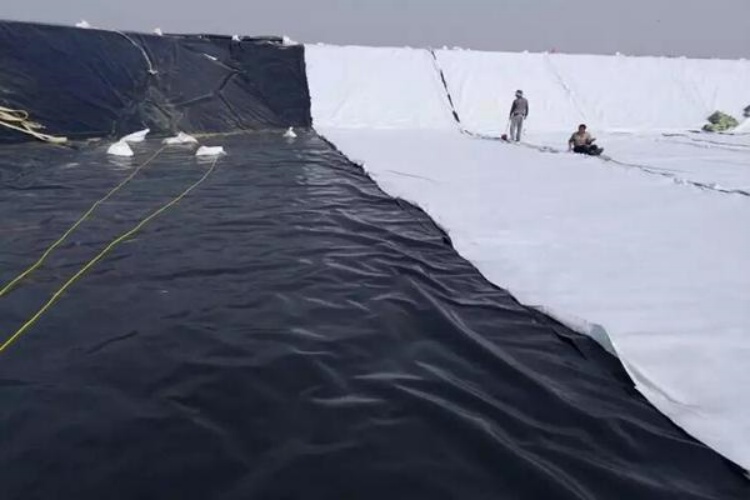

You've successfully laid a geomembrane on a steep slope, but a critical question remains: how do you stop it from sliding down? An improperly anchored liner is a ticking time bomb, ready to tear under its own weight and cause a complete system failure.

The most common and reliable method is securing the geomembrane in an “anchor trench” dug at the top of the slope. The liner is placed into the trench, which is then backfilled with compacted soil, using the soil's weight to create a powerful, permanent anchor.

como un supplier, I've seen projects succeed or fail based on this one critical detail. The anchor trench is a fantastic default, but it's not the only solution, especially when dealing with hard surfaces like concrete walls. The right method depends entirely on the specific conditions of your project's slope, or what we often call the "vertical face." Let's explore how to make the right choice to ensure your liner stays put for decades.

What site and slope conditions determine the appropriate anchoring method?

Choosing an anchoring method without analyzing the site is like building without a blueprint. You risk selecting a system that's too weak for the load, too expensive for the need, or simply incompatible with the surface you're working with.

The key conditions are the slope type (soil vs. concrete), the slope angle, and the expected loads from soil and water pressure. These factors dictate whether you need simple friction or a robust mechanical fastening system to ensure long-term stability.

Before I recommend any anchoring system to a client, I always walk them through four fundamental principles. These are the core questions you must answer to select the right method for your site.

| Guiding Principle | Key Question to Ask | Why It Matters for Anchoring |

|---|---|---|

| Sealing Integrity | Will this method create a perfect seal between the geomembrane and the slope? | The primary goal is to prevent leaks. The anchor must not create a pathway for water to get behind the liner. |

| Stability | Can the anchor system withstand all design loads (soil, water, wind) without failing? | The anchor is the only thing fighting gravity and other forces. It must be stronger than the highest expected load. |

| Adaptability | Can the anchoring system accommodate minor ground settlement or temperature changes? | A rigid system on a settling foundation can create stress points and tear the liner. The anchor needs some flexibility. |

| Durabilidad | Are the anchoring materials resistant to corrosion, UV rays, and aging for the project's entire lifespan? | An anchor that rusts or degrades will fail, compromising the entire project years after installation. |

Answering these questions first ensures that you don't just pick a method, but you pick the right method for your specific near-vertical face or gentle embankment.

Which anchoring techniques are commonly used on sloped surfaces?

With options ranging from simple trenches to complex bolting systems, it's easy to get confused. Choosing the wrong one for your slope can lead to installation headaches, premature failure, and costly repairs down the line.

The most common method for soil slopes is the anchor trench. For structural walls like concrete, mechanical fastening with batten strips and anchor bolts is standard. Ballast systems and soil anchors are used in more specialized situations.

I supply materials for all these methods, and each has a specific place where it excels. Here’s a breakdown of the most common techniques I see used in projects from landfills to reservoirs.

