Choosing the right geocell height is a critical design decision that directly impacts project performance, cost, and long-term stability. Selecting a height that is too low can lead to inadequate load support or slope failure, while over-specifying the height wastes material, increases excavation depth, and inflates project costs. Finding the optimal balance is key to a successful soil stabilization project.

As a supplier of geosynthetics, we've seen how this one parameter can make or break a design. This practical guide is designed to walk you through a systematic process for selecting the correct geocell height. We will cover the key influencing factors, provide detailed recommendations for various applications, and offer a final checklist to help you make an informed decision based on solid engineering principles, not guesswork.

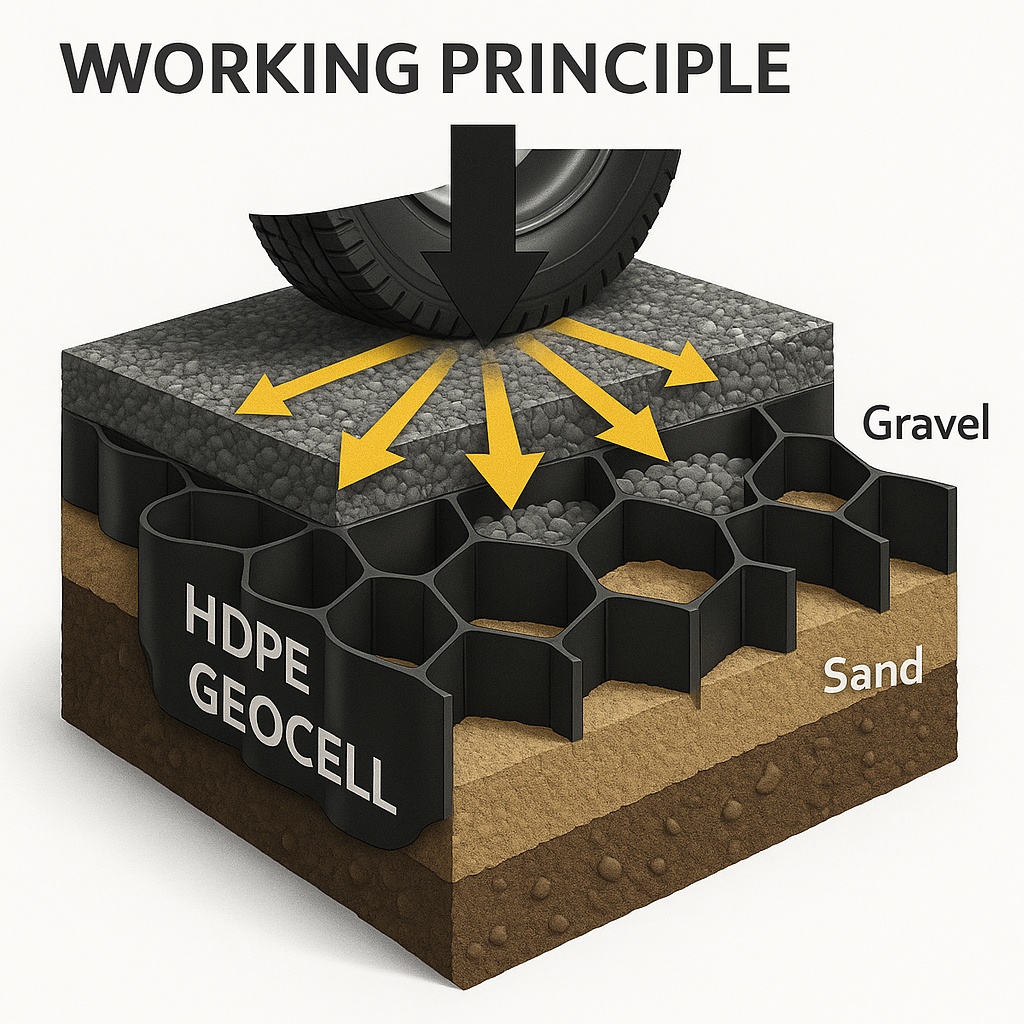

Let's begin by understanding how geocell height functions to improve soil properties.

1. Understanding the Function of Geocell Height

A geocell system works by creating a three-dimensional honeycomb of confinement. When filled with aggregate, sand, or soil, it prevents the lateral movement of the infill particles. This confinement creates a semi-rigid mattress effect that significantly improves the properties of the soil layer.

