LLDPE Geomembraan — Vervaardiger, spesifikasies & Oplossing

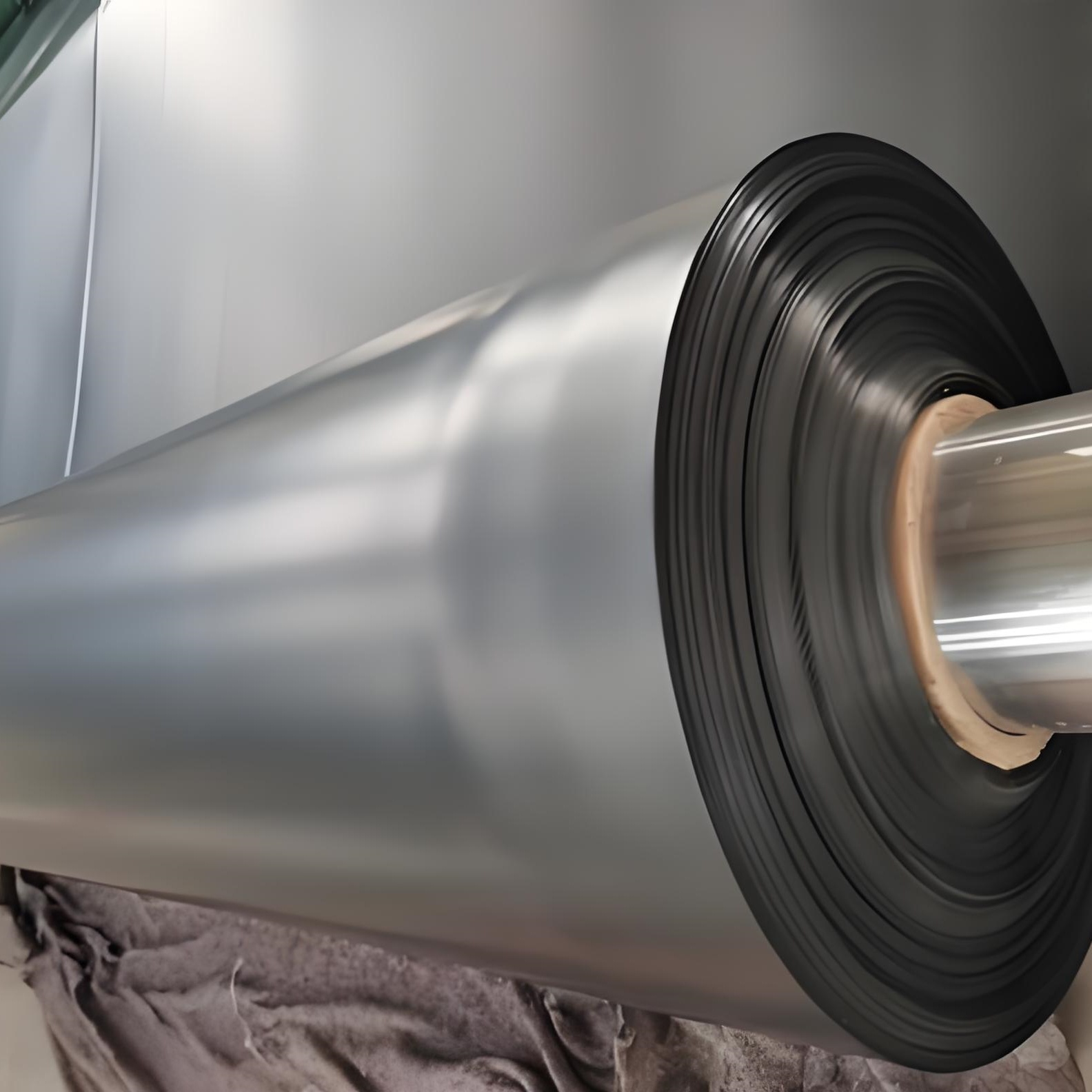

Lineêre lae-digtheid poliëtileen voerings vir damme, kanale en reservoirs. Buigsaam & lekbestand, glad of tekstuur, 0,3–3 mm, fabriek-direkte toevoer en betroubare QA.

ASTM/GRI/ISO-verwysing

Fabriek direk

Uitvoer Global

Kern eienskappe van LLDPE Geomembraan

LLDPE-geomembraan kan oor ongelyke grond strek en by nedersetting of vervorming aanpas sonder om te kraak.

