Building a road on soft soil? Without protection, your expensive aggregate base can sink into the mud, and fine soil can pump up, contaminating the structure. This leads to premature failure and costly repairs, compromising your entire project from the ground up.

This guide explains the separation function of geotextiles, a fundamental but critical role they play in civil engineering. We will cover the core principles of how geotextiles prevent soil mixing, where to apply them, and how to select the right material to ensure your infrastructure's long-term stability and performance.

The concept of separation is simple, but its impact on a project's durability is massive. Let's begin by defining exactly what this function entails and why it's a cornerstone of modern construction.

1. Understanding the Separation Function of Geotextiles

So, what is the separation function? In simple terms, it's the use of a geotextile as a barrier to prevent two different types of soil or fill material from mixing. As a supplier, we see this as one of the most common and cost-effective uses for our products. The primary goal is to maintain the original thickness and integrity of each soil layer, which is essential for the structural stability of roads, railways, and embankments.

This function becomes critical when you place a coarse, granular material (like a stone aggregate base) over a fine-grained subgrade (like silt or clay). Without a separator, the two layers will inevitably mix under load and due to water movement. The granular material loses its strength, and the fine soil compromises the drainage.

In this article, we'll explore the mechanism behind this separation, discuss its most important applications, and provide practical guidance on selecting the right geotextile. We'll also look at real-world examples to show how this simple fabric layer can save projects from early failure.

2. How Do Geotextiles Prevent Soil Layers from Mixing?

A geotextile performs separation through a combination of being a physical barrier and a filter. It's not just about placing a sheet between two layers; the fabric's properties are engineered to interact with soil and water in a specific way.

First, the geotextile acts as a physical barrier. It stops the coarse aggregate of a base layer from punching down into the soft subgrade below. At the same time, it prevents the fine particles of the subgrade from "pumping" or migrating upwards into the aggregate, especially under the dynamic loads of traffic.

Second, and just as important, the geotextile must be permeable. It needs to allow water to pass through freely without building up hydrostatic pressure, which could weaken the entire structure. This is where the filtration function comes in. The fabric's pores, defined by its Apparent Opening Size (AOS), are designed to be large enough for water to pass but small enough to retain the fine soil particles. Selecting the correct AOS is crucial to prevent the geotextile from clogging over time—a failure mode known as "blinding."

When properly selected, the geotextile maintains this balance, ensuring both structural separation and hydraulic stability for the life of the project.

3. Why Is Separation Important in Road and Railway Construction?

In road and railway construction, the stability of the foundation is everything. Separation is not just a "nice-to-have"; it's a fundamental requirement for long-term performance, especially over weak or saturated subgrades.

Without a separation layer, several problems will occur. Under the repeated stress of traffic, the fine soil from the subgrade will be forced up into the clean aggregate base. This contamination has two major consequences: it clogs the drainage paths within the aggregate, trapping water, and it reduces the internal friction of the base layer, severely decreasing its load-bearing capacity. At the same time, the aggregate punches down into the subgrade, meaning your engineered base layer becomes thinner and less effective than designed.

The result is a cascade of failures: the road or railway develops ruts, differential settlement occurs, and the surface cracks. These issues lead to a much shorter service life and require frequent, expensive maintenance. By investing in a simple geotextile separation layer, you preserve the full thickness and strength of your base course. This can extend the infrastructure's service life by 15–25% and dramatically reduce lifelong maintenance costs. It's one of the highest-return investments you can make in a transportation project.

4. Where Are Geotextile Separation Layers Commonly Used?

The separation function is versatile, and we supply geotextiles for this purpose across a wide range of civil engineering applications. While roads are the most common use, the principle applies anywhere you need to maintain the integrity of adjacent soil or fill layers.

Common Applications

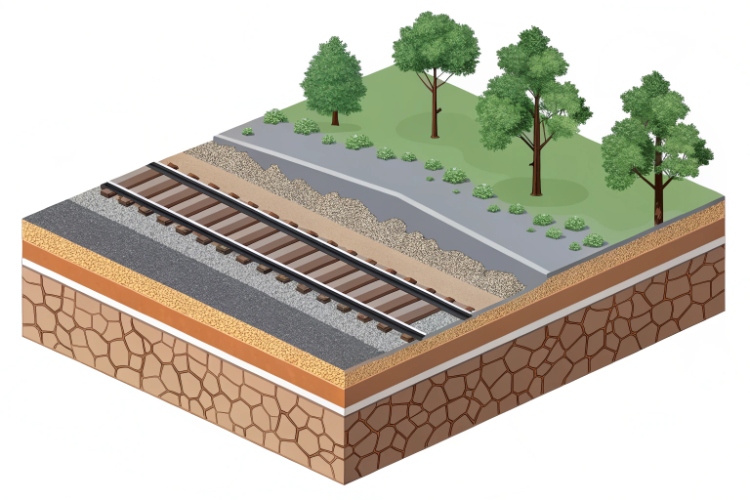

- Roads and Pavements: Placed between the subgrade soil and the stone aggregate base course to prevent mixing and preserve structural capacity. This includes everything from unpaved access roads to major highways.

- Railway Trackbeds: Installed below the ballast layer to prevent fine subgrade soils from contaminating the ballast. Clean ballast is essential for drainage and track geometry, so separation directly impacts railway safety and maintenance cycles.