The height of the geocell is arguably the most important parameter in this system. It directly dictates:

- The Depth of Confinement: Taller cells create a deeper, more robust composite layer, providing a stronger interlock with the infill material.

- Load Distribution: A taller geocell mattress distributes applied vertical loads over a wider area of the subgrade, reducing point pressure and preventing settlement or rutting.

- Lateral Resistance: On slopes, a greater height provides more significant resistance against gravitational and hydraulic forces, preventing erosion and soil sliding.

Essentially, a taller cell creates a mechanically stabilized layer with a higher effective structural number. However, the benefits are not linear, and the goal is to select the minimum height required to meet performance targets, thereby optimizing cost.

2. Key Factors Influencing Geocell Height Selection

Three primary factors govern the selection of geocell height: the strength of the ground you are building on, the weight of what you're putting on top of it, and the type of project you're building.

Subgrade Strength and CBR Requirements

This is the most critical factor. The weaker your subgrade, the more support you need from the geocell system. The California Bearing Ratio (CBR) is a standard measure of subgrade strength.

| Subgrade CBR Value | Subgrade Rating | Recommended Geocell Height | Notas |

|---|---|---|---|

| < 2% | Extremely Weak | 150 mm – 250 mm (6" – 10") | Needs very strong lateral confinement. May also require subgrade stabilization. |

| 2% – 5% | Weak | 100 mm – 150 mm (4" – 6") | Standard applications on poor soils. |

| 5% – 10% | Medium | 75 mm – 100 mm (3" – 4") | A lower height is often sufficient. |

| > 10% | Good | 50 mm – 75 mm (2" – 3") | Subgrade is competent; geocell is mainly for surface stability or erosion control. |

For example, on a project with wet clayey soil (CBR < 2%), a 50 mm geocell alone would be ineffective. The design would require a geocell of at least 100 mm, possibly in conjunction with a soil stabilizer like lime, to achieve the necessary performance.

Expected Load (Traffic, Embankment, Slope Pressure)

The type and magnitude of the load determine the stress the geocell system must endure.

- Static Loads: Embankments, retaining walls, and foundation mattresses. Taller geocells provide a thicker, more stable base.

- Dynamic Loads: Vehicle traffic. Heavier vehicles and higher traffic frequency demand taller geocells to prevent long-term rutting. A 100 mm geocell can increase the rutting life of a road by 1.8 times compared to a 75 mm cell.

Project Type: Road Base, Slope, Channel, Retaining Fill

Different applications have different primary objectives:

- Roads: Need to resist vertical rutting and distribute load.

- Slopes: Need to resist lateral soil movement and erosion.

- Channels: Need to resist hydraulic shear stress from water flow.

3. Recommended Geocell Heights for Different Applications

Based on thousands of projects, clear guidelines have emerged. The most common heights are 100 mm (4"), 150 mm (6"), and 200 mm (8"), which cover the vast majority of applications.

Application Quick-Reference Table

| Height (mm) | Height (in) | Typical Applications | Load Class |

|---|---|---|---|

| 50 mm | 2" | Landscaping, light garden paths, turf protection | Pedestrian (< 500 kg) |

| 75 mm | 3" | Pedestrian walkways, bicycle paths, golf cart paths | Light Duty (< 1,000 kg) |

| 100 mm | 4" | Most Common: Driveways, parking lots, light access roads | Medium Duty (< 3,000 kg) |

| 150 mm | 6" | Commercial parking, emergency access, farm roads | Heavy Duty (< 16,000 kg) |

| 200 mm | 8" | Haul roads, mining sites, intermodal yards, laydown areas | Very Heavy Duty (< 30,000 kg) |

| 250 mm | 10" | Port facilities, airport runways, extreme loads | Extreme Duty (< 60,000 kg) |

For Road Base Reinforcement

- Light Duty (Cars, pedestrian zones): 75 mm to 100 mm is sufficient.

- Medium Duty (Residential roads, commercial lots): 100 mm to 150 mm is the standard. Use 150 mm for areas where delivery trucks are frequent.

- Heavy Duty (Industrial sites, haul roads, emergency access for fire trucks): 150 mm to 200 mm (or more) is required.

