Choosing the wrong geogrid can lead to inefficient reinforcement and a wasted budget. Your project demands strength, but is the structural load coming from one direction or from many?

Specify a uniaxial geogrid for high tensile strength in one direction, ideal for retaining walls and slopes. Choose a biaxial geogrid for balanced strength in two perpendicular directions, designed for road base reinforcement and foundation stabilization where loads are multi-directional.

While this core distinction is a great starting point, making a smart sourcing decision requires a deeper understanding of how each geogrid is made and how it performs under load. The wrong choice can lead to over-engineering or, even worse, structural failure. Let's break down the details so you can specify the right material with confidence.

How are biaxial and uniaxial geogrids manufactured and structured differently?

Assuming all plastic grids are made the same can lead to specifying a material that won't handle your project's load requirements. This oversight can compromise structural integrity from day one.

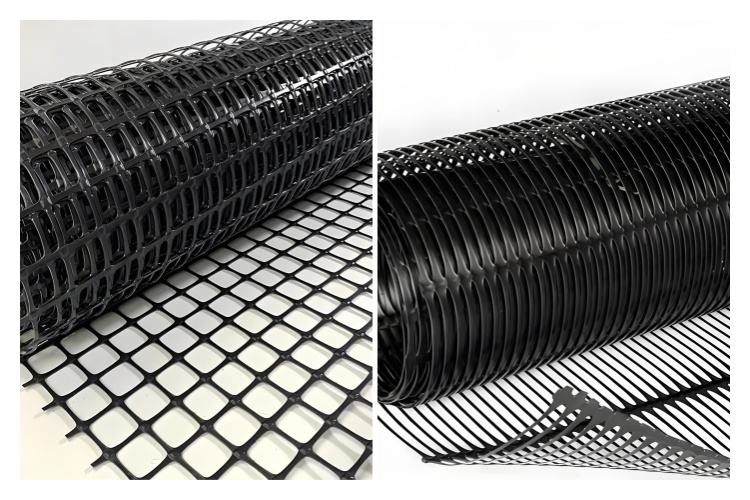

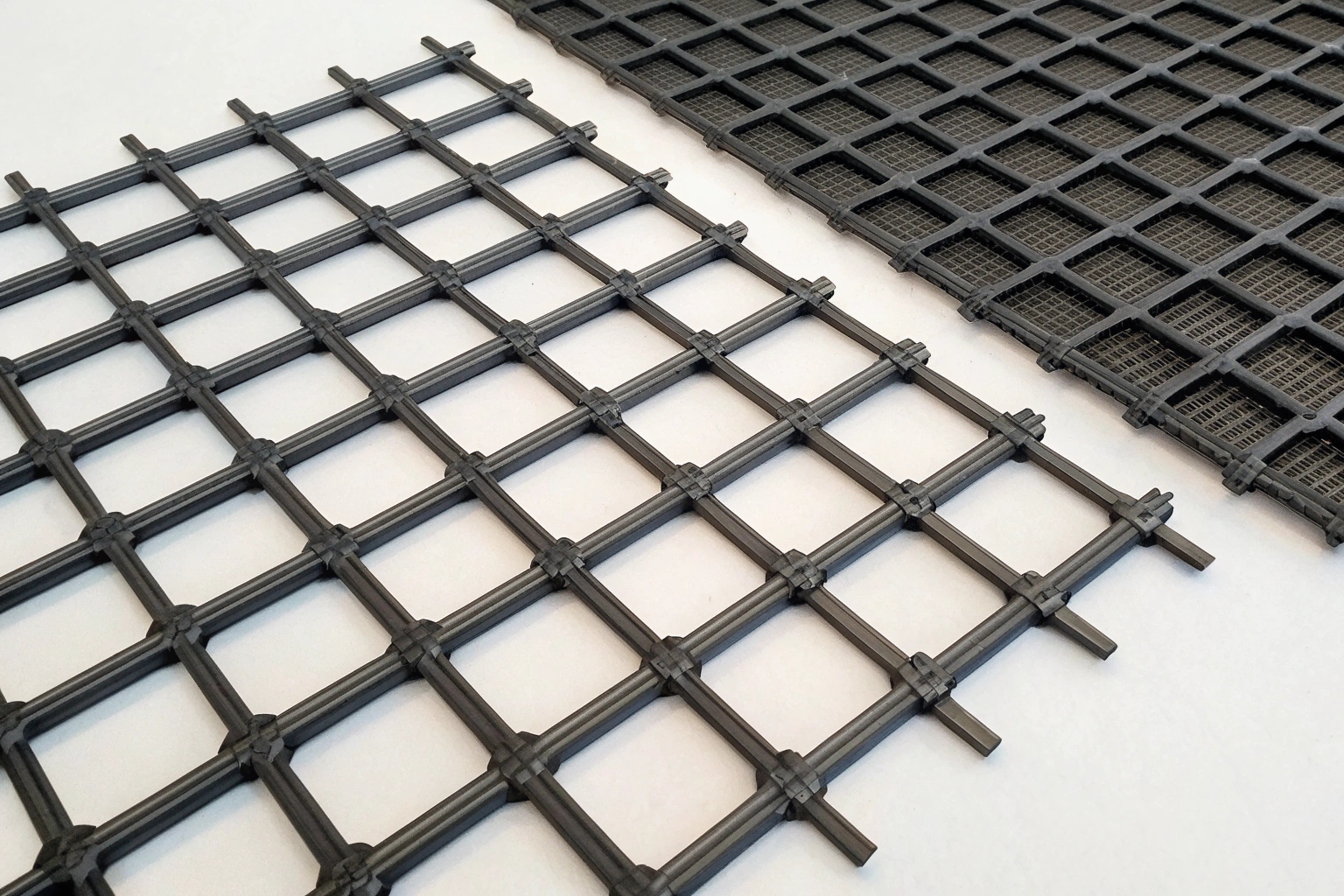

Uniaxial geogrids are made by stretching a polymer sheet in one direction, creating long, strong ribs with maximum strength along a single axis. Biaxial geogrids are stretched in two perpendicular directions, resulting in a square-like grid with balanced strength for multi-directional load transfer.

This difference in manufacturing creates a fundamentally different physical structure. A uniaxial geogrid has thick, powerful ribs in its primary strength direction (the machine direction), with smaller transverse ribs that mainly hold the structure together. Its purpose is to resist sustained tension along a single, predictable line of force.

In contrast, a biaxial geogrid has a uniform, grid-like appearance with square apertures. Its ribs and junctions are engineered to be strong in both the longitudinal and transverse directions. This allows it to effectively interlock with and confine aggregate, distributing dynamic loads over a wider area.