Alhoewel dit effens laer is as HDPE, bied LLDPE steeds voldoende steekweerstand vir damme, kanale en ligte insluitingsprojekte.

Stabiel teen gewone sure, alkalieë en soute, met goeie werkverrigting in buitelugprojekte.

Ideaal vir damme, kanale en hellings waar buigsaamheid meer krities is as treksterkte.

LLDPE bied 'n laer-koste-alternatief vir HDPE vir projekte wat buigsaamheid oor langtermyn hoë-sterkte prestasie vereis.

Leer Ken LLDPE Geomembraan

LLDPE-geomembraan (lineêre lae-digtheid poliëtileenvoering) is 'n buigsame, ondeurdringbare plastiekvel wat gebruik word as 'n versperring vir damme, kanale, reservoirs en ligte stortingsterreinprojekte.

LLDPE-geomembraanmateriaal is gemaak van lineêre lae-digtheid poliëtileen met bygevoegde stabiliseerders. Dit kombineer buigsaamheid, verlenging en chemiese weerstand, wat dit geskik maak vir ongelyke grondtoestande.

Tipiese LLDPE geomembraan dikte wissel van 0.3 mm tot 3.0 mm (200 mikron tot 3,0 mm). Algemene spesifikasies sluit in 0,5 mm, 1,0 mm, 1,5 mm en 2,0 mm, wat in rolle of velle verskaf word.

LLDPE-geomembraan word hoofsaaklik gebruik vir sypel voorkoming en isolasie in 'n wye reeks siviele, omgewings- en waterprojekte, soos:

Vullisterreine en afvalwater/slykbehandelingsterreine (LLDPE-geomembraan vir stortingsterrein)

Rivierdike, damme, uitskotdamme, riooldamme, reservoirs, kanale en vloeibare opgaarputte/myne (LLDPE-geomembraan vir moedervoering)

Metrotonnels, ondergrondse kelders en voering vir ondergrondse strukture

Padbeddings en ander fondamente wat soutweerstand of anti-sypelbeskerming vereis

Horisontale en vertikale sypelversperrings vir damme, kofferdamme en afvalstortingsterreine

Akwakultuur damme vir seewater en varswater vis/garnale boerdery (LLDPE geomembrane dam liner)

Snelweë, snelweë en spoorwegfondasies, as waterdigting lae vir uitgestrekte of opvoubare gronde

LLDPE-geomembraan word gewaardeer vir sy buigsaamheid, aanpasbaarheid by onreëlmatige grond en effektiewe ondeurdringbaarheid, wat dit 'n kostedoeltreffende voering maak vir beide water- en afvalinsluiting.

Die lewensduur van LLDPE-geomembraan is tipies 10-20 jaar, afhangende van dikte, UV-blootstelling en installasietoestande. Vir langtermyn-swaardiensprojekte kan HDPE langer duursaamheid bied.

