Geosynthetic Clay Liner (GCL) Manufacturer & Global Supply

Engineered GCL liners using natural sodium bentonite for reliable waterproofing in landfill, reservoir, and mining projects.

Ultra-Low Permeability

Self-Sealing Waterproofing

Long Service Life

Get to Know GCL

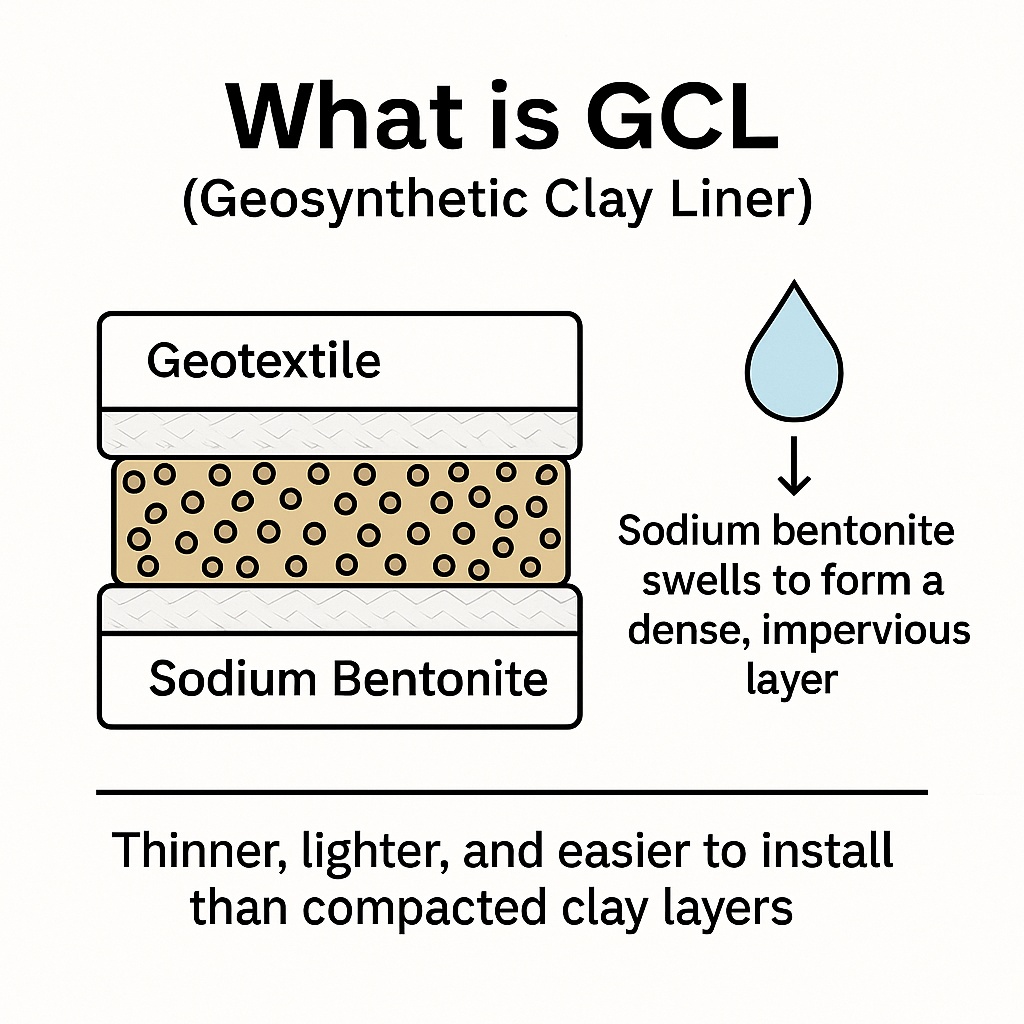

A Geosynthetic Clay Liner (GCL) is a composite waterproofing material made of natural sodium bentonite enclosed between geotextile fabrics or geomembranes. When hydrated, it forms a dense, self-sealing barrier that replaces thick compacted clay layers in modern environmental and civil engineering projects. systems.

GCL works through the swelling behavior of sodium bentonite. When water enters, the clay expands to fill voids and forms a low-permeability gel-like layer. This creates a continuous hydraulic barrier that prevents liquid migration while maintaining flexibility to adapt to ground movement or settlement.