| Anchoring Technique | Best Used For | How It Works |

|---|---|---|

| Anchor Trench (Most Common) | Soil slopes, landfill cells, earthen dams, and canal banks. | A trench is dug at the top crest of the slope. The geomembrane is laid inside, and the trench is backfilled with compacted soil. The weight and friction of the soil lock the liner in place. |

| Mechanical Fastening | Concrete walls, structural foundations, and building basements. | A rigid metal or plastic bar (batten strip) is placed over the geomembrane and fastened directly to the wall using expansion bolts or specialized screws. This creates a strong, direct connection. |

| Soil Anchoring | Soft soil slopes or embankments where a trench isn't feasible. | Long steel rods or soil nails are driven deep into the embankment face, passing through the geomembrane. They use the friction between the anchor and the deeper, stable soil to hold the liner. Requires geotechnical analysis. |

| Hybrid: Welding + Mechanical | High-security waterproof applications where a perfect seal is critical. | The edge of the geomembrane is first heat-welded to a compatible material on the wall. Then, a mechanical fastening system is installed over the weld for added stability. This combines the seal of welding with the strength of bolts. |

| Chemical Anchoring | Complex, irregular surfaces where drilling for mechanical fasteners is difficult. | Chemical adhesive is injected into a pre-drilled hole to bond an anchor bolt to the wall. The geomembrane is then attached to this bolt. This requires careful consideration of material compatibility. |

For most of my clients working on earthen projects, the anchor trench is the go-to solution for its simplicity, cost-effectiveness, and proven reliability.

How do soil type, slope gradient, and subgrade stability influence the performance of geomembrane anchoring systems?

You know the techniques, but why does a simple trench work perfectly on one slope but would fail miserably on another? The answer lies in the ground itself. The forces acting on your anchor change dramatically with the geology of the site.

These factors directly control the pull-out forces acting on the anchor. A steep, unstable slope with loose soil exerts far more tensile load on the geomembrane than a gentle, solid one, demanding a much stronger and deeper anchoring solution.

The performance of your anchoring system is a battle against physics, and the site conditions are the rules of engagement. I always tell my clients to pay close attention to these three factors, as they dictate the engineering requirements.

-

Soil Type: The holding power of an anchor trench depends entirely on the soil's shear strength and weight.

- Poor Condition: In loose, sandy, or low-friction soil, a standard anchor trench may not have enough weight or grip to hold the liner. The trench needs to be designed wider and deeper to compensate.

- Good Condition: In dense, compacted clay, a smaller trench can provide excellent holding power, saving time and excavation costs.

-

Slope Gradient: This is the most obvious factor. The steeper the slope, the greater the gravitational force trying to pull the geomembrane down.

- Poor Condition: On a near-vertical wall or a steep 2:1 slope, the tensile load on the anchor system is immense. This is where methods like mechanical fastening or deep soil anchors become necessary. A simple trench would fail.

- Good Condition: On a gentle 4:1 slope, the gravitational pull is much lower, and a standard, well-compacted anchor trench is more than sufficient.

-

Subgrade Stability: A stable foundation is key. If the ground underneath is prone to movement, the anchor must be able to adapt.

- Poor Condition: On slopes made of settling fill material, a rigid anchoring system like tightly bolted battens can create stress points and tear the geomembrane as the ground moves. A more flexible system or one with slack is needed.

- Good Condition: On a stable vertical concrete wall or solid bedrock, a rigid mechanical system is ideal because there is no risk of differential settlement.

How can I evaluate long-term stability and safety to ensure reliable geomembrane anchoring on slopes?

The installation is complete, and the anchor is buried. How can you be confident that it will hold for the next 30 years? The answer is not hope; it's a rigorous quality control program during installation.

Long-term stability is verified through a strict quality control program during and after installation. This includes surface preparation, material testing, weld inspection, and mechanical pull-out tests on the anchors to confirm their design holding capacity.

You can't see the anchor once it's buried, so you have to trust the work that was done. This trust comes from verification. Based on my experience with countless successful projects, a solid quality assurance plan is non-negotiable. It should always include these four critical steps.

-

Thorough Surface Preparation: Before any anchoring begins, the vertical wall or slope surface must be pristine. It needs to be clean, dry, free of oil and debris, and smooth. For some applications, we even recommend roughing up the surface to improve the bond and friction with the geomembrane.

-

Strict Temperature Control: If any heat welding is involved, especially in hybrid systems, the ambient temperature and the material temperature must be within the manufacturer's specified range. Welding when it's too cold can result in a brittle, weak seam that will fail under stress.

-

Meticulous Detail Work: Failures often happen at the small, tricky spots. All corners, pipe penetrations, and anchor points must be treated with extreme care. These are the areas that need extra reinforcement and sealing to ensure the entire system is waterproof and stable.

-

Rigorous Quality Monitoring and Testing: This is how you prove the anchor's strength. The process should include material inspection upon delivery, non-destructive and destructive testing of all welds, and most importantly for anchors, pull-out tests. A percentage of the mechanical or soil anchors should be tested with a calibrated load to ensure they meet or exceed the design pull-out strength. This is your ultimate proof of long-term stability.

Conclusión

Proper anchoring is not an optional extra; it is a fundamental requirement for any sloped geomembrane project. By matching the anchoring method to your site conditions and performing rigorous quality control, you ensure long-term success.