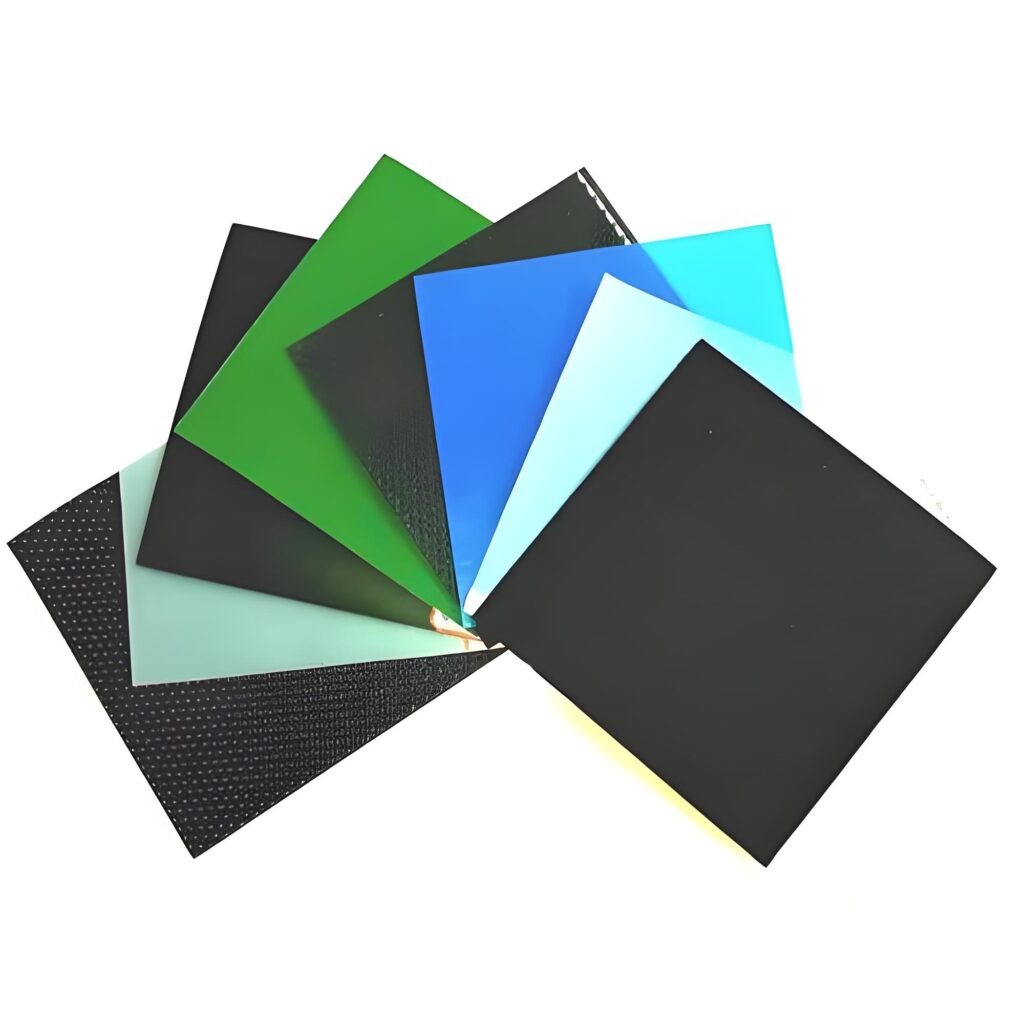

Oppervlaktipes en kleuropsies van LLDPE Geomembraan

Gladde LLDPE Geomembraan

Glad aan beide kante, lae wrywingskoëffisiënt. Maklik om skoon te maak en lekkasie te toets; ideaal vir plat en lae-hellingsprojekte soos reservoirs, kanale en dekoratiewe damme

Enkelsydige tekstuur LLDPE Geomembraan

Een gladde kant, een reliëfkant (kolletjies, diamant of kruispatroon).Verhoog wrywing met grond of deklae; geskik vir ligte tot medium helling antislip toepassings

Dubbelzijdig tekstuur LLDPE Geomembraan

Gebosseleerde tekstuur aan beide kante.Maksimeer wrywing en koppelvlakskuifsterkte; gebruik vir steil hellings, hoë las areas en sywandstabilisering

Swart LLDPE Geomembraan

Die mees algemene keuse, wat koolstofswart bevat om UV-weerstand en verouderingsprestasie te verbeter. Geskik vir alle algemene toepassings teen deursypeling, insluitend damme, kanale en reservoirs.

Blou LLDPE Geomembraan

Verbeter die visuele effek van waterliggame, wyd toegepas in dekoratiewe damme, kunsmatige mere en premium landskapwaterprojekte.

Groen HDPE Geomembraan

Versnit met natuurlike omgewing, geskik vir ekologiese herstel, beskerming van vleilande en landboubesproeiingsprojekte.

Wit LLDPE Geomembraan

Weerkaats sonlig en help om voeringoppervlaktemperatuur te verminder, en verminder plooie wat veroorsaak word deur termiese uitsetting en sametrekking. Dikwels gebruik in tropiese of hoë-temperatuur streke.