Geosynthetic Clay Liners are used for waterproofing and containment in landfills, reservoirs, artificial lakes, mining leach pads, and underground structures. Their self-healing property and simple installation make them ideal for sustainable, long-term seepage control in environmental and civil engineering projects.

Most GCLs range from 4.5 mm to 6.5 mm thick, depending on bentonite content and structure. Despite being much thinner than compacted clay layers (often 300–600 mm), a GCL provides equal or superior impermeability with hydraulic conductivity as low as 1×10⁻¹¹ m/s.

GCLs are mainly classified by structure and bonding method:

GCL-NP – Needle-punched type using two geotextiles and bentonite core.

GCL-OF – Needle-punched with HDPE film for dual protection.

GCL-AH – Adhesive type bonding bentonite to polyethylene plate.

Some variants include salt-resistant or reinforced GCLs for harsh conditions.

GCL Structure & Working Principle

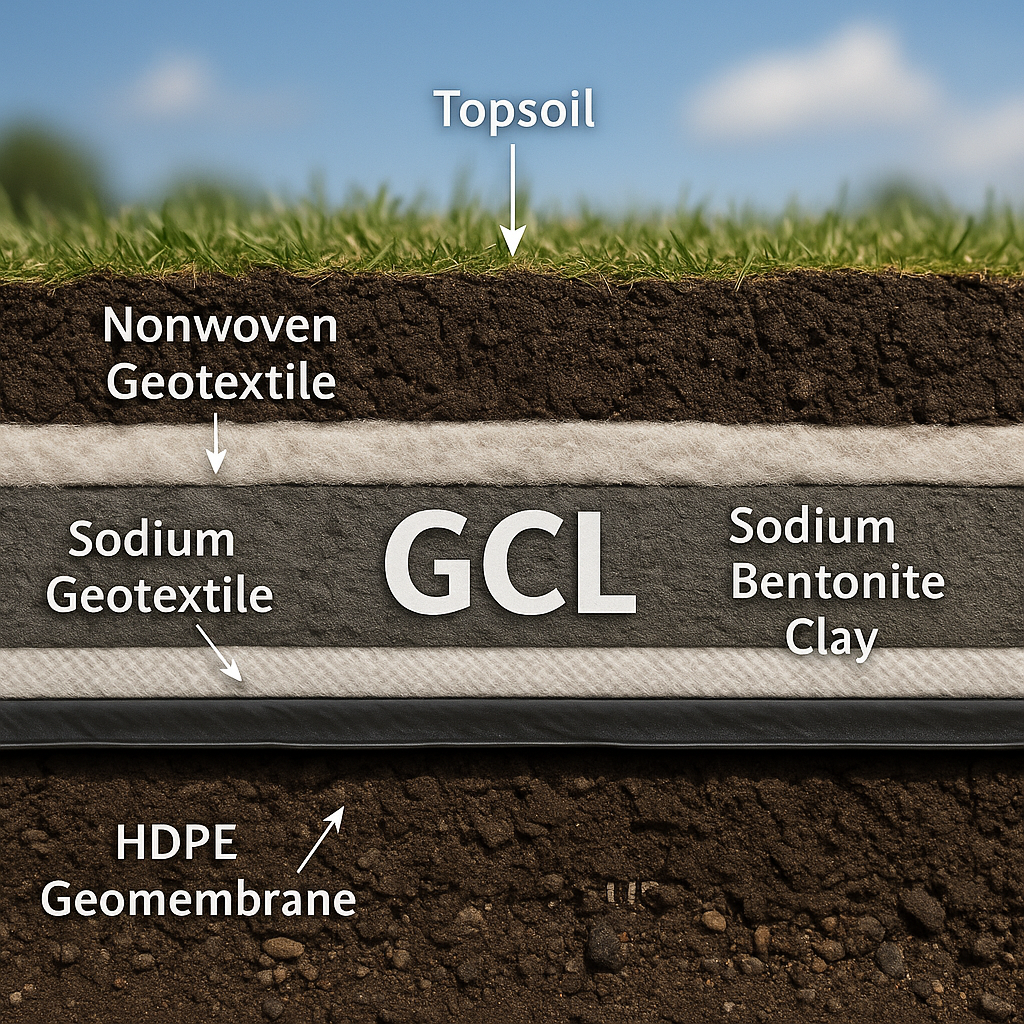

Topsoil Cover Layer

This surface layer provides physical protection for the waterproofing system. It prevents drying, limits UV exposure, and helps maintain the overall integrity of the GCL installation.

