Choosing between two types of non-woven geotextile can be confusing. They look similar, but selecting the wrong one can lead to clogged drains or structural instability, compromising your entire project.

Continuous filament geotextiles are made from long, unbroken fibers, giving them high strength for reinforcement. Staple fiber geotextiles are made from short, entangled fibers, creating a thicker, more permeable fabric perfect for filtration, separation, and drainage. The key difference is strength versus water flow.

Both fall under the "needle-punched non-woven" category, but their internal structure is fundamentally different, creating distinct advantages for specific applications. Understanding this manufacturing difference is the key to selecting a product that performs reliably for the long term. Let's break down how they are made and where each one excels.

How are continuous filament and staple fiber geotextiles manufactured differently?

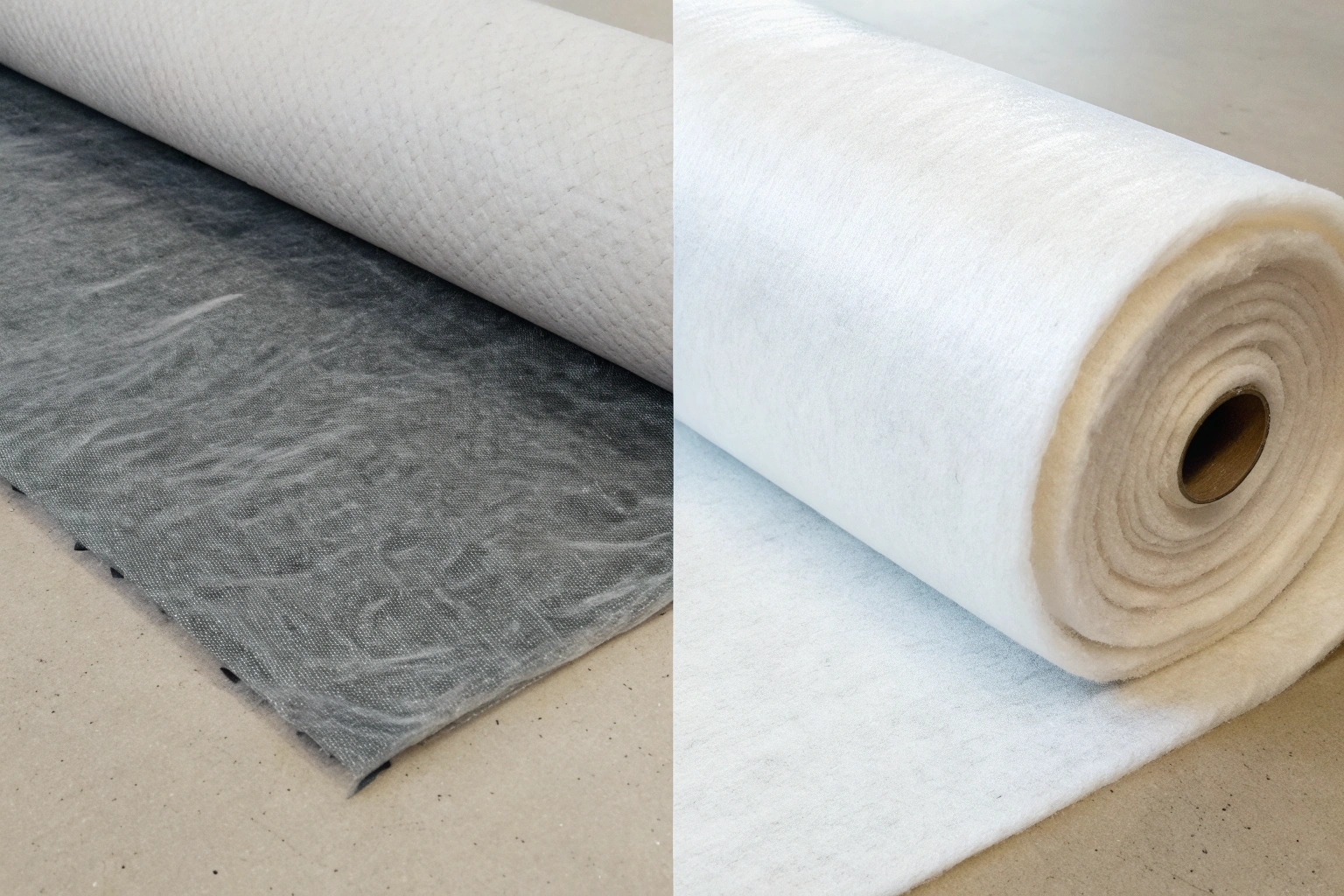

From a distance, they both look like fabric rolls. But this similarity hides a critical difference in manufacturing that dictates their strength, flexibility, and cost, which directly impacts your project's outcome.