LLDPE Geomembraan Dikte Gids & Toepassings

| Dikte (mm) | Sleutelprestasiekenmerke | Tipiese toepassings | Aanbevole spesifikasies en notas |

|---|---|---|---|

| 0.50 mm (200 mikron LLDPE geomembraanplaat) |

• Basiese ondeurdringbaarheid met hoë buigsaamheid • Uitstekende verlenging; voldoen aan fyn grondtoestande |

• Klein ekologiese dammetjies, tuinwaterkenmerke • Plaasgrondbesproeiingsmikrokanale • Seisoenale of tydelike waterberging |

• Gebruik 30–50 g/m² nie-geweefde geotekstielbeskerming • Vermy skerp voorwerpe/swaar meganiese vragte |

| 0.75 mm LLDPE geomembraanrol |

• Verbeterde sypelbeheer • Medium punksie en treksterkte; goeie UV-weerstand |

• Medium-grootte vis & akwakultuur damme (LLDPE geomembraan dam voering) • Landbou-dreineringskanale • Herwonne wateropvangtenks |

• Lê op plat ondergrond • Enkel-tekstuur oppervlak vir hellings < 5° |

| 1,00 mm LLDPE geomembraan |

• Algemene, kostedoeltreffende dikte • Sterk impak- en lekweerstand |

• Besproeiing- en dreineringstelsels • Klein dammetjies vir die versameling van logwater • Munisipale stormwatertenks |

• Glad of enkeltekstuur per wrywingsbehoefte • Add 10 cm sand cushion or geotextile isolation |

| 1.20 mm LLDPE geomembrane liner |

• Higher puncture resistance • Good chemical & aging resistance |

• Sewage treatment pond lining • Basement wall drainage layer • Light-to-medium tailings dam lining |

• Combine with nonwoven geotextile for extra protection • Use textured side toward contact surface to increase friction |

| 1.50 mm LLDPE geomembrane sheet |

• Excellent tensile & puncture performance • Impact and root-penetration resistant |

• Medium landfill lining & capping (LLDPE geomembrane for landfill) • Medium tailings dam liners • Chemical wastewater ponds |

• Prefer double-textured for 5–15° slopes • Leak testing via air-pressure or spark testing |

| 2.00 mm LLDPE geomembraan |

• Engineering-grade thickness • High resistance to puncture, chemical corrosion & aging |

• Large sludge thickening tanks • Hazardous waste secondary containment • Long-term exposed projects in hot/UV-intense climates |

• Pair with high-strength geotextile for multi-layer barrier • Automated welding for stable seams |

| 2.50–3.00 mm LLDPE geomembraan |

• For extreme conditions • Superior puncture, stress-crack & impact resistance |

• Nuclear waste storage • Heavy-metal tailings dams • Deep foundation waterproofing & drainage |

• Multi-layer composite/reinforced structures; professional installation required • Service life can exceed 30+ years |

LLDPE Geomembrane Specifications, Testing & Data Sheet

| Eiendom | Test Method (ref.) | Typical Value / Min | Note |

|---|---|---|---|

| Density | ASTM D1505 | 0.915–0.935 g/cm³ | LLDPE geomembrane density |

| Tensile Properties (yield & break) | ASTM D6693 | Yield ≥ 11 kN/m Break ≥ 16 kN/m |

High elongation; lower yield strength than HDPE |

| Elongation at Break | ASTM D638 | ≥ 600% | Excellent flexibility & deformation capacity |

| Tear Resistance | ASTM D1004 | ≥ 125 N | Good anti-tear property |

| Punksie weerstand | ASTM D4833 | ≥ 160 N | Adequate for ponds & canals |

| Carbon Black Content (black liners) | ASTM D4218 | 2–3% | UV resistance; dispersion per ASTM |

| OIT (Std / HP) | ASTM D3895 / D5885 | ≥ 90 min (Std) ≥ 400 min (HP) |

Oxidative aging resistance |

| Stress Crack Resistance (NCTL) | ASTM D5397 | ≥ 150 hr | Environmental stress cracking performance |

| Dimensional Stability | ASTM D1204 | ±2% | Thermal stability |

| Deurlaatbaarheid | ASTM (as specified) | ≤ 1.0 × 10−13 cm/s | LLDPE impermeable geomembrane |