Upper Nonwoven Geotextile

The upper geotextile acts as a protection and reinforcement layer. It encapsulates the bentonite core and provides tensile strength, filtration capacity, and flexibility during installation.

Sodium Bentonite Core (GCL Layer)

The central bentonite layer is the active waterproofing element. When hydrated, the sodium bentonite swells to form a dense, self-sealing, and extremely low-permeability barrier—blocking liquid migration and sealing minor punctures.

Lower Geotextile + HDPE Geomembrane Composite

The woven geotextile adds structural stability, while the HDPE geomembrane enhances chemical resistance and long-term impermeability, especially under harsh environmental conditions.

Working Principle:

When water reaches the bentonite core, it hydrates and expands, filling voids and creating a continuous impermeable gel layer that prevents seepage.

Classification & Models of GCL

Different types of Geosynthetic Clay Liners (GCL) are designed to meet various project requirements.

The tables below summarize the main production types, bentonite compositions, and performance enhancements, helping you choose the most suitable GCL model for your environmental or engineering application.

| Type | Structure Description | Key Features | Typical Applications |

|---|---|---|---|

| GCL-NP (Needle-Punched GCL) |

Two geotextile layers encapsulating natural sodium bentonite through needle punching | Excellent flexibility, self-healing, and easy installation | Landfill base liners, reservoirs, tunnels, and subgrade waterproofing |

| GCL-OF (Needle-Punched + HDPE Film) |

Same as GCL-NP but laminated with HDPE geomembrane on one side | Dual waterproof protection, high chemical resistance, puncture resistance | Hazardous waste landfills, leach pads, chemical containment ponds |

| GCL-AH (Adhesive Type) |

Bentonite bonded to polyethylene sheet using adhesive compaction | Ultra-low permeability, dense structure, zero-leakage performance | Nuclear waste disposal, industrial chemical ponds |

| Type / Enhancement | Characteristics | Recommended Applications |

|---|---|---|

| Natural Sodium Bentonite (N Type) | High swelling index ≥ 24 ml/2g, strong self-sealing capacity | Drinking water reservoirs, ecological projects |

| Artificially Sodium-Activated (A Type) | Modified calcium bentonite, lower cost alternative | Roof gardens, underground garages, retaining walls |

| Salt-Resistant GCL | Stable impermeability in saline or electrolyte water | Coastal works, wastewater treatment ponds |

| Reinforced GCL | Higher bentonite content or stronger geotextiles for high-load conditions | Subway tunnels, hydraulic dams, mining tailings areas |

GCL Solutions for Different Engineering Projects

GCL-OF

GCL-NP

GCL-AH

Reinforced GCL

GCL Testing Standards & Performance Data Sheet

| Test Item | Purpose / Description | ASTM Standard | Typical Range / Note |

|---|---|---|---|

| Swell Index of Bentonite | Measures the expansion capacity of sodium bentonite in water, indicating sealing performance. | ASTM D5890 | ≥ 24 ml/2g |

| Fluid Loss of Bentonite | Evaluates the retention ability of bentonite slurry; smaller values mean better impermeability. | ASTM D5891 | ≤ 18 ml |

| Permeability / Hydraulic Conductivity | Determines how well GCL resists water seepage under pressure. | ASTM D5084 / D5887 | ≤ 5×10⁻¹¹ cm/s |

| Index Flux Through GCL | Measures the flow rate of water through the GCL under a constant head. | ASTM D5887 | ≤ 1×10⁻⁸ m³/m²/s |

| Peel Strength / Internal Bond Strength | Tests the bonding strength between geotextiles and the bentonite layer. | ASTM D6496 | ≥ 40 N/100 mm |

| Tensile Strength & Elongation | Assesses tensile resistance and flexibility of the composite geotextiles. | ASTM D4632 / D4595 | ≥ 600 N/100 mm |

| Mass per Unit Area | Determines the total mass of GCL (g/m²), indicating bentonite content. | ASTM D5993 | 4000–6000 g/m² |

| Index Flux & Hydraulic Conductivity of GCLs | Measures combined hydraulic performance under confining stress. | ASTM D5887 | Confirm impermeability under site pressure |

| Shear Strength (Internal / Interface) | Evaluates internal shear or interfacial friction between GCL and subgrade. | ASTM D6243 | Project-specific design value |

| Thickness Measurement | Measures GCL thickness under standard load. | ASTM D5199 | Typically 4.5 – 7 mm |

| Durability / Chemical Resistance | Determines stability in chemical or saline environments. | ASTM D6141 | Pass / No visible degradation |

Advantages & Key Features of GCL

Sodium bentonite forms a high-density impermeable barrier under water pressure.

