Managing organic wastewater from farms and food processing plants is a massive operational challenge. While high-tech anaerobic digester tanks offer impressive efficiency, their steep cost and complexity put them out of reach for many projects. So, what is the alternative? For many, the answer remains the humble anaerobic lagoon.

This guide explains what an anaerobic lagoon is, how its key components work, and why it remains a powerful and cost-effective solution for large-scale wastewater treatment. We'll explore how modern geosynthetics have transformed this simple concept into a highly reliable and environmentally secure system.

We will walk through the design fundamentals, key applications, and the critical role that materials like geomembranes and geotextiles play in guaranteeing a lagoon’s long-term performance and safety.

What Is an Anaerobic Lagoon?

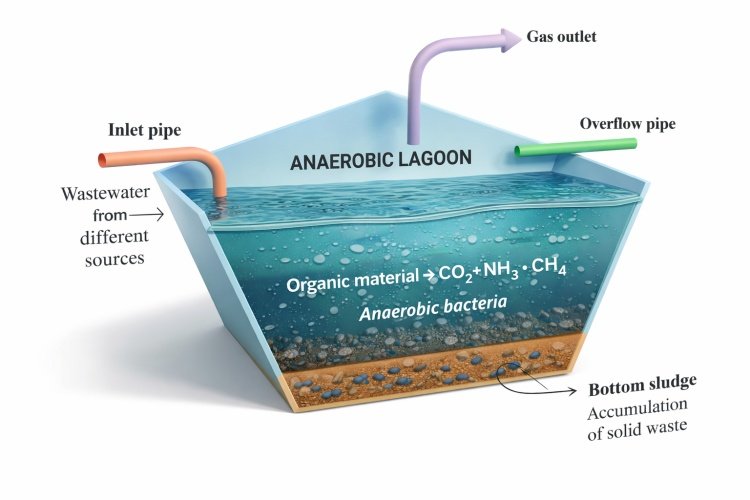

At its core, an anaerobic lagoon is a large, deep, man-made earthen basin designed to treat high-strength organic wastewater in an oxygen-free environment. Think of it as a massive, simplified biological reactor dug into the ground.

The basic components are straightforward:

- The Earthen Structure: An excavated pond, engineered with stable side slopes, provides the volume needed to hold the wastewater.

- The Liner System: A high-performance impermeable barrier, typically a geomembrane, that lines the entire lagoon to prevent wastewater from seeping into the ground and contaminating soil and groundwater.

- The Cover System (Optional): Many modern lagoons include a floating cover to control odors, capture greenhouse gases, and potentially collect biogas for energy.

The primary difference between an anaerobic lagoon and a standard oxidation pond is the absence of oxygen. Anaerobic lagoons are designed to be deep (often 4 to 8 meters) to minimize the surface area exposed to the atmosphere, which naturally creates an oxygen-free (anaerobic) zone at the bottom where the biological treatment occurs. Oxidation ponds, in contrast, are shallow to promote oxygen transfer and aerobic processes.

How Does an Anaerobic Lagoon Work?

While the underlying microbiology is complex, the operational principle of a lagoon is beautifully simple.

Biological Process (High-Level)

Wastewater with high organic content (measured as Chemical Oxygen Demand or COD) is piped into the lagoon. In the dark, oxygen-free environment, specialized anaerobic bacteria go to work. They consume the organic pollutants as their food source, breaking them down through a series of steps.

The primary outputs of this biological process are:

- Treated Effluent: Water with a significantly lower concentration of organic pollutants.

- Biogas: A mixture of methane (CH₄) and carbon dioxide (CO₂), which bubbles up to the surface.

- Sludge: A layer of stabilized organic solids and bacterial biomass that settles at the bottom of the lagoon over many years.

Unlike in a complex mechanical digester, this process happens slowly and naturally within the large volume of the lagoon.

Hydraulic and Operational Characteristics

The key to a lagoon’s success is its massive scale and slow pace. They are characterized by a very long Hydraulic Retention Time (HRT), often ranging from 20 to over 100 days. This means that a water molecule entering the lagoon stays there for a long time, giving the slow-acting anaerobic bacteria plenty of time to do their job.

This "low and slow" approach makes anaerobic lagoons incredibly resilient. They can easily handle large fluctuations in daily inflow volume and organic load, which would overwhelm a smaller, more sensitive high-rate digester. This operational simplicity is one of their greatest strengths.

Key Design Components of an Anaerobic Lagoon

The structure of the lagoon itself is just earth. The performance, safety, and environmental security of the entire system depend entirely on the geosynthetic components designed into it. This is where we, as specialist suppliers, focus our expertise.

4.1 The Liner System (Containment)

The liner is the single most critical component. It is not optional; it is mandatory. An unlined lagoon is not a treatment system; it is a source of groundwater pollution. A liner failure can lead to catastrophic contamination of local aquifers and soil, resulting in enormous environmental liability and cleanup costs.

The industry-standard solution for lining anaerobic lagoons is HDPE (High-Density Polyethylene) geomembrane. Here’s why:

- Exceptional Chemical Resistance: HDPE is inert to the wide range of chemicals, organic acids, and byproducts found in agricultural and industrial wastewater.

