Your project's success depends on a liner that lasts. But UV rays and heat can cause premature aging and failure, leading to costly repairs and environmental disasters.

To improve anti-aging performance, start with a high-quality virgin HDPE resin, add a robust package of carbon black and antioxidants during manufacturing, and protect the installed liner with a soil cover to shield it from UV and thermal stress.

As a manufacturer, I've seen the difference between a geomembrane that lasts for decades and one that fails in just a few years. The secret isn't one single feature; it's a combination of smart choices made at every stage, from the raw material formula to the final installation and maintenance plan. A liner is an investment, and protecting that investment means understanding what makes it durable. Let's walk through the four critical areas where you can significantly boost the anti-aging performance of your HDPE liner.

How can material formulation and resin quality enhance geomembrane aging resistance?

Relying on a liner with a poor formulation is a huge risk. The material will quickly become brittle and crack when exposed to sun and heat, leading to project failure.

Use 100% virgin HDPE resin for maximum molecular integrity. Then, ensure the formula includes 2-3% finely dispersed carbon black for UV protection and a powerful package of antioxidants (like HALS and hindered phenols) to fight thermal degradation.

The Foundation of Durability: Resin and Additives

The battle against aging is won or lost before the geomembrane is even produced. It all starts with the raw material recipe. As a supplier, this is where we have the most control and where quality makes the biggest difference.

-

The Foundation: High-Quality HDPE Resin

The single most important factor is the base resin. I always insist on using 100% virgin HDPE resin for our high-performance liners. Recycled materials can contain impurities and have shorter molecular chains, which makes them much more vulnerable to breaking down over time. A high-density virgin resin provides a stronger, more stable foundation for the entire system. -

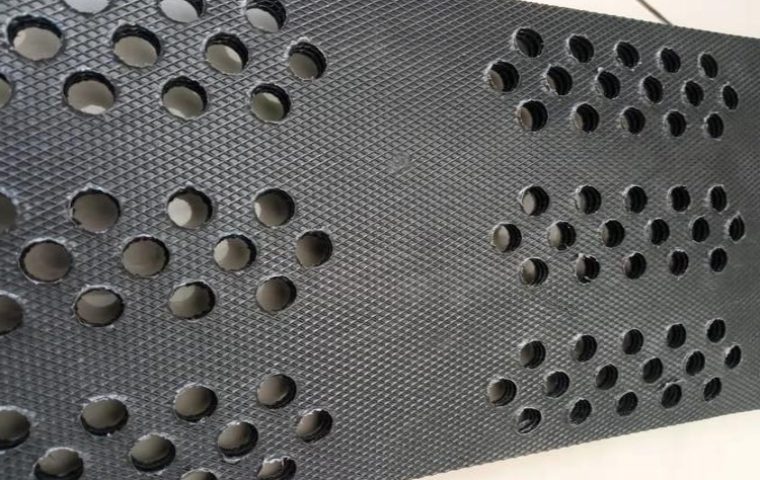

The Additive Shield: Carbon Black and Antioxidants

Next, we build in the protection. Think of these additives as the liner's built-in defense system. Carbon black is the first line of defense, acting as a physical shield against UV radiation. A content of 2% to 3% is the industry standard for a reason—it works. But the real long-term hero is the antioxidant package. This is a blend of special chemicals designed to combat degradation from heat and oxidation.

| Additive Type | Primary Function | Why It's Critical |

|---|---|---|

| Carbon Black | UV Shield | Absorbs damaging UV rays, preventing them from breaking polymer chains. |

| Primary Antioxidants | Free Radical Scavengers | Sacrifice themselves to stop the chain reaction of oxidation caused by heat. |

| Secondary Antioxidants | Peroxide Decomposers | Clean up harmful byproducts of the aging process, helping the primary antioxidants last longer. |

We verify the effectiveness of this package with a key quality control test called the Oxidation Induction Time (OIT). A longer OIT value proves the liner has a strong defense package ready to provide decades of service.

What production and processing techniques help improve long-term stability of HDPE liners?

A great formula can be ruined by a bad production process. If additives are not mixed properly, you get weak spots in the liner that will age and fail much faster.

The most critical technique is ensuring the uniform dispersion of carbon black and antioxidants through advanced screw-mixing technology. Also, manufacturers must strictly control extrusion temperatures to avoid "burning off" the protective additives before the liner is even finished.

From Pellet to Perfect Sheet

After we have the right recipe, we have to cook it correctly. The manufacturing process is where the potential of the raw materials becomes a reality. A cheap or poorly controlled process can create a liner that looks good on the roll but is destined for early failure.