It has strong self-retaining water capacity and achieves ultra-low permeability (≤5×10⁻¹¹ cm/s), preventing leakage even under long-term hydraulic load.

As a natural inorganic mineral, sodium bentonite does not age, corrode, or decompose.

Its waterproofing ability remains stable for decades, unaffected by environmental changes — ideal for landfills, reservoirs, and tunnels requiring lifetime durability.

Unlike membranes requiring heat welding or adhesives, GCL installation is straightforward.

Simply overlap and fix with nails, washers, or bentonite powder, and it seals naturally after hydration.

No special surface treatment is needed, and any defects can be easily repaired.

GCL offers the shortest construction time among waterproof materials.

GCL remains flexible even under freezing conditions.

It does not become brittle or crack, ensuring continuous waterproofing in cold or alpine climates.

When hydrated, sodium bentonite expands 20–28 times its original volume.

This swelling allows it to fill voids and repair microcracks up to 2 mm in concrete or soil structures.

Even under vibration or settlement, GCL maintains tight integration with the structure.

Made from natural, non-toxic bentonite, GCL is completely safe for humans and ecosystems.

It has no volatile emissions or chemical additives, making it an ideal choice for ecological restoration projects, wetlands, and drinking water reservoirs.

Performance Highlight:

Permeability as low as 5×10⁻¹¹ cm/s — up to 100× better than compacted clay liners.

Customization options of GCL

| Customizable Item | Available Options / Range | Notes |

|---|---|---|

| Unit Weight (Mass per Area) | 4000 – 6500 g/m² | Adjust bentonite content to meet impermeability requirements. |

| Bentonite Type | Natural Sodium / Activated Sodium / Salt-Resistant Formulation | Choose according to water quality and chemical composition. |

| Structure Type | Needle-Punched (NP) / HDPE Film Coated (OF) / Adhesive Bonded (AH) / Reinforced Type | Multiple configurations available for different sealing grades. |

| Thickness | 4.5 – 7 mm (Standard), up to 10 mm (Reinforced) | Increased thickness improves mechanical and puncture strength. |

| Roll Width & Length | Width: 1–6 m / Length: 20–40 m per roll | Wider rolls reduce on-site joints and installation time. |

| Geotextile Material | PP / PET Nonwoven + Woven Fabric | Available with UV or oxidation-resistant finish. |

| Surface Film | Single or Double-Sided HDPE / LDPE / EVOH Film | Enhances chemical resistance and durability under pressure. |

| Packaging & Label | PE-wrapped rolls, palletized or bulk loading | OEM logo, export label and barcoding available upon request. |

| Testing Standard | JG/T193-2006 / ASTM / ISO / GRI | QC reports and COA supplied with each shipment. |

GCL Installation Method

Proper installation is essential to ensure the long-term sealing performance of a GCL.The following points summarize standard procedures used in landfill, reservoir, and foundation waterproofing projects.

Subgrade preparation

Ensure the subgrade is smooth, compacted, and free of sharp stones, roots, or debris.

Recommended slope gradient: ≤ 1:3 for stable placement.

Liner placement

Unroll GCL panels carefully in the same direction as the layout.

Avoid dragging across the ground to prevent tearing of geotextiles.

Overlap and seaming

Typical overlaps should be 300 mm on both longitudinal and transverse joints.

Apply bentonite powder or granules evenly along the overlap to enhance sealing.

Fixing and anchorage

On slopes, fix the GCL using nails and washers or anchor trenches at crest and toe.

For vertical surfaces, mechanical fasteners or shotcrete can be used.

Protection layer

Cover immediately after installation with soil, sand, or a geotextile cushion layer to prevent UV exposure and dehydration.

Avoid direct contact with heavy machinery.

Weather conditions

Do not install during heavy rain, snow, or high winds.

If the GCL becomes hydrated before covering, remove and replace the affected sections.

