EVA Geomembrane — Flexible Waterproof Liner for Tunnels, Subways & Underground Projects

Ethylene-vinyl acetate (EVA) geomembrane liners designed for underground waterproofing and special engineering projects. Superior flexibility, 0.8–3.0 mm thickness, factory-direct supply and global delivery.

Referencia ASTM/GRI/ISO

Directamente de fábrica

Exportar Globalmente

Propiedades principales de EVA Geomembrane

EVA geomembrane maintains elongation and shape even at low temperatures, ensuring reliable performance on complex ground surfaces.

EVA liner absorbs strong dynamic impact energy, making it suitable for heavy machinery loads and pressure resistance.

With balanced static and dynamic puncture strength, EVA geomembrane provides durable protection against punctures and mechanical damage.

EVA geomembrane resists acids, alkalis, and certain organic solvents, ensuring long-term chemical durability.

Enhanced with antioxidants, EVA geomembrane offers superior aging resistance and UV stability for outdoor applications.

Performs reliably between -70°C and 80°C, with better performance than PVC and HDPE liners under extreme conditions.

Made without halogens or heavy metal additives, EVA geomembrane is safe, recyclable, and environmentally friendly.

Llegar a saber EVA Geomembrane

EVA geomembrane is a waterproof liner made from ethylene-vinyl acetate (EVA) material. It combines high flexibility, elasticity, and durability, making it ideal for lining projects.

EVA geomembrane is produced from EVA resin blended with stabilizers and anti-aging additives. This unique formulation gives EVA liners excellent weather, chemical, and UV resistance.

EVA geomembranes are commonly manufactured in thicknesses from 00,5 mm a 3,0 mm. The choice of thickness depends on project design, required durability, and site conditions.

EVA geomembrane is widely used in reservoirs, fish ponds, mining projects, waste landfills, and tunnels. The EVA liner adapts well to uneven ground, ensuring reliable long-term protection.

With proper installation and protection, EVA geomembranes can last 15-25 años. Their resistance to UV, chemicals, and extreme temperatures ensures long-term performance.