- Parking Lots and Airport Runways: Similar to roads, these large paved areas rely on a stable base to handle vehicle loads. Geotextile separators prevent settlement and rutting in parking areas and ensure the structural integrity of high-stress runways.

- Embankments and Earth Dams: Used to separate different fill materials within an embankment, ensuring each layer performs its intended function (e.g., separating a free-draining rockfill from a clay core).

- Landfill and Drainage Systems: In landfills, separators prevent fine waste particles from clogging drainage layers. In French drains or other subsurface drainage systems, they wrap around the drainage aggregate to stop surrounding soil from silting up the system.

In each scenario, the geotextile stops intermixing, allowing each layer of the engineered system to function as designed.

5. What Factors Should Be Considered When Selecting a Geotextile for Separation?

Choosing the right geotextile for separation involves more than just picking a fabric. You must match its properties to the soil conditions, expected loads, and installation stresses. Here are the key factors we advise our clients to consider.

Material Type: Woven vs. Nonwoven

The choice between a woven and a nonwoven geotextile is a primary consideration.

- Woven Geotextiles are generally preferred for separation combined with reinforcement due to their high tensile strength and low elongation. They provide excellent resistance to aggregate punching down.

- Nonwoven Geotextiles excel in applications where superior permeability and filtration are critical. Their felt-like structure offers excellent water flow and soil retention properties.

| Feature | Woven Geotextile | Nonwoven Geotextile | Notes for Separation |

|---|---|---|---|

| Primary Function | Separation & Reinforcement | Separation & Filtration | Choose woven for high-stress roads; nonwoven for drainage. |

| Tensile Strength | High (e.g., 20-120 kN/m) | Moderate (e.g., 8-30 kN/m) | Higher strength resists installation damage. |

| Permeability | Moderate | High | Nonwovens are better for preventing water pressure buildup. |

| Typical Grammage | 300-500 g/m² | 150-300 g/m² | Heavier fabrics offer more robustness and puncture resistance. |

Key Performance Properties

- Strength: The geotextile must be strong enough to survive installation. Puncture resistance and tear strength are critical, as any damage during construction will compromise the separation function.

- Permeability & AOS: As discussed, the fabric must allow water through while retaining soil particles. This requires careful matching of the geotextile's Apparent Opening Size (AOS) with the particle size distribution of the subgrade soil.

- Durability: The fabric must be resistant to UV degradation (during installation) and chemically stable in the specific soil environment.

Installation Requirements

Proper installation is just as important as material selection. Make sure to specify and enforce correct overlap distances—typically between 300 mm and 1 meter, depending on the subgrade strength. Inadequate overlaps create weak points where soil mixing can occur, defeating the purpose of the geotextile. The fabric must also be anchored securely and protected from damage by construction equipment.

6. What Problems Occur Without Proper Geotextile Separation?

Failing to use a separation geotextile on a vulnerable site isn't a shortcut; it's a recipe for structural failure. We've seen projects where skipping this step has led to a need for complete reconstruction within a few years. The problems that arise are predictable and severe.

First, you get subgrade contamination. Fine soil particles from the subgrade move up into the aggregate base layer. This reduces the base's drainage capacity, trapping water and weakening the foundation, especially during freeze-thaw cycles which can cause soil heaving.

Second, the structural system loses its load-bearing capacity. The aggregate base, now contaminated and often thinner because it has punched into the subgrade, can no longer distribute loads effectively. This leads directly to rutting and differential settlement on the surface of the road, railway, or parking lot. These surface defects are not just cosmetic; they indicate a failing foundation.

Ultimately, these issues result in a drastically shortened service life and sky-high long-term maintenance costs. What might have been saved by omitting a geotextile is spent many times over on patching, overlays, and eventually, full-depth reconstruction. Proper separation prevents these problems from ever starting.

7. How Has Geotextile Separation Improved Real Projects?

The benefits of geotextile separation are not just theoretical; we see them in practice on projects all the time. Let me share a typical example that illustrates the impact.

We recently supplied a project for an access road to a new industrial park. The site was challenging, with a soft, clay-heavy subgrade (low CBR value). The original design called for a very thick aggregate base of 500 mm to compensate for the weak ground. The contractor was concerned about the high cost of quarrying and transporting that much stone.

We proposed an alternative: using a high-strength woven geotextile for separation and reinforcement. By placing our geotextile directly on the prepared subgrade, we could guarantee the integrity of the base course. The geotextile prevented the clay from contaminating the aggregate and distributed the traffic loads more effectively.

The revised design, approved by the project engineer, allowed the aggregate base thickness to be reduced to just 350 mm—a 30% reduction. This resulted in immediate and substantial cost savings on materials and transportation. Furthermore, the construction was faster because less excavation and filling were needed. The road has now been in service for several years with no signs of rutting or settlement, and its projected service life is significantly longer than would have been possible without the geotextile.

Conclusion

The separation function of a geotextile is a simple yet powerful tool for ensuring the long-term stability of civil engineering projects. By preventing the mixing of soil layers, it preserves the designed strength and drainage characteristics of your infrastructure foundation. This single layer of fabric directly combats rutting, settlement, and premature failure, translating into significant cost savings and a longer, more reliable service life for roads, railways, and more.