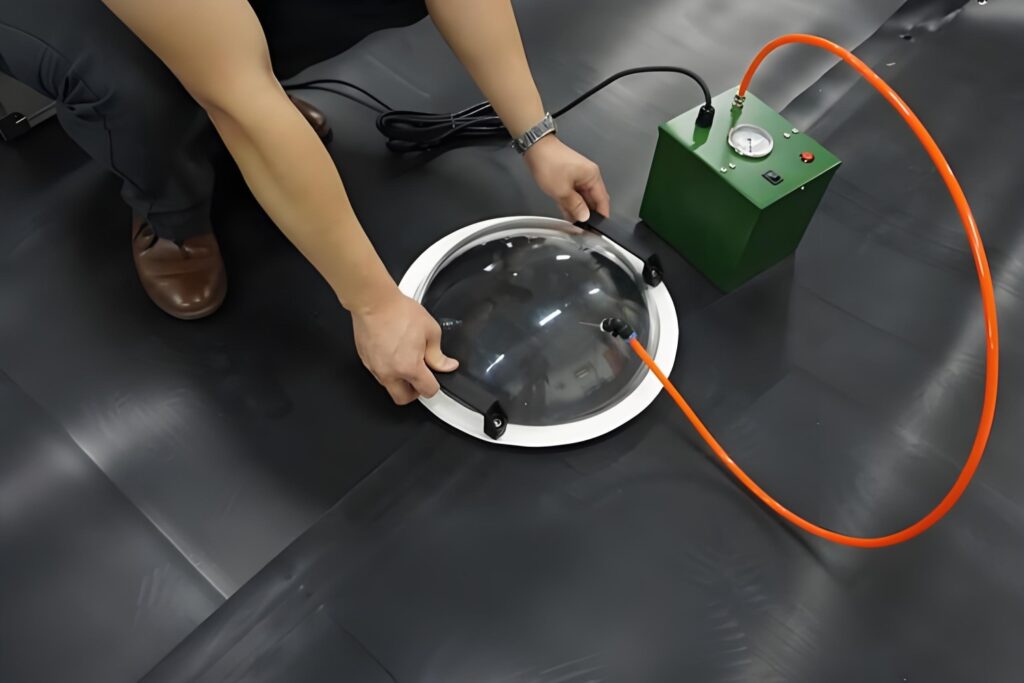

Installation should follow ASTM D5888 or project-specific QA/QC procedures.

Each roll must be checked for identification label, surface damage, and bentonite uniformity before deployment.

Why Choose WP Specialist?

Over the years, WP Specialist has become one of China’s reliable manufacturers and global exporters of Geosynthetic Clay Liner (GCL) products.

Our factory supplies high-performance bentonite waterproof blankets that meet the strict requirements of landfill, reservoir, subway, and foundation waterproofing projects worldwide.

We focus on producing engineered GCLs with consistent bentonite quality, stable impermeability, and long-term durability — fully compliant with ASTM D5887, D5890, and D6243 testing standards.

All products are backed by factory-direct pricing, technical support, and customized solutions for different site conditions.

- Free Samples of Geosynthetic Clay Liner

- Expert Project Support

- Reliable Quality Assurance

- Over 10 Years of Manufacturing Experience

- Factory Direct Supply

Standards & Quality Control

Our Geosynthetic Clay Liners (GCLs) are manufactured and tested with strict reference to internationally recognized standards such as ASTM, GRI, and ISO.

Each roll is produced under controlled conditions to ensure consistent bentonite quality, impermeability, and bonding strength.

Testing scope includes swell index, fluid loss, hydraulic conductivity, peel strength, and internal shear resistance, following ASTM methods D5890, D5891, D5887, D6496, and D6243.

Comprehensive inspection is carried out for bentonite distribution, mass per unit area, and moisture content before shipment.

If your project requires compliance with specific international or national standards, WP Specialist can customize production and testing protocols accordingly.

Third-party verification and factory audits are always welcomed to ensure transparency and quality assurance.

Why Work With Us

Stable quality control with reliable lead times worldwide.

Third-party test reports and traceable QA records included.

Design guidance, on-site or remote support, and after-sales.

Ready to Specify a GCL?

- 15+ Years of Factory-Direct Expertise

- Custom-Engineered Solutions for Your Needs

- Global Shipping & Logistics Support

- A Transparent, No-Obligation Quote

- 100% Confidentiality Guaranteed

Your email information will be kept strictly confidential and our business staff will ensurethat your private information is absolutely safe!

Contact

- info@waterproofspecialist.com

Reply within 12 hours!

Please pay attention to the email with the suffix “@waterproofspecialist.com”.