| Feature | Uniaxial Geogrid | Biaxial Geogrid |

|---|---|---|

| Manufacturing | Stretched in one direction | Stretched in two directions |

| Structure | Long ribs in the primary axis | Square grid with strong junctions |

| Strength Focus | Maximized along the roll length | Balanced in two directions |

What performance characteristics distinguish biaxial from uniaxial geogrids?

Looking only at the ultimate tensile strength on a data sheet can be dangerously misleading. This single value ignores critical factors like stiffness and long-term creep, which are vital for project success.

Uniaxial geogrids are defined by their high tensile strength and superior creep resistance along one principal axis, essential for long-term loads. Biaxial geogrids provide balanced stiffness and excellent aggregate confinement in two directions, which is key for reducing deformation under dynamic traffic loads.

Performance directly relates to the intended application. For a retaining wall, the geogrid is subjected to constant tension for decades. Therefore, creep resistance—its ability to resist stretching under a sustained load—is the most critical performance metric for a uniaxial geogrid.

For a road base, the geogrid must withstand repeated, dynamic traffic loads. Its ability to lock aggregate in place (confinement) and distribute stress depends on its **stiffness at low strain and the strength of its junctions in two directions. A biaxial geogrid is engineered for this interlocking and load distribution function. Choosing the grid with the right performance profile ensures the long-term stability and service life of your structure.

Which type of geogrid is better for road base, slope, and retaining wall applications?

Specifying the wrong geogrid type wastes money and risks structural failure. Using a biaxial grid where a uniaxial one is needed is inefficient, and the reverse is often completely ineffective.

