Building a road on soft, unstable ground is a nightmare. Trucks get stuck, the subgrade turns to mud, and the expensive aggregate you trucked in disappears into the soil. This leads to constant, costly repairs and a road that fails years ahead of schedule.

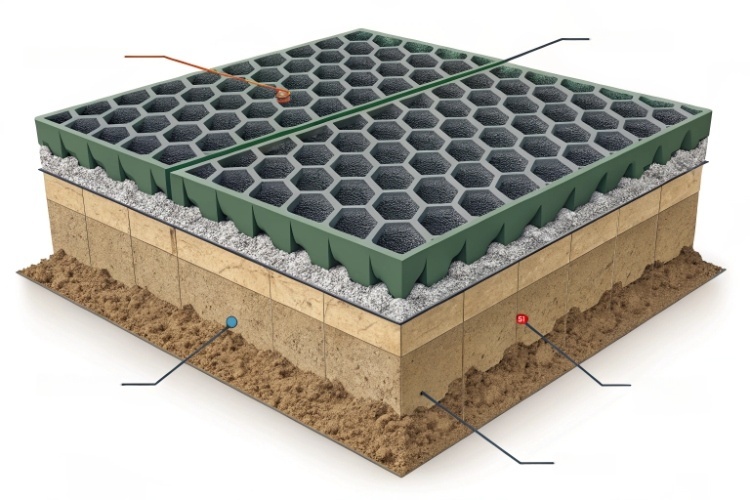

Geocells stabilize roads by creating a 3D honeycomb structure that confines the base material. This cellular confinement distributes heavy loads over a wide area, preventing rutting, reducing the amount of aggregate needed, and drastically cutting down long-term maintenance costs.

As a geosynthetics supplier, I've seen countless projects struggle with weak subgrades. The traditional solution is to excavate and replace tons of soil, which is slow and expensive. Geocells offer a smarter way. They work with the ground, not against it, to create a strong, stable foundation that lasts. Let's dig into how this technology saves you time, money, and headaches.

How do geocells work to reinforce weak or unstable road subgrades?

You're faced with soft, mucky soil that offers almost no support for a new road. The old way means digging it all out and replacing it with good fill, a process that can kill your budget and your schedule.

Geocells reinforce weak subgrades by creating a three-dimensional confinement system. This honeycomb structure locks in aggregate, preventing it from moving sideways and creating a stiff, stable "mattress" that effectively bridges over the soft ground below.

The "Mattress Effect" Explained

The secret to the geocell system is 3D confinement. Think about what happens when a truck drives over loose gravel on soft ground. The gravel just pushes outwards and down, creating a rut. The geocell’s strong, interconnected cell walls stop this from happening. When a load is applied, the cell walls provide tension, holding the infill material in place and forcing it to act as a single, solid slab.

I once worked with a contractor building a temporary access road in a swampy area for a mining operation. Their trucks were getting bogged down daily. Instead of replacing the soil, we recommended they lay down a separation geotextile and then expand geocell panels on top. By doing this, they were able to use locally sourced, lower-quality sand as infill. The geocells increased the bearing capacity of the soft ground by nearly three times. The result? Their trucks could drive smoothly without creating ruts, and they saved a fortune on not having to haul in expensive engineered stone. The system works by:

- Confining the Infill: The cell pockets prevent lateral spreading of the aggregate.

- Increasing Stiffness: By locking the aggregate together, the geocell system creates a semi-rigid slab with a much higher stiffness than the aggregate alone.

- Improving Bearing Capacity: This stiff mattress distributes the load over a wider area, allowing even very weak soils (with a CBR less than 3) to support heavy traffic.

What benefits do geocells provide in distributing loads and preventing rutting?

Your new gravel road looks perfect until the first heavy rain and a few loaded trucks pass over it. Now it's covered in deep ruts that hold water, turning the whole surface into a muddy mess that requires constant grading and repair.

Geocells distribute concentrated wheel loads across a much wider area, reducing the vertical stress on the subgrade. This prevents the soil from deforming under pressure and significantly reduces the formation of ruts, extending the road's functional life for years.

Spreading the Pressure

The science is simple but incredibly effective. A single truck tire applies immense pressure on a very small area. On an unreinforced road, this pressure punches directly into the subgrade, causing it to deform. A geocell system acts like a set of snowshoes, spreading that same weight over an area three to four times larger. This dramatically lowers the pressure at any single point on the weak soil below.

