Non-Woven Geotextile — China Manufacturer & Technical Specifications

Factory-direct nonwoven geotextile supplier from China. PET and PP needle-punched non woven fabrics for separation, filtration, and drainage in civil engineering.

Export Global

Factory Directly

Certified Quality

Properties of Non Woven Geotextile

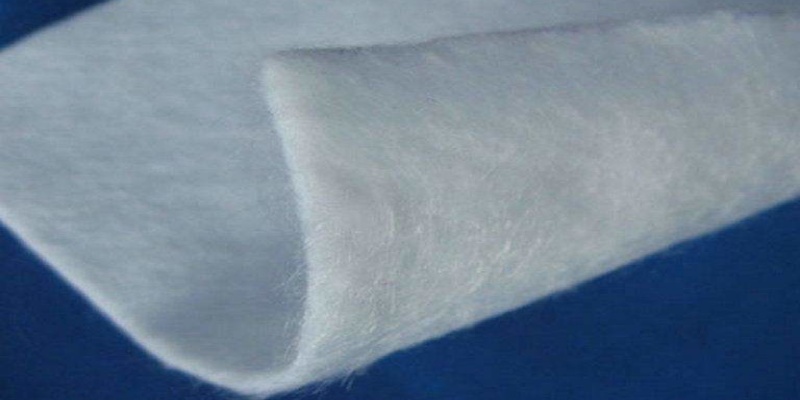

The random, three-dimensional fiber structure of nonwoven geotextile allows water to pass freely while preventing soil particle migration. It ensures efficient drainage and long-term filtration performance in roadbeds, retaining walls, and drainage systems.

Needle-punched nonwoven fabrics provide high elongation and soft handling, enabling the fabric to conform to irregular ground surfaces without tearing or wrinkling. This flexibility makes installation easier even on uneven terrain.

Nonwoven geotextile effectively separates different soil layers, preventing intermixing and loss of bearing capacity. It also serves as a cushioning layer to protect geomembranes or waterproof liners from puncture and mechanical damage.

Made from stable polymers like PET (polyester) or PP (polypropylene), nonwoven geotextile resists chemical corrosion, acids, alkalis, and biological degradation—ensuring long-term durability even in harsh environments such as landfills and wastewater treatment projects.

UV-stabilized nonwoven fabrics maintain mechanical integrity and color stability under prolonged sunlight exposure, suitable for open-air applications like slope protection or embankments.

The interlocked fiber matrix maintains shape and performance under compaction and repeated loading, ensuring consistent separation and filtration over time.

Flexible rolls are lightweight and simple to cut, overlap, and join, significantly reducing labor and equipment costs on site.

Get to Know Woven Geotextile Fabric

A nonwoven geotextile is a permeable fabric made from polyester (PET) or polypropylene (PP) fibers that are mechanically bonded through needle punching or thermal bonding. It is used for separation, filtration, protection, and drainage in civil and environmental engineering projects.

Nonwoven geotextile is widely used in road construction, slope protection, landfill liners, and drainage systems. It prevents soil mixing, allows controlled water flow, and protects geomembranes from puncture, making it essential in geotechnical and environmental applications.

There are mainly two types of nonwoven geotextiles:

Continuous Filament Nonwoven Geotextile: made from long, continuous PET or PP filaments for high strength and durability.

Staple Fiber Nonwoven Geotextile: made from short synthetic fibers, offering excellent flexibility and filtration performance.

The standard weight of nonwoven geotextile typically ranges from 100 gsm to 800 gsm, depending on project requirements. Lighter fabrics are used for filtration and drainage, while heavier types (≥400 gsm) are designed for protection and stabilization applications.

Yes. Nonwoven geotextiles have a three-dimensional pore structure that allows water to pass through while retaining soil particles. This makes them ideal for filtration and subsurface drainage in roadbeds, retaining walls, and reservoirs.