For Slope Stabilization

The steeper the slope, the greater the geocell height needed to provide adequate soil confinement and resist gravitational forces.

- Gentle Slopes (< 30° or 1V:3H): 75 mm – 100 mm

- Medium Slopes (30°- 45° or 1V:2H): 100 mm – 150 mm

- Steep Slopes (> 45° or 1V:1.5H): 150 mm – 200 mm

A useful quick estimation formula for slope applications is:

Recommended Cell Height ≈ Slope Height / 8 to 10

For a 10-meter high embankment, this suggests a height of 100 mm to 125 mm, which falls right in the recommended range for medium slopes.

4. Comparing Low, Medium, and High Geocells

The choice of height involves a trade-off between upfront cost and long-term performance.

| Factor | 100 mm (4") Geocell | 150 mm (6") Geocell | The Takeaway |

|---|---|---|---|

| Product Cost | Lower | 20-30% higher than 100 mm | 150 mm has a higher upfront material cost. |

| Infill Volume | Lower | 50% more infill than 100 mm | Taller cells require more aggregate, increasing cost. |

| Excavation Cost | Lower | Higher (deeper excavation required) | Site preparation costs increase with cell height. |

| Performance | Excellent for medium loads | Superior performance for heavy loads | Performance gains diminish beyond 150mm for many uses. |

| Overall ROI | Optimal for most applications | Economical only for heavy-duty projects | 100 mm is the sweet spot for cost-effectiveness. |

For most projects, a 100 mm geocell provides the best return on investment. Moving to 150 mm is only justified when dealing with very weak soils (CBR < 3%) or consistent heavy vehicle traffic.

5. Material and Cell Size Considerations

The geocell product itself also plays a role.

Infill Material Interaction

The type of infill material affects the confinement needed. Coarse, angular gravel has a high friction angle and works well in 75-100 mm cells. Fine sand, which is less stable, benefits from the greater confinement of 100-150 mm cells. Interestingly, research shows that a 100 mm geocell filled with recycled construction aggregates can achieve the same performance as a 150 mm geocell filled with conventional gravel, offering significant cost savings.

Geocell Quality (Wall Thickness and Weld Strength)

Not all geocells are created equal. A high-quality geocell with thicker walls (e.g., 1.5 mm vs. a standard 1.25 mm) and stronger welds provides superior confinement. This means a high-performance 100 mm geocell can often replace a standard-duty 150 mm geocell, saving on material, infill, and excavation costs. Always compare the technical datasheets, not just the height.

6. Common Mistakes in Selecting Geocell Height

- Over-specifying: Choosing a 200 mm height "just to be safe" on a medium-duty road without proper analysis leads to unnecessary expense.

- Under-specifying: Using a 75 mm geocell on a soft, swampy subgrade because it's cheaper will almost certainly result in premature failure.

- Ignoring Infill: Assuming all infill materials perform the same. A fine sand infill requires a taller cell than a crushed stone infill to achieve the same bearing capacity.

7. Practical Selection Checklist for Engineers

Follow this workflow to arrive at a well-reasoned decision.

- Define the Application: Is it a road, slope, channel, or wall? Use the Quick-Reference Table to get an initial height range.

- Assess the Subgrade: What is the CBR value? If it is weak (<5%), adjust your initial selection up by one size (e.g., from 100 mm to 150 mm).

- Confirm the Load Class: What is the heaviest expected vehicle? Check your refined selection against the load classes in the table.

- Consider Climate: For areas with frequent water saturation or freeze-thaw cycles, consider increasing the height by 25-50 mm to improve drainage and stability.

- Evaluate Infill Material: Are you using high-quality angular aggregate or lower-quality local soil/sand? Adjust height accordingly.

- Verify with Standards: Cross-reference your choice with local and international design guides (e.g., AASHTO for low-volume roads), which often recommend 100-150 mm geocells to reduce base course thickness by 30-50%.

Conclusión

While many factors are at play, a clear pattern emerges. For the vast majority of projects, 100 mm (4") geocell is the versatile, cost-effective workhorse. It provides an optimal balance of performance and economy for everything from residential driveways to light commercial roads. Reserve 150 mm (6") geocells for projects with known challenges, such as very weak subgrades or frequent heavy truck traffic. By following a structured selection process, you can confidently choose a height that ensures project success and delivers maximum value.