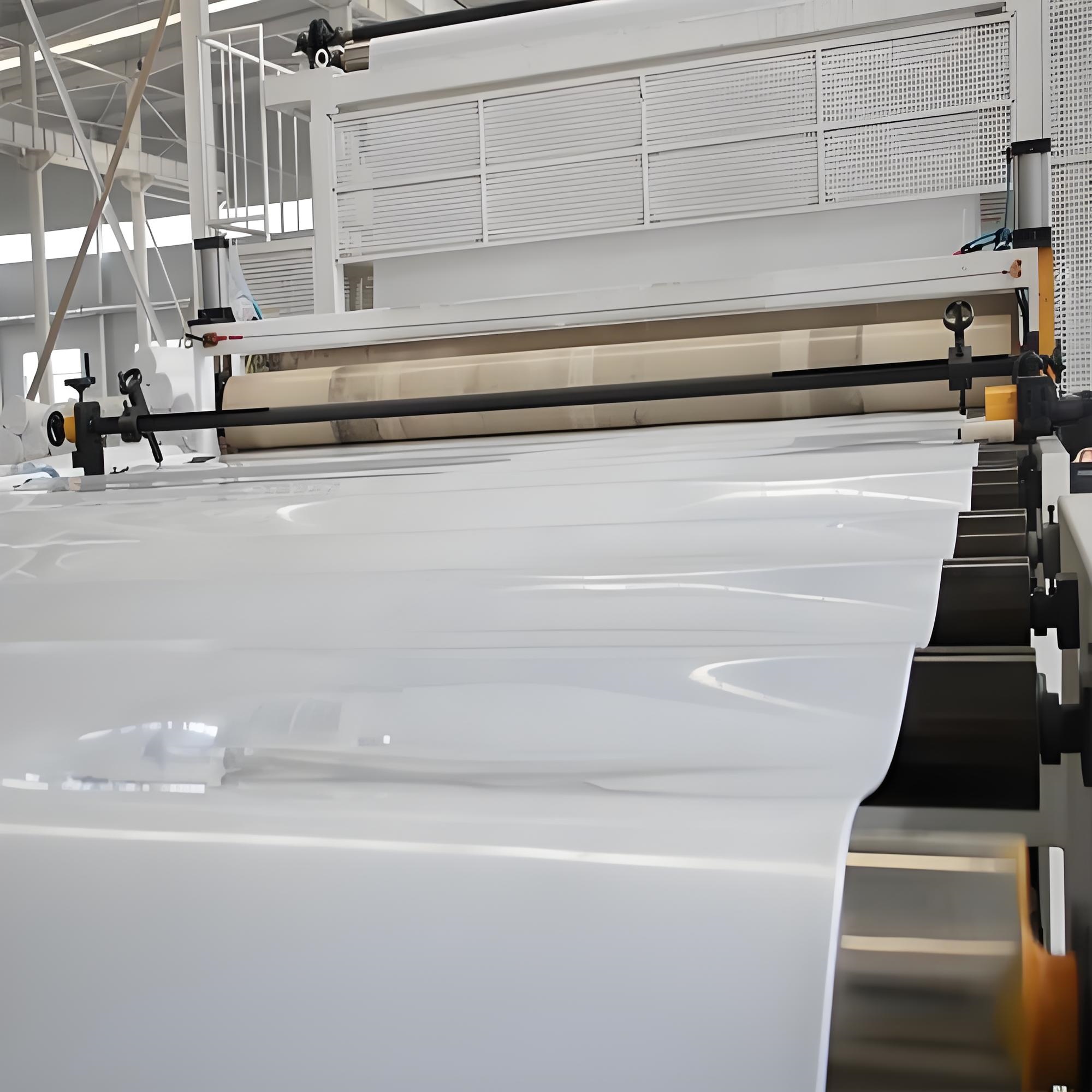

Tipos de superficie y opciones de color of EVA Geomembrane

Surface Type:

Smooth EVA geomembrane – Standard choice for tunnels, basements, and subway waterproofing. Smooth surfaces ensure easy welding and reliable anti-seepage performance.

Color Options:

White EVA geomembrane – Improves visibility inside tunnels and subways, commonly used in underground waterproofing projects.

Gray EVA geomembrane – Popular for basements, foundations, and roof waterproofing.

Black EVA geomembrane – General-purpose waterproof liner for reservoirs and anti-seepage works.

EVA Geomembrane Thickness Guide & Aplicaciones

| Espesor (mm) | Características clave de rendimiento | Aplicaciones típicas | Especificaciones y notas recomendadas |

|---|---|---|---|

| 1,00 milímetros EVA geomembrane liner |

· High dynamic impact absorption · Wide temperature performance · Medium static puncture protection |

· Subgrade lining for light traffic areas · Agricultural irrigation canals · Municipal stormwater reservoirs |

· Smooth or textured EVA geomembrane · Recommend 10 cm sand cushion or geotextile isolation |

| 1,20 milímetros EVA geomembrane sheet |

· Enhanced puncture resistance · Excellent crack propagation resistance · Superior chemical and aging durability |

· Medium-size landfill leachate ponds · Sewage treatment basins · Tunnel waterproofing liners |

· Single or double textured surfaces for higher friction · Combine with geotextile for improved stability |

| 1,50 milímetros EVA waterproof liner |

· High tensile strength & impact resistance · Long-term durability · Excellent root puncture resistance |

· Medium-size landfill capping · Main traffic subgrade channels · External tunnel waterproofing |

· Double textured EVA geomembrane recommended · Seam testing with vacuum or spark detection |

| 2,00 milímetros Engineering-grade EVA liner |

· Extreme puncture and UV resistance · Service life up to 30 years |

· Hazardous waste containment sites · Large sludge concentration basins · Heavy load traffic subgrade lining |

· Multi-layer composite systems · Automated welding & strict seam testing |

| 2,50–3,00 mm Heavy-duty EVA geomembrane |

· Extreme crack resistance & impact resistance · Superior aging performance · Designed for special engineering |

· Nuclear waste storage facilities · Deep foundation waterproofing · Large industrial tailings dams |

· Installed by professional teams · Service life over 30 years |

EVA Geomembrane Specifications, Pruebas y hoja de datos

| Propiedad | Método de prueba (ref.) | Typical Performance | Nota |

|---|---|---|---|

| Densidad | Norma ASTM D1505 | 0.92–0.96 g/cm³ | eva geomembrane density, lighter than PVC |

| Propiedades de tracción (cedimiento y rotura) | Norma ASTM D6693 | Moderate tensile strength, high elongation | good flexibility & break resistance |

| Resistencia al desgarro | Norma ASTM D1004 | Good anti-tear performance | resists crack propagation in thin liners |

| Resistencia a la punción | Norma ASTM D4833 | Moderate to high, depending on thickness | impact & puncture resistance for waterproofing |

| Estabilidad química | ASTM D543 | Resistant to most mild acids & bases | not as strong as HDPE against strong chemicals |

| UV & Weather Resistance | ASTM G154 | Moderate, requires stabilizers | better than LDPE, lower than HDPE |

| Estabilidad dimensional | Norma ASTM D1204 | ±2% | thermal stability under construction conditions |

| Flexibility at Low Temperature | ASTM D746 | Excellent flexibility down to –40℃ | advantage of eva geomembrane over hdpe |

| Vida útil | — | 15–25 years (depending on exposure) | suitable for ponds, tunnels, waterproofing liners |

EVA Geomembrane Installation&Welding

Métodos de soldadura

Soldadura por aire caliente: EVA geomembranes are highly flexible, making them suitable for hot air welding. This ensures smooth seams in applications like tunnels, reservoirs, and basements.