High-quality nonwoven geotextile fabric can last more than 20 years in buried applications and 5–10 years in exposed conditions. When UV-stabilized, it resists sunlight and weathering, ensuring long-term performance in demanding environments.

Types of Non Woven Geotextile

PET Continuous Filament Nonwoven Geotextile

Polyester continuous filament nonwoven geotextile is produced by spunbond and needle-punched processes to form a stable three-dimensional structure. It features high tensile strength, dimensional stability, and resistance to UV, oxidation, and biological degradation. This durable polyester nonwoven fabric provides excellent filtration and permeability, making it ideal for roadbed stabilization, dam construction, tunnels, and landfill lining. It performs effectively in drainage and separation applications across civil and geotechnical projects.

PP Continuous Filament Nonwoven Geotextile

Polypropylene continuous filament nonwoven geotextile combines lightweight handling with excellent chemical and acid–alkali resistance. The uniform filament structure ensures controlled permeability and long-term filtration efficiency under load. Commonly used in sewage treatment, drainage systems, coastal embankments, and filtration works, it maintains strength and performance in harsh environments. This PP nonwoven geotextile is widely adopted in industrial, municipal, and environmental engineering projects requiring chemical stability and high flow capacity.

PET Staple Fiber Nonwoven Geotextile

PET staple fiber nonwoven geotextile is made from high-strength polyester short fibers bonded by a needle-punched process. It offers high puncture resistance, flexibility, and durable filtration capability. The dense yet permeable structure prevents soil migration while allowing water to pass freely. Ideal for slope protection, tunnel lining, road construction, and waterproofing systems, this polyester short fiber geotextile provides long-lasting separation, drainage, and reinforcement in infrastructure and hydraulic applications.

PP Staple Fiber Nonwoven Geotextile

Polypropylene staple fiber needle-punched nonwoven geotextile provides an economical and versatile solution for filtration, drainage, separation, and erosion control. It features high chemical resistance, soft texture, and ease of installation, suitable for landscape, highway, and environmental protection projects. The open fiber structure promotes rapid water flow while retaining soil particles, ensuring long-term stability of soil systems in both civil engineering and environmental containment works.

Customization options of Non-Woven ceotextile

| Product Type | Tensile Strength (MD/CD) | Unit Weight (g/m² · oz/yd²) | Roll Width (m) | Application Range |

|---|---|---|---|---|

| PET Continuous Filament Nonwoven | 20–60 kN/m (≈ 12–34 kN/ft) | 100–800 g/m² (≈ 2.9–23.6 oz/yd²) | 1.0–7.0 m (customized) | Used for roadbeds, dams, tunnels, landfills and other civil works requiring high strength, filtration, and drainage. |

| PP Continuous Filament Nonwoven | 15–50 kN/m (≈ 9–29 kN/ft) | 100–800 g/m² (≈ 2.9–23.6 oz/yd²) | 1.0–7.0 m (customized) | Applied in drainage layers, coastal protection, sewage treatment, and filtration projects with chemical resistance requirements. |

| PET Staple Fiber Nonwoven | 10–40 kN/m (≈ 6–23 kN/ft) | 100–800 g/m² (≈ 2.9–23.6 oz/yd²) | 1.0–7.0 m (customized) | Ideal for slope protection, tunnel waterproofing, and foundation separation requiring durable and flexible filtration performance. |

| PP Staple Fiber Nonwoven | 8–30 kN/m (≈ 5–17 kN/ft) | 100–800 g/m² (≈ 2.9–23.6 oz/yd²) | 1.0–7.0 m (customized) | Used for filtration, drainage, separation, and landscaping in municipal and environmental protection projects. |