Continuous filament geotextiles are produced by extruding long, unbroken strands of polymer (spunbond process) and then needle-punching them. Staple fiber geotextiles are made by taking short, cut fibers, arranging them into a random web (carding process), and then needle-punching them together.

This one difference—long fibers versus short fibers—is responsible for all the performance variations. The continuous filaments create a strong, stable network, while the mass of short fibers creates a thick, porous, sponge-like structure. Visually, continuous filament geotextiles are often whiter with visible long strands, whereas staple fiber types have a more classic, felt-like appearance and can be a darker shade.

What are the main performance differences between the two types?

Relying on weight (g/m²) alone to specify a non-woven geotextile is a common mistake. It doesn't tell you the whole story about strength or water flow, leading to over-speccing or, worse, product failure.

Continuous filament geotextiles offer a superior strength-to-weight ratio and low elongation, making them ideal for reinforcement. Staple fiber geotextiles provide much higher permeability and elongation, excelling at filtration, drainage, and conforming to uneven ground.

The performance trade-off is clear: one provides structural integrity, while the other manages water and offers flexibility.

Performance Head-to-Head

| Performance Metric | Continuous Filament | Staple Fiber |

|---|---|---|

| Tensile Strength | High. Excellent for load bearing and reinforcement. | Lower. Better suited for separation and filtration. |

| Elongation | Low. Provides dimensional stability under load. | High. Flexible and conforms easily to uneven surfaces. |

| Permeability | Lower. Better for separation than high-flow drainage. | High. Allows rapid water flow, ideal for drainage. |

| Thickness | Thinner for a given weight. | Thicker and more cushion-like. |

| Strength-to-Weight | Excellent. More strength from less material. | Standard. |

Which type of needle-punched geotextile is better for my project application?

Knowing the technical differences is one thing, but deploying the wrong type on site can be a costly error. A reinforcement fabric won't drain properly, and a drainage fabric can't provide stability.

Use continuous filament for reinforcement applications like soil stabilization and base course support. Use staple fiber for filtration, drainage, and separation, such as in French drains, behind retaining walls, and as a protective cushion for geomembrane liners.

The choice is always driven by the primary function the geotextile must perform in your design.

Application Guide

| Primary Function | Recommended Type | Why? |

|---|---|---|

| Reinforcement & Support | Continuous Filament | High tensile strength and low creep provide long-term stability. |

| Filtration & Drainage | Staple Fiber | High permeability and forgiving pore structure prevent clogging. |

| Separation | Staple Fiber | A cost-effective way to prevent aggregate and subgrade from mixing. |

| Cushion / Protection | Staple Fiber | Its greater thickness and flexibility protect liners from puncture. |

How can I select the right geotextile to ensure long-term performance and durability?

You've identified the right type, but how do you verify the product you're buying meets your standards? Choosing based on price alone without checking the data sheet can leave you with a material that fails prematurely.

To ensure performance, select a geotextile by matching its Technical Data Sheet (TDS) specifically to your design requirements—tensile strength (kN/m) for reinforcement or permittivity and AOS for filtration. Always source from a supplier who provides complete and verifiable quality documentation.

A professional selection process is data-driven. Don't rely on generic labels; look for the numbers that matter for your specific application.

Key Specification Parameters:

- For Reinforcement: The most critical value is Ultimate Tensile Strength, measured in kilonewtons per meter (kN/m). This defines the fabric's ability to handle load.

- For Filtration: Look for high Permittivity (water flow rate perpendicular to the fabric) and an appropriate Apparent Opening Size (AOS) that matches your site's soil type to prevent clogging.

- For Durability: Consider Puncture Strength and UV Resistance, especially if the material will be exposed during construction.

By providing your project's engineering requirements to a knowledgeable supplier, you can get a recommendation that is not just suitable but optimized for performance and cost.

Conclusion

Choose continuous filament geotextile for strength-driven reinforcement. Choose staple fiber geotextile for filtration- and drainage-driven applications. Matching the manufacturing method to your project's function is the key to success.