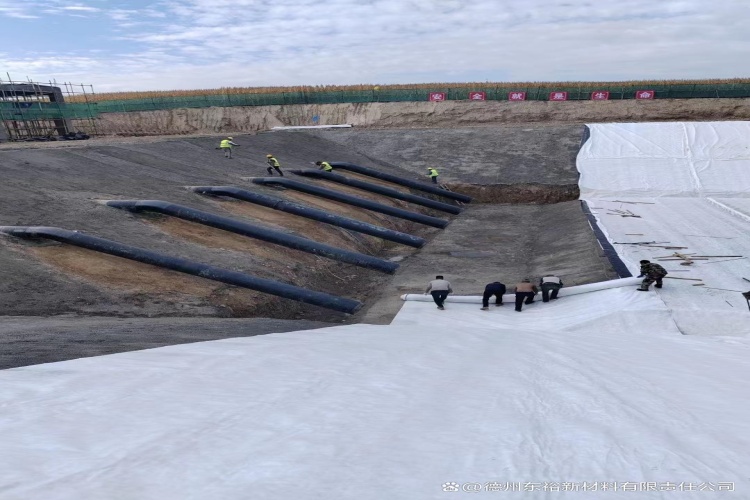

Installation Considerations for Anaerobic Digestion Geomembranes

A perfect material can fail if installed improperly. For AD systems, installation must focus on achieving a 100% gas-tight seal.

- Gas-Tight Welding: All seams must be created using dual-track thermal fusion welders, which create two parallel welds with an air channel in between. This channel is then pressurized to test the integrity of every meter of the seam, ensuring there are no pinholes or imperfections.

- Dual-Membrane Systems with Pressure Control: For high-security applications, sometimes a dual-liner system is used for the cover. Air is pumped between the two membranes to create a slightly inflated dome. This provides structural stability against snow and rain loads and helps manage gas pressure.

- Anchoring Systems: The liner must be securely anchored in a trench around the perimeter of the lagoon. This anchor system is engineered to resist the significant uplift force generated by the trapped biogas.

- Preventing Wrinkles: During deployment, wrinkles must be minimized. These folds can become points of high stress concentration, leading to premature fatigue and cracking over the life of the project.

Conclusión

Both HDPE and LLDPE geomembranes play vital, but different, roles in modern anaerobic digestion facilities. HDPE provides the ultimate chemical-resistant barrier for primary containment, while LLDPE offers the essential flexibility for dynamic gas collection covers. Understanding this system approach is key to maximizing a project's biogas recovery efficiency, ensuring environmental safety, and extending the operational lifespan. We strongly advise that material selection and system design are considered a single, integrated process at the earliest stages of your project planning to mitigate risk and optimize performance.