Typical Choice of Non Woven ceotextile

| Project Scenario | Recommended Product Type | Tensile Strength (MD/CD) | Unit Weight (g/m² · oz/yd²) | AOS (mm) | Remarks / Key Benefit |

|---|---|---|---|---|---|

| Road & railway subgrade stabilization (highways, embankments) |

PET Continuous Filament Nonwoven | 20–60 kN/m | 200–600 g/m² (≈ 5.9–17.7 oz/yd²) | 0.06–0.15 | High tensile & puncture resistance; improves base separation and stability under heavy loads. |

| Drainage & filtration systems (retaining walls, subsoil drains) |

PP Continuous Filament Nonwoven | 15–50 kN/m | 150–500 g/m² (≈ 4.4–14.7 oz/yd²) | 0.08–0.18 | Excellent permeability and clogging resistance; maintains water flow while retaining fine soil particles. |

| Slope protection & erosion control (riverbanks, reservoirs, slopes) |

PET Staple Fiber Nonwoven | 10–40 kN/m | 150–700 g/m² (≈ 4.4–20.6 oz/yd²) | 0.10–0.25 | Durable and flexible for uneven terrain; prevents soil erosion and improves slope stability. |

| Landfill base & leachate collection (municipal & hazardous waste) |

PET Continuous Filament Nonwoven | 25–60 kN/m | 300–800 g/m² (≈ 8.8–23.6 oz/yd²) | 0.06–0.12 | High chemical resistance and filtration efficiency; ideal as protection and drainage layer above geomembranes. |

| Underground waterproofing & tunnels (metro, culverts, basements) |

PET Continuous Filament Nonwoven | 20–55 kN/m | 200–500 g/m² (≈ 5.9–14.7 oz/yd²) | 0.08–0.18 | Enhances waterproofing membranes, absorbs pressure, and ensures long-term drainage behind lining structures. |

| Coastal & marine engineering (revetments, dikes, reclamation) |

PP Continuous Filament Nonwoven | 15–45 kN/m | 200–600 g/m² (≈ 5.9–17.7 oz/yd²) | 0.08–0.20 | Resists saltwater corrosion; provides separation and filtration under hydraulic structures. |

| Municipal & landscaping works (gardens, artificial lakes, parking lots) |

PP Staple Fiber Nonwoven | 8–25 kN/m | 100–400 g/m² (≈ 2.9–11.8 oz/yd²) | 0.12–0.25 | Lightweight and cost-effective; prevents soil contamination and improves surface drainage. |

| Mining & industrial drainage (heap leach pads, tailings ponds) |

PET Staple Fiber Nonwoven | 15–45 kN/m | 300–800 g/m² (≈ 8.8–23.6 oz/yd²) | 0.10–0.20 | Provides filtration and puncture protection; ensures stability in leachate and drainage layers. |

Now Woven Geotextile Testing Standards

| Property | Test Method (ASTM / ISO / GB) | Typical Range (PET Nonwoven) | Typical Range (PP Nonwoven) | Remarks / Key Performance |

|---|---|---|---|---|

| 1. Physical Properties | ||||

| Unit Weight | ASTM D5261 / ISO 9864 | 100–800 g/m² | 100–600 g/m² | Determines product mass and grade selection. |

| Thickness (2 kPa) | ASTM D5199 / ISO 9863 | 0.8–5.0 mm | 0.6–4.5 mm | Related to cushioning and permeability capacity. |

| 2. Mechanical Properties | ||||

| Tensile Strength (MD/CD) | ASTM D4595 / ISO 10319 | 20–60 kN/m | 15–50 kN/m | Measures fabric strength and elongation under load. |

| Elongation at Break | ASTM D4595 / ISO 10319 | 40–80% | 50–100% | Indicates flexibility and deformation capacity. |

| Tear Strength | ASTM D4533 / ISO 9073-4 | 200–600 N | 150–500 N | Resists tearing during installation and handling. |

| Puncture Strength | ASTM D4833 / ISO 12236 | 500–2500 N | 400–2000 N | Indicates resistance against stone or gravel penetration. |

| 3. Hydraulic Properties | ||||

| Apparent Opening Size (AOS) | ASTM D4751 / ISO 12956 | 0.06–0.20 mm | 0.08–0.25 mm | Controls filtration and soil retention efficiency. |