Because the pressure is so much lower, the subgrade doesn't shift or compact unevenly. The result is a massive reduction in rutting—studies show a decrease of up to 18%, depending on the design. This benefit is crucial for both unpaved and paved roads.

- Unpaved Roads: For haul roads or rural access roads, this means the surface stays level and usable without constant grading. You save on fuel, labor, and machinery costs.

- Paved Roads: For roads with an asphalt or concrete surface, preventing rutting in the base layer is even more critical. A stable base means the expensive pavement on top won't crack or settle, which is the main cause of potholes and surface failure.

How do geocell-reinforced roads compare to traditional road bases in durability and maintenance?

Building a traditional road means buying, trucking, and laying a thick layer of expensive, high-quality stone. Even then, it's prone to failure and seems to be under constant repair, consuming your annual maintenance budget with patching and resurfacing.

Geocell-reinforced roads are significantly more durable, extending maintenance intervals from every 5-7 years to as long as 12-15 years. They achieve this by reducing the required aggregate thickness and preventing common failures like rutting, leading to major long-term cost savings.

A Smarter Investment with a Lower Lifecycle Cost

While geocells may add a small amount to the initial construction cost, the return on investment is huge. When I talk to government procurement agents or EPC contractors, we don't just talk about the price per square meter; we talk about the total cost of ownership over 20-30 years.

A geocell system allows engineers to reduce the thickness of the base aggregate layer by 15-25% while achieving the same or better structural performance. That's an immediate, upfront saving on materials and transportation. But the real savings come later. Because the geocell base is so stable and resistant to deformation, the road lasts longer. The numbers are compelling, and this is how they typically break down for a project:

| Feature | Traditional Road Base | Geocell-Reinforced Road Base |

|---|---|---|

| Base Thickness | Requires thick, high-quality aggregate | Reduces aggregate thickness by 15-25% |

| Material Quality | Needs expensive engineered stone | Can use lower-quality, local aggregate |

| Maintenance Cycle | Major repairs typically every 5–7 years | Extends maintenance to every 12–15 years |

| Lifecycle Cost | High due to frequent, costly repairs | Very low, with a cost-benefit ratio of 1.5 to 3 |

For every dollar you spend on a geocell system, you can expect to save up to three dollars over the life of the road by avoiding repairs, material replacement, and traffic downtime.

What factors should be considered when selecting and installing geocells for road stabilization?

You're convinced that geocells are the right solution for your project. But now you see different cell sizes, heights, and panel dimensions. Choosing wrong or installing poorly can compromise the entire system, wasting your investment.

Key factors for selecting geocells include the cell depth, cell opening size, and material seam strength, which must match the expected load and infill material. Proper installation requires a prepared subgrade, correct anchoring, and complete compaction of the infill.

Getting the Details Right

Getting the design and installation correct is straightforward if you focus on the fundamentals. I always guide my clients to consider these points:

Selection Factors:

- Cell Depth (Height): Deeper cells provide greater confinement. For very weak soils or very heavy loads, you'll need deeper cells (e.g., 150mm or 200mm). For firmer ground, a shallower cell (e.g., 100mm) may be sufficient.

- Cell Opening Size: The size of the cell pocket needs to be appropriate for your infill material. A good rule of thumb is that the largest stone in your aggregate should be no more than one-third the size of the cell's diagonal opening.

- Seam Strength: The geocell is only as strong as its welds. The ultrasonic welds that hold the strips together must be strong enough to withstand the stresses of infill and compaction. Always check the manufacturer's data sheet for seam peel strength.

Key Installation Steps:

- Prepare the Subgrade: Create a smooth, level surface. In very soft conditions, lay a nonwoven separation geotextile first.

- Anchor and Stretch: Securely anchor the end of the geocell panel and stretch it to the specified length and width. This is critical; under-stretching the panel results in loose cells and poor confinement.

- Fill the Cells: Fill the cells with your chosen aggregate, slightly overfilling them to account for compaction.

- Compact the Infill: Use a vibratory roller or plate compactor to compact the aggregate within the cells, which locks the entire system together.

Conclusion

Geocells create a mechanically stabilized road base that dramatically improves stability, reduces material needs, and slashes long-term maintenance costs. This makes them a superior investment for any road project on challenging ground, ensuring durability and a higher return over the project's life.