- Extremely Low Permeability: It is virtually impermeable, providing a secure barrier against leakage.

- Durability and Longevity: HDPE is highly resistant to UV radiation (during installation) and is engineered to last for decades when properly installed and protected.

For projects in environmentally sensitive areas or with very aggressive waste streams, a composite liner system provides an even higher level of security. This typically consists of an HDPE geomembrane placed over a Revestimiento de arcilla geosintética (GCL). The GCL acts as a self-healing secondary barrier; if the primary geomembrane were ever to be breached, the bentonite clay in the GCL would swell upon contact with moisture, sealing the leak.

4.2 Protective and Cushion Layers

The geomembrane liner is strong, but it is not indestructible. It must be protected from punctures, which can be caused by sharp stones in the subgrade, construction equipment, or debris during cleaning cycles. This protection is provided by a heavy-weight, nonwoven geotextile.

The geotextile acts as a thick, felt-like cushion placed directly underneath the geomembrane. Its job is to absorb and distribute point loads, preventing sharp objects from pressing against the liner and causing a puncture. The condition of the subgrade dictates the required robustness of the geotextile. A lagoon built on a smooth, sandy foundation may only require a medium-weight geotextile, while one built on a rocky or gravelly subgrade will require a very heavy-weight geotextile (e.g., >800 g/m²) to ensure adequate protection. We always advise our clients to see the geotextile not as a cost, but as an insurance policy for the liner.

4.3 Cover Systems

While historically many lagoons were left open to the atmosphere, covered anaerobic lagoons are now becoming the standard for several important reasons:

- Odor Control: Anaerobic processes can produce strong, unpleasant odors. A cover provides near-complete odor containment, which is essential for any facility located near communities or other businesses.

- Greenhouse Gas Reduction: Methane is a potent greenhouse gas. Capturing it prevents its release into the atmosphere.

- Biogas Recovery: The captured biogas can be flared off or, better yet, collected and used as a source of renewable energy to generate heat or electricity for the facility.

The most common solution is a flexible geomembrane floating cover. Made from a durable and UV-stable material like HDPE or LLDPE, the cover floats on the surface of the wastewater, rising and falling with the liquid level. It is fitted with gas vents and collection piping to safely manage the biogas. This turns a waste product (biogas) and a liability (odor) into a potential asset.

Typical Applications of Anaerobic Lagoons

Thanks to their scalability and simplicity, anaerobic lagoons are the workhorses for a wide range of industries that produce high-volume organic wastewater:

- Livestock Farming: They are extremely common for treating swine and dairy manure, which is high in organic content.

- Agriculture and Food Processing: Facilities like slaughterhouses, fruit and vegetable processors, and breweries use lagoons to manage their high-strength wastewater.

- Palm Oil Mills: Anaerobic lagoons are the primary method for treating Palm Oil Mill Effluent (POME), one of the most challenging industrial wastewaters.

- Supplement to Digester Projects: Lagoons are not always a replacement for digesters; they can also support them. They are often used as:

- Digestate storage ponds after initial treatment in a tank.

- Secondary treatment or polishing ponds.

- Large emergency buffer ponds to handle unexpected system upsets or maintenance shutdowns.

Advantages and Limitations of Anaerobic Lagoons

| Ventajas | Limitaciones |

|---|---|

| Low Construction Cost | Large Land Footprint |

| Simple to Operate and Maintain | Lower Treatment Efficiency than Mechanical Digesters |

| Excellent for Large-Scale Treatment | Slower Process, Sensitive to Cold Climates |

| Highly Resilient to Load Fluctuations | Performance is Entirely Dependent on Liner System Integrity |

| Compatible and Enhanced by Geosynthetics | Requires High-Quality Installation and QA/QC |

The key takeaway from this comparison is that while lagoons are simple in concept, their success is not automatic. Their biggest limitation—the complete reliance on the liner system—naturally leads to our most important point.

Why Geosynthetics Are Critical to Anaerobic Lagoon Performance

A concrete anaerobic digester is a structural tank. Its containment is provided by reinforced concrete. An anaerobic lagoon has no inherent structure. It is simply a hole in the ground.

All of its environmental safety, all of its containment function, and all of its long-term reliability depend entirely on the thin layers of geosynthetic materials installed within it.

In anaerobic lagoons, geosynthetics are not accessories—they are the system.

A failure in the design of the liner system, the selection of the wrong material, or poor-quality installation during construction will not just cause a minor problem; it will cause a complete failure of the entire system. This is why working with experienced suppliers and certified installers is not just recommended; it is essential for managing the project's long-term risk.

Conclusion: When Does an Anaerobic Lagoon Make Sense?

An anaerobic lagoon is not a relic of the past. When enhanced with modern geosynthetic materials, it is a sophisticated, reliable, and highly effective wastewater treatment solution. It is the ideal choice for projects that have sufficient land, are sensitive to upfront capital costs, and need to treat large volumes of wastewater with a moderate-to-high organic load.

Instead of viewing them as a "low-tech" alternative to digesters, it's better to see them as a different tool for a different job—or even as a complementary part of a larger, integrated waste management strategy. If these conditions match your project's needs, a properly designed and lined anaerobic lagoon is one of the most robust and economically sound solutions available.