You've just received a technical data sheet for a geomembrane. It's a wall of numbers and acronyms. You see "thickness," but what about ESCR, OIT, or tensile strength at break? It's overwhelming.

The key specifications for a geomembrane fall into three categories: basic parameters (thickness, material type), mechanical properties (strength, flexibility), and environmental resistance (durability against sun, chemicals, and stress). Understanding these metrics is essential to selecting the right product and ensuring a successful, long-lasting project.

I've had countless clients send me a spec sheet asking, "Is this good?" The truth is, "good" depends entirely on the application. A spec sheet isn't a scorecard; it's a blueprint that tells you what a material is designed to do. Let's break down that blueprint together so you can read it like an expert and make smarter procurement decisions.

What are the basic geomembrane parameters?

You're looking for a liner, and the first questions are always "What material?" and "How thick?" These basic parameters seem simple, but they set the stage for every other performance characteristic.

The basic parameters—material type, thickness, density, and width—define the geomembrane's fundamental identity. They are the first filter used to determine if a product is even a candidate for your project before you analyze its strength or durability.

These are the specs you see first, and for good reason. A 1.5mm PEAD liner for a landfill has a completely different profile than a 0.75mm LLDPE for a pond. Getting these basics right is the first step.

| Basic Parameter | Description | Why It Matters |

|---|---|---|

| Tipo de material | The base polymer (e.g., HDPE, LLDPE, PVC, EVA). | Dictates chemical resistance, flexibility, and temperature range. HDPE is the workhorse for most containment projects. |

| Espesor | Measured in mm or mils (e.g., 1.0mm is 40 mil). | Directly impacts puncture resistance, durability, and cost. Thicker is not always better if flexibility is needed. |

| Densidad (g/cm³) | Distinguishes high-density (≥0.94) from low-density polymers. Tested via ASTM D1505. | High density (HDPE) means higher stiffness and chemical resistance. Lower density (LLDPE) means greater flexibility. |

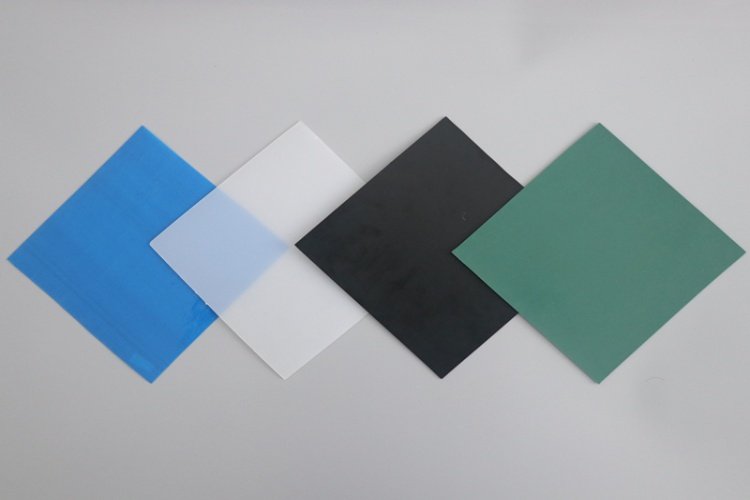

| Color & Width | Typically black for UV resistance (from carbon black). Wide rolls (e.g., 7m) reduce welding seams. | Black is essential for exposed applications. White can be used in hot climates to reduce liner temperature and expansion/contraction. |

What mechanical properties define geomembrane strength?

Your liner will be pulled, stretched, and potentially poked by sharp objects during and after installation. How do you know if it will hold up?

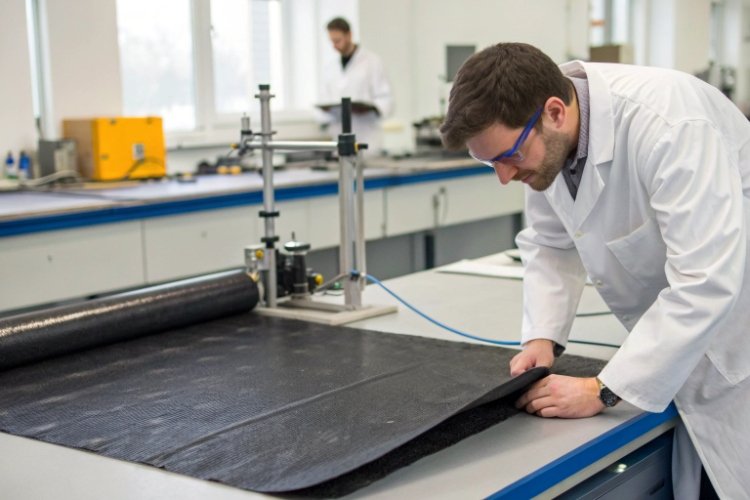

Mechanical properties define how a geomembrane responds to physical force. Tensile strength, elongation, tear resistance, and puncture strength are the critical metrics that ensure the liner can withstand installation stress and long-term ground settlement without failing.