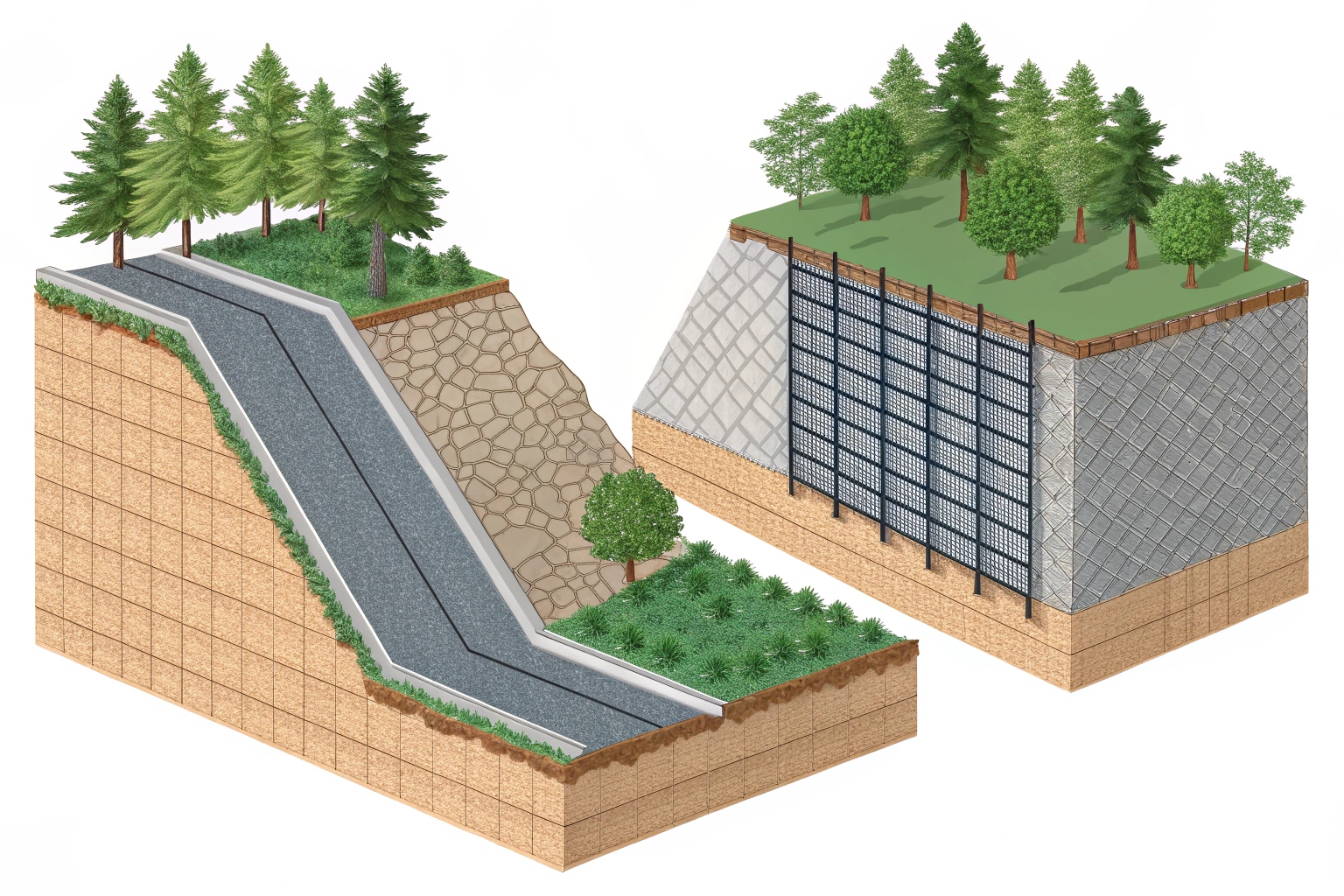

For retaining walls and steep slopes where the main force is in one direction, uniaxial geogrids are the correct choice. For road base reinforcement and foundation stabilization where traffic loads are multi-directional, biaxial geogrids are better suited for effective load distribution.

The application dictates the choice because the direction of the load is fundamentally different for each scenario.

-

Retaining Walls & Slopes: The primary force is gravity pulling soil mass downwards and outwards along a predictable plane. A uniaxial geogrid is installed with its strong axis perpendicular to the wall face to resist this tensile force directly. Using a biaxial grid here means paying for strength in a direction where it is not needed.

-

Road Base & Foundations: Traffic loads from vehicle wheels are dynamic and spread out radially. A biaxial geogrid is essential to interlock with the base aggregate in two directions. This confinement prevents lateral spreading, distributes the load over a wider area of the subgrade, and reduces rutting.

How can I choose the right geogrid type for my engineering design or project?

Unsure which data sheet to request or what to specify in your purchase order? Choosing based on price alone without analyzing the engineering requirements can lead to a costly material mismatch.

To choose correctly, first identify the primary load direction in your project. If the stress is predictable and in one direction (e.g., retaining wall), specify a uniaxial geogrid. If stresses are multi-directional (e.g., road base), specify a biaxial geogrid.

Making the right decision comes down to a simple, functional assessment. Ask yourself one key question: What problem am I trying to solve?

-

Problem: Resisting constant tension in a single plane.

- Applications: Mechanically Stabilized Earth (MSE) walls, reinforced slopes, embankments over soft soils.

- Solution: Uniaxial Geogrid. Your design will specify a required long-term strength based on tensile strength, creep, and durability factors.

-

Problem: Distributing dynamic loads over a wide area.

- Applications: Paved/unpaved roads, parking lots, railway ballast, foundation stabilization.

- Solution: Biaxial Geogrid. Your design will focus on properties like tensile strength at low strain (e.g., 2% or 5%) and junction efficiency, which relate directly to soil confinement and stiffness.

Always refer to your project’s engineering plans and consult the manufacturer’s technical data sheets to ensure the product you source meets the specified performance requirements.

Conclusion

The difference is clear: uniaxial geogrids for one-direction strength in walls and slopes; biaxial geogrids for two-direction strength in roads and foundations. Choose based on your project's load direction.