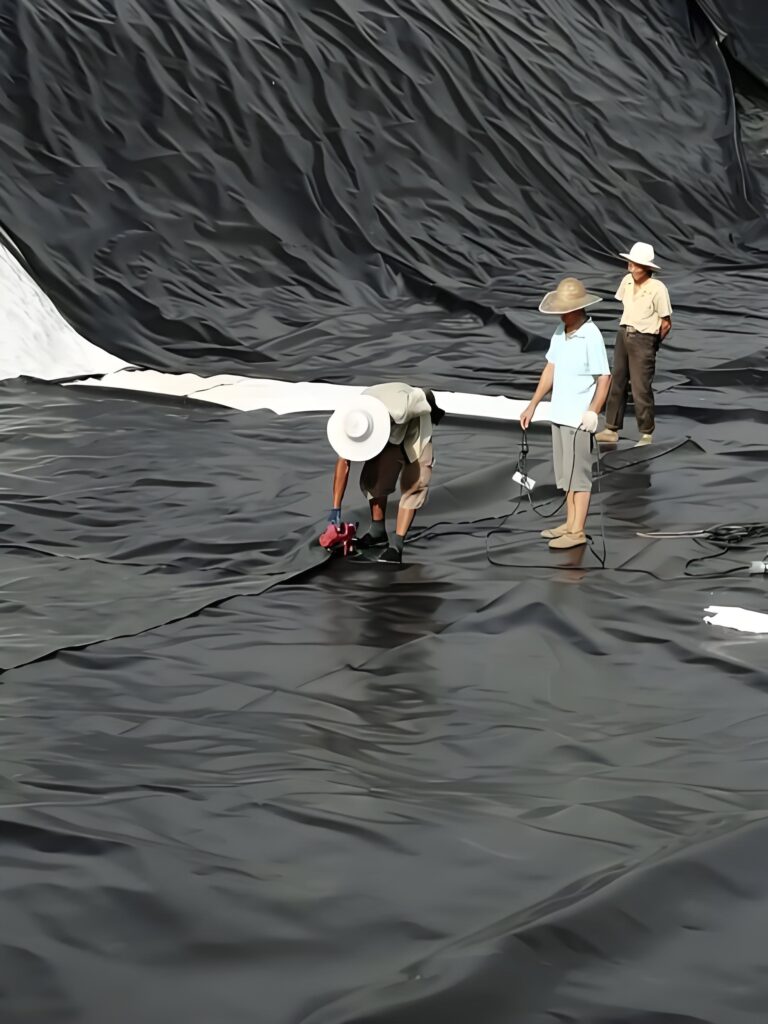

LLDPE Geomembrane Installation,Welding & CQA

Welding Methods

Hot Wedge Welding (Lower Temperature Range): Due to its high flexibility, LLDPE geomembrane requires lower welding temperatures than HDPE, reducing the risk of over-melting. Ideal for long seams in pond liners and canals.

Extrusion Welding for Detail Works: Commonly used for repairs, patching, pipe penetrations, and corner joints. Filler rod welding ensures secure bonding on irregular areas.

Overlap Width: Typically 75–100 mm (less than HDPE) because of the material’s high elongation and ease of fusion.

Quality Control Procedures (CQA)

Trial Welds: Conducted at the beginning of each shift to confirm correct temperature and speed.

Seam Mapping: Visual and mechanical checks to ensure continuous bonding; flexible LLDPE seams are easier to bend and test manually.

Records: Welding logs document machine type, operator, weather, and parameters for traceability.

Testing Methods

Non-Destructive Tests (NDT):

Air Pressure Test: Applied to wedge weld channels to verify seam integrity.

Vacuum Box Test: Used for flat seams, detects leakage points effectively.

Destructive Tests (DT):

Peel & Shear Tests: Samples cut at intervals (every 200–300 m²) and tested per ASTM standards.

For LLDPE, elongation during peel tests is higher than HDPE, reflecting its superior flexibility.

Hoekom kies WP Spesialis?

Over the years, we have established ourselves among trusted LLDPE geomembrane manufacturers and global lldpe geomembrane distributors. Our focus is on delivering reliable liners that meet critical engineering projects.