| Permittivity | ASTM D4491 / ISO 11058 | 0.5–1.5 s⁻¹ | 0.8–2.0 s⁻¹ | Indicates water flow capacity perpendicular to fabric plane. |

| 4. Durability & Chemical Resistance | ||||

| UV Resistance (500 h) | ASTM D4355 | ≥70% strength retained | ≥65% strength retained | Ensures weather resistance in exposed applications. |

| Chemical Resistance | ASTM D543 / ISO 13438 | Excellent | Excellent | Stable against acids, alkalis, and biological degradation. |

Non-Woven Geotextile Installation & Quality Control (CQA)

Laying Methods

Surface Preparation:

Before installation, make sure the subgrade is smooth, well-compacted, and free of sharp stones, roots, or debris that may damage the fabric. Remove any standing water and repair soft or uneven areas to ensure a stable foundation.

Fabric Placement:

Unroll the nonwoven geotextile evenly on the prepared surface without stretching or wrinkling. The fabric should be laid in the same direction as the slope or water flow to maintain continuous drainage paths and filtration efficiency.

Overlap and Seaming:

Adjacent panels should overlap by 30–50 cm in flat areas and up to 1.0 m on slopes or underwater projects. Seams may be joined using thermal bonding or double-thread stitching, ensuring overlap joints are placed away from areas of high stress or concentrated loads.

Anchoring:

In exposed applications such as slopes, dams, or shore protection, anchor the edges of the fabric in trenches approximately 30×30 cm deep. Backfill with compacted soil or gravel to prevent wind uplift or water movement.

Protective Layer:

For drainage or geomembrane protection systems, immediately cover the geotextile with sand, gravel, or soil to prevent ultraviolet exposure and mechanical damage. Heavy equipment should never drive directly over the fabric.

Weather Considerations:

Avoid installation during strong wind, rain, or freezing conditions. In cold climates, handle rolls gently to prevent fiber cracking or delamination caused by low temperatures.

Quality Control & Inspection

Check that all delivered rolls meet the required specifications for weight, thickness, tensile strength, and permeability according to ASTM or ISO standards.

Visual Inspection:

Inspect the fabric before installation for holes, tears, oil stains, or mechanical damage. Any defective areas must be cut out and replaced with new material.

Seam Quality Check:

For stitched seams, ensure the joint strength meets at least 80% of the parent material strength as per ASTM D4884. The stitching should be consistent, tight, and free of skipped or broken threads.

Documentation:

Record roll numbers, laying direction, overlap widths, weather conditions, and installation progress. Keep all test certificates and CQA reports as part of the project documentation.

Final Protection:

Once installed, cover the nonwoven geotextile as soon as possible and avoid sunlight exposure for more than 14 days unless UV-stabilized material is used.

Why Choose WP Specialist?

Over the years, WP Specialist has built a strong reputation as one of China’s trusted woven geotextile manufacturers and global suppliers of geosynthetic materials.

We focus on delivering reliable non woven fabrics that meet the demanding needs of civil, road, and hydraulic engineering projects worldwide.

Our woven geotextiles combine high tensile strength, stability, and consistent quality — backed by factory-direct service and technical expertise.

- Free Samples of Non Woven Geotextile Fabric

- Expert Project Support

- Reliable Quality Assurance

- Over 10 Years of Manufacturing Experience

- Factory Direct Supply

Ready to Specify a Geotextile?

- 15+ Years of Factory-Direct Expertise

- Custom-Engineered Solutions for Your Needs

- Global Shipping & Logistics Support

- A Transparent, No-Obligation Quote

- 100% Confdentiality Guaranteed

Your email information will be kept strictly confdential and our business staff will ensurethat your private information is absolutely safe!

Contact

- info@waterproofspecialist.com

Reply within 12 hours!

Please pay attention to the email with the suffix “@waterproofspecialist.com”.