High-Frequency Welding: Especially effective for thin EVA liners (0.5–1.5 mm), providing strong seam bonding with minimal material deformation.

Ancho de superposición: Typically 75–100 mm, smaller than HDPE, since EVA membranes offer excellent flexibility and conform easily to complex structures.

Procedimientos de control de calidad (CQA)

Soldaduras de prueba: Conducted at the start of each workday to confirm correct temperature and pressure for EVA material.

Mapeo de costuras: Each welded seam is logged and traced for inspection, especially in waterproofing projects like underground tunnels or basements.

Archivos: Installation logs should include welding temperature, overlap width, and operator details.

Métodos de prueba

Ensayos No Destructivos (END):

Air Channel Test: Applied to double-track hot air seams.

Prueba de caja de vacío: Ensures no leakage in critical waterproofing areas.

Pruebas Destructivas (DT):

Cáscara & Shear Tests: Carried out on EVA weld samples every 150–300 m² to meet ASTM D6392 requirements.

Compared to HDPE liners, EVA geomembranes are easier to weld, adapt better to irregular foundations, and provide superior flexibility, making them ideal for tunnels, basements, and complex waterproofing projects.

¿Por qué elegir? ¿Especialista en WP?

Over the years, we have established ourselves among trusted EVA geomembrane manufacturers and global EVA geomembrane distributors. Our focus is on delivering reliable liners that meet critical engineering projects.

- Free Samples of EVA Geomembrane Sheet

- Soporte experto en proyectos

- Garantía de calidad confiable

- Más de 10 años de experiencia en fabricación

- Suministro directo de fábrica

Conceptos básicos de Wholesale EVA Geomembrane

Incluya el tipo de proyecto (estanque, vertedero, minería, embalse), espesor requerido, superficie (lisa/texturada), preferencia de tamaño de rollo y condiciones de entrega (FOB/CIF + puerto).

Yes, free EVA geomembrane sheet samples are available for evaluation prior to bulk purchase.

El plazo de entrega típico es de 15 a 25 días para la producción, más el cronograma de envío según el puerto de destino.

El ancho de rollo estándar para exportación es 5,8 metros, que está optimizado para la carga de contenedores. Anchos más largos como 7-8 metros También están disponibles, dependiendo de las condiciones reales de carga del contenedor. La longitud del rollo suele oscilar entre 50-150 metros, ajustado por espesor. Si es necesario, se pueden suministrar paneles prefabricados personalizados.

The weight of an EVA geomembrane liner is calculated as:

Weight (g/m²) = Thickness (mm) × Density (g/cm³) × 1000

For EVA geomembrane with density 0.92–0.96 g/cm³ (per ASTM D792):

A 1.0 mm EVA liner weighs about 920–960 g/m²

A 1.5 mm EVA liner weighs about 1380–1440 g/m²

A 2.0 mm EVA liner weighs about 1840–1920 g/m²

La capacidad se calcula en base a 40HQ ≈ 25 toneladas peso de carga. El número exacto de rollos depende del grosor y del ancho del rollo; Calculamos según el peso del revestimiento por m² y el límite de peso del contenedor.

El pedido mínimo recomendado es 5000 m². Dado que la geomembrana es voluminosa y pesada, sugerimos al menos una Contenedor de 20GP para un envío eficiente. También podemos ayudar en consolidar con otra carga si es necesario.

somos un fabricante chino de geomembranas, y los envíos se pueden organizar desde cualquier puerto chino importante como Qingdao, Shanghai o Ningbo.

¿Listo para especificar una geomembrana?

- Más de 15 años de experiencia directa de fábrica

- Soluciones de ingeniería personalizada para sus necesidades

- Envío global & Soporte logístico

- Una cita transparente y sin compromiso

- 100% Confdencialidad garantizada

¡Su información de correo electrónico se mantendrá estrictamente confidencial y nuestro personal comercial se centrará en que su información privada sea absolutamente segura!

Contacto

- info@waterprowpecialist.com

Responder dentro de las 12 horas!

Preste atención al correo electrónico con el sufijo "@Waterproofpecialist.com".