- Free Samples of LLDPE Geomembrane Sheet

- Kundige projekondersteuning

- Betroubare kwaliteitsversekering

- Meer as 10 jaar se vervaardigingservaring

- Fabrieks direkte voorsiening

Comparison:LLDPE VS LDPE VS HDPE Geomembrane

| Comparison Item | LDPE Geomembrane | LLDPE Geomembraan | HDPE Geomembraan |

|---|---|---|---|

| Molecular Structure & Crystallinity | Highly branched, lowest crystallinity → very soft and flexible | Short side chains, medium crystallinity → balance of strength and flexibility | Straight chain, highest crystallinity → very rigid and strong |

| Density | 0.910–0.925 g/cm³ | 0.915–0.925 g/cm³ | 0.941–0.965 g/cm³ |

| Tensile Strength | 10–20 MPa (lowest) | 20–30 MPa (medium) | 30–40 MPa (highest) |

| Verlenging | ≥ 800% (highest, extremely flexible) | ≥ 700% (very flexible) | ≤ 500% (lower, more rigid) |

| Static Puncture Resistance | Weak, not suitable for sharp subgrades | Moderate, suitable for uneven foundations with some protection | Excellent, rigid structure resists sharp puncture |

| Impact Resistance | Excellent, best energy absorption | Good, combines toughness with impact resistance | Average, prone to micro-cracking under dynamic stress |

| Tear Resistance | Highest, strong crack-arrest property | Good, resists tearing in uneven loads | High tensile but cracks can propagate faster |

| Chemiese weerstand | Good for mild acids/alkalis | Good for general chemical exposure | Excellent, resists strong acids, alkalis, oils, and hazardous chemicals |

| UV Weerstand | Low, needs stabilizers | Good, with carbon black | Excellent, high carbon black → long-term outdoor exposure |

| Temperature Range | -70℃ to +70℃ | -60℃ to +80℃ | -50℃ to +60℃ |

| Algemene dikte | 0.5–2.0 mm | 0.5–3.0 mm | 0.5–3.0 mm |

| Cost Level | Lowest (budget option) | Medium (cost-performance balance) | Highest (premium engineering projects) |

| Tipiese toepassings |

• Light water tanks & indoor liners • Decorative ponds & small landscaping • Temporary anti-seepage covers Recommended when budget is tight and flexibility is key |

• Fish ponds, aquaculture, irrigation canals • Mining site rehabilitation & transport underlayers • Medium waste ponds, dynamic load sites Recommended when you need flexibility + durability balance |

• Municipal landfills, tailings dams • Hazardous waste containment, chemical ponds • Large reservoirs, dam linings, long-term exposure Recommended when long service life & chemical resistance are critical |

| Selection Advice | Choose LDPE if project requires maximum softness and is short-term or light-duty. | Choose LLDPE if project requires adaptability to uneven surfaces en medium service life. | Choose HDPE if project requires highest strength, UV/chemical resistance, en 20+ years durability. |

Basics of Wholesale LLDPE Geomembrane

Please include project type (pond, landfill, mining, reservoir), required thickness, surface (smooth / textured), roll size preference, and delivery terms (FOB/CIF + port).

Yes, free LLDPE geomembrane sheet samples are available for evaluation prior to bulk purchase.

Typical lead time is 15–25 days for production, plus shipping schedule depending on destination port.

The standard roll width for export is 5.8 m, which is optimized for container loading. Longer widths such as 7–8 m are also available, depending on actual container loading conditions. Roll length usually ranges from 50–150 m, adjusted by thickness. Custom prefabricated panels can be supplied if required.

Weight (g/m²) = Thickness (mm) × Density (g/cm³) × 1000.

For LLDPE geomembrane with density 0.915–0.925 g/cm³ (per ASTM D792), a 1.0 mm liner weighs about 915–925 g/m².

Capacity is calculated based on 40HQ ≈ 25 tons loading weight. The exact roll count depends on thickness and roll width; we calculate by the liner weight per m² and container weight limit.

The recommended minimum order is 5000 m². Since geomembrane is bulky and heavy, we suggest at least one 20GP container for efficient shipping. We can also assist in consolidating with other cargo if needed.

We are a China geomembrane manufacturer, and shipments can be arranged from any major Chinese port such as Qingdao, Shanghai, or Ningbo.

Ready to Specify a Geomembrane?

- 15+ jaar van fabriek-direkte kundigheid

- Aangepaste ontwerpte oplossings vir u behoeftes

- Globale aflewering & Logistieke ondersteuning

- 'N deursigtige kwotasie sonder verpligting

- 100% konfdentialiteit gewaarborg

U e -posinligting sal streng van belang wees en ons sakepersoneel sal verseker dat u privaat inligting absoluut veilig is!

Kontak

- info@waterproofspecialist.com

Antwoord binne 12 uur!

Let asseblief op die e -pos met die agtervoegsel “@WaterProofspecialist.com”.