I’ve seen projects fail because the liner couldn’t handle the strain of subgrade settlement. These specs aren't just for the lab; they predict real-world performance. International standards, like the GRI-GM13 for HDPE, set minimum values for these properties to ensure quality.

| Mechanical Property | Standard (e.g., for HDPE) | What It Measures | Why It Matters for Your Project |

|---|---|---|---|

| Resistencia a la tracción | Norma ASTM D6693 | The force required to pull the material apart. | Ensures the liner can resist pulling stresses from soil weight, equipment, and settlement. Critical for slope stability. |

| Alargamiento en rotura | Norma ASTM D6693 | How much the material can stretch before it breaks (as a %). | High elongation (often >700% for HDPE) allows the liner to conform to uneven subgrade and accommodate settlement without rupturing. |

| Resistencia al desgarro | Norma ASTM D1004 | The material's ability to resist the growth of a tear. | Prevents a small nick or cut from propagating into a large failure during installation or settlement. |

| Resistencia a la punción | Norma ASTM D4833 | The force required for a probe to puncture the material. | Protects the liner from sharp stones, roots, or other objects in the subgrade. Essential for almost all applications. |

What environmental resistance parameters matter most?

A geomembrane might look perfect on day one, but its real job is to last for decades while being attacked by sunlight, chemicals, and constant stress. This is where the true quality of a liner is revealed.

Environmental resistance parameters predict the geomembrane's long-term durability. Key metrics like Stress Crack Resistance (ESCR), UV resistance (via carbon black), and OIT measure how well the liner will fight off degradation over its service life.

From my experience, failures that occur 5-10 years after installation are almost always linked to poor environmental resistance. Paying close attention to these parameters is the best way to ensure you are buying a product designed for longevity, not just for passing an initial inspection.

| Durability Parameter | Standard (for HDPE) | What It Measures | Why It's Critical for Long-Term Performance |

|---|---|---|---|

| Resistencia al agrietamiento por tensión (ESCR) | ASTM D5397 (NCTL Test) | The material's ability to resist slow crack growth when under long-term stress. | This is arguably the most critical parameter for landfill and mining applications. It prevents failures from long-term, low-level stress. |

| Contenido de negro de humo | ASTM D1603 | The percentage of carbon black in the polymer (typically 2-3%). | Carbon black is the primary defense against UV radiation (sunlight), which would otherwise rapidly degrade the polymer. |

| Carbon Black Dispersion | ASTM D5596 | How uniformly the carbon black is distributed, graded from A1 to C5. | Poor dispersion creates weak spots vulnerable to UV attack. A good spec requires 9 of 10 views to be A1 or A2. |

| Oxidative Induction Time (OIT)) ASTM D3895 | The time it takes for the antioxidant package in the liner to be consumed under heat. | OIT is a direct measure of the liner's resistance to chemical degradation from heat and oxidation, a key predictor of service life. |

What other key parameters affect geomembrane performance?

The material itself can be perfect, but it's only one part of a complete containment system. A couple of other parameters determine how the liner functions once it's installed on your site.

Permeability, seam strength, and interface friction are system-level parameters. They ensure the installed liner is truly waterproof, its joints are secure, and it remains stable on sloped surfaces, making the entire system safe and effective.

I once consulted on a project where the contractor used a smooth geomembrane on a steep slope. The material specs were excellent, but the system was unstable. They saved a few cents per square meter but had to redo the entire section with a textured liner. This is a perfect example of why these final parameters are so critical.

| System Parameter | Standard (for HDPE) | What It Measures | Why It Defines System Success |

|---|---|---|---|

| Permeabilidad | Norma ASTM D5887 | The rate at which water can pass through. | Geomembranes are considered effectively impermeable. The spec ensures you are getting a true barrier, not just a water-resistant layer. |

| Weld Seam Strength | ASTM D6392 / GRI-GM19 | The strength of the heat-welded seams (tested for peel and shear). | A liner system is only as strong as its weakest point. Seams must be as strong or stronger than the parent material to prevent leaks. |

| Interface Friction Angle | ASTM D5321 | The friction between the geomembrane and soil or other geosynthetics. | For any project with slopes (landfills, dams, canals), a textured surface with a high friction angle is required to prevent sliding failure. |

Conclusión

A geomembrane data sheet is a story. It tells you a material's strength, its durability, and the applications it's built for. Learning to read it is the key to a successful project.