-

Uniform Dispersion is Everything

You can have the perfect amount of carbon black and antioxidants, but if they are clumped together in some areas and absent in others, it's useless. The UV rays and heat will simply attack the unprotected spots. I explain this to clients like trying to bake a cake: if you don't mix the sugar in properly, some bites are bland and others are way too sweet. We use specialized extrusion equipment with advanced mixing screws to guarantee every square inch of the geomembrane has the same level of protection. -

Controlled Extrusion Temperatures

The process of melting the HDPE resin to form a sheet takes a lot of heat. However, too much heat can actually damage the material. If the temperature in the extruder is too high or the material stays in there for too long, it can begin to consume the very antioxidants we added to protect it. A good manufacturer carefully controls the temperature profile along the entire production line to melt the resin properly without degrading it, preserving the full anti-aging potential for its life on-site.

How can engineering design and on-site protection reduce UV and thermal degradation?

Leaving a geomembrane exposed to the elements is the fastest way to destroy it. Sun and heat are relentless, and they will break down even a high-quality liner over time.

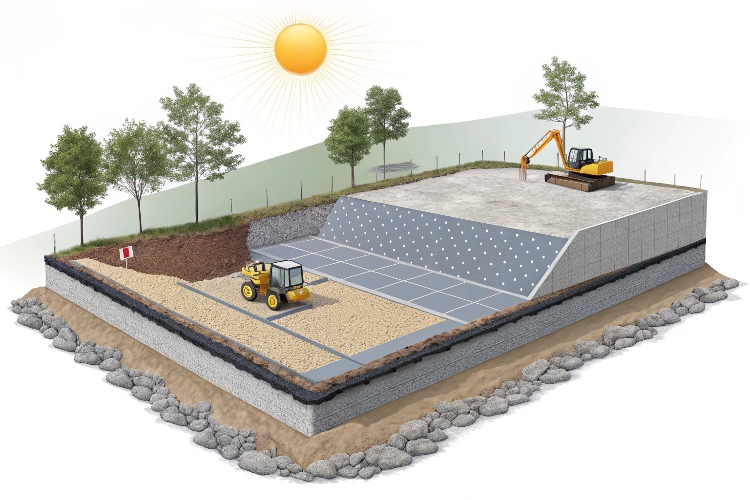

The single most effective strategy is to cover the geomembrane. By burying the liner under at least 30 cm of soil, gravel, or another protective material, you completely shield it from direct UV radiation and buffer it against extreme temperature swings.

Designing for Durability

Once the liner leaves our factory, the responsibility shifts to the project designer and installer. Smart design choices on-site are just as important as the material formulation itself.

-

The Power of a Protective Cover

I cannot stress this enough to my clients: if you can cover the liner, cover it. An exposed geomembrane is in a constant battle with the sun. A buried geomembrane is not. This simple act of covering the liner can extend its functional service life by many decades. Even on steep slopes, using a non-woven geotextile or geomat as a cover is far better than leaving the liner fully exposed. The protection dramatically slows the rate at which antioxidants are consumed. -

Reduce Physical Stressors

Aging isn't just about UV and heat; it's also about physical stress. The design should avoid sharp corners or excessive slopes that put the liner under constant tension. During installation, crews must be careful to avoid punctures, scratches, or dragging the liner over sharp objects. Every point of physical damage is a weak spot where environmental aging can begin to attack the material more aggressively. A smooth, well-prepared subgrade is a critical part of a long-term design.

What monitoring and maintenance practices can extend the service life of HDPE geomembranes?

Adopting a "set it and forget it" mentality after installation is a mistake. A small, repairable puncture can grow into a major leak if it is not found and fixed.

Implement a regular program of visual inspections to check for any signs of damage, especially after storm events or construction activity. For critical applications, plan to take small samples every 5-10 years for lab testing (like OIT tests) to track the liner's health.

Protecting Your Investment for the Long Haul

A geomembrane is a long-term asset, and like any valuable asset, it benefits from a simple but consistent maintenance plan. The goal is to catch small problems before they become big ones.

-

The Value of Regular Inspections

For any exposed geomembrane, someone should be walking the site periodically to look for issues. This includes checking for punctures from equipment or falling rocks, damage from animals, or any signs of tension or pulling at the anchor points. Early detection and repair of a small hole is simple and cheap. Repairing the consequences of a major leak is not. -

Predictive Testing for Critica

For high-stakes projects like landfills or mining sites, a more scientific approach is best. This involves planning to retrieve small samples of the liner at set intervals (e.g., Year 5, Year 10, Year 20). We can then run OIT tests in our lab on these aged samples. The results tell us exactly how much of the antioxidant package has been consumed. This data allows the asset owner to accurately predict the remaining service life and budget for future replacements proactively, rather than reacting to a failure.

Gevolgtrekking

Improving geomembrane life involves quality materials, smart design, and diligent maintenance. This layered defense—from resin to soil cover—ensures long-term